📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

In the relentless world of modern logistics, stagnation is the same as regression. The traditional warehouse, with its bolted-down, rigid storage systems, represents a monumental capital commitment to a single, frozen moment in a company’s evolution. This static approach is a high-stakes gamble, often resulting in crippling inefficiency when business outgrows the space or wasteful underutilization when projections fall short. The antidote to this inflexibility is the strategic adoption of a modular platform for warehouses.

This concept transcends the definition of simple shelving; it represents a holistic, integrated ecosystem of storage structures, material handling equipment, and intelligent software, all designed with a singular, powerful purpose: to evolve in perfect synchrony with the business it serves. A true modular platform for warehouses transforms storage from a fixed liability into a dynamic, scalable asset, enabling companies to scale storage operations effortlessly, responding with agility to market demands and growth opportunities.

This comprehensive guide delves into the operational philosophy, structural components, and strategic implementation of the modern modular platform for warehouses. It will explore how this system directly addresses the core challenges of contemporary supply chains, from e-commerce volatility to the seamless integration of automation. The objective is to provide a master-level understanding of how a modular platform for warehouses is not merely an investment in physical infrastructure, but a foundational commitment to operational resilience and future-proof growth.

<h2>Beyond Static Racking: The Strategic Imperative of a Modular Warehouse Platform</h2>

The fundamental flaw of conventional warehouse design is its inherent permanence. It operates on a forecast-driven model that is increasingly obsolete in a world of rapid shifts. A modular platform for warehouses is architected on a principle of responsive adaptability. It is a system built not for a predicted future, but for an uncertain one, providing the operational flexibility that modern commerce demands.

Envision the difference between carving a statue from a single block of marble versus constructing a sophisticated model with engineered, interlocking components. The former allows for no error; the latter can be reconfigured, expanded, and improved indefinitely. This is the core strength of a modular platform for warehouses. It grants logistics managers three critical strategic freedoms that static systems cannot offer:

The Freedom of Elastic Scalability: A sudden contract win or a seasonal surge no longer necessitates a panic-driven search for additional warehouse space or a costly, permanent expansion. A well-designed modular platform for warehouses can be expanded vertically with additional mezzanine levels or laterally with new storage modules, all using the same standardized components. This scalability is bidirectional; during market contractions, the system can be rationally condensed to reduce the physical footprint and associated costs, protecting the bottom line.

The Freedom of Continuous Reconfiguration: Operational efficiency is not a one-time achievement but a continuous pursuit. Product velocity profiles change, new SKUs are introduced, and picking strategies must evolve. A modular platform for warehouses allows the entire storage layout to be redesigned and reassembled to mirror these new realities. Aisles can be widened for new equipment, slow-moving items can be shifted to high-density storage, and dynamic pick zones can be created overnight, all without welding torches or massive downtime.

The Freedom of Technological Integration: Perhaps the most significant advantage, a modular platform for warehouses is conceived from the outset as the native habitat for automation. The structures are engineered with clear sightlines, standardized dimensions, and robust data connectivity points, making them inherently ready to collaborate with Automated Guided Vehicles (AGVs), Autonomous Mobile Robots (AMRs), and automated storage and retrieval systems (AS/RS). Investing in a modular platform for warehouses is, in effect, building the ready-and-waiting infrastructure for the automation technologies of tomorrow.

<h3>The Hidden Economics: Calculating the Total Cost of Inflexibility</h3>

Many procurement decisions are myopically focused on the upfront price per pallet position. This is a critical miscalculation. The true metric for any capital expenditure in logistics is the Total Cost of Ownership (TCO) over a 10 to 15-year horizon. A cheap, static storage system accrues a devastatingly high TCO through several hidden channels:

Perpetual Space Inefficiency: Fixed layouts inevitably create unusable “dead” zones and inefficient cubing, leading to a perpetually elevated cost per square foot of usable storage.

Compounding Labor Inefficiencies: Inflexible layouts force workers into suboptimal pick paths and restocking routines. Over years, the compounded cost of extra footsteps and minutes per pick represents a massive, recurring financial drain.

Catastrophic Capital Events: When growth finally breaches the physical limits of a static system, the business faces a multimillion-dollar dilemma: fund a devastatingly expensive new facility or endure a highly disruptive total system replacement.

Innovation Paralysis: A warehouse locked into a fixed structure is a warehouse unable to adopt new technologies. The capital and operational cost of retrofitting static racking for automation is often prohibitive, causing companies to fall behind more agile competitors.

A strategically implemented modular platform for warehouses systematically dismantles these hidden costs, resulting in a lower, more predictable, and more efficient TCO.

<h2>Anatomic Analysis: The Core Components of a High-Performance Modular Platform for Warehouses</h2>

To understand the power of this approach, one must look under the hood. A best-in-class modular platform for warehouses is a synergistic combination of physical engineering and digital intelligence.

<h3>The Physical Framework: Engineered for Change</h3>

The physical component of a modular platform for warehouses is where the principle of adaptability is made tangible.

True Modular Pallet Racking: Far surpassing standard bolt-together racking, the advanced modular platform for warehouses utilizes systems with patented, tool-less locking mechanisms. Beams can be repositioned in seconds by a single worker, and entire bay frames can be disassembled and reconfigured without discarded parts or specialized contractors. This forms the scalable backbone for bulk pallet storage.

Adaptive Carton Flow & Dynamic Storage: For high-velocity case picking, a modular platform for warehouses integrates fully adaptable carton flow systems. These roller or wheel-based lanes are themselves modular units that can be linked, extended, or rearranged to create optimal pick faces that directly reflect real-time SKU velocity, a feature impossible in a static system.

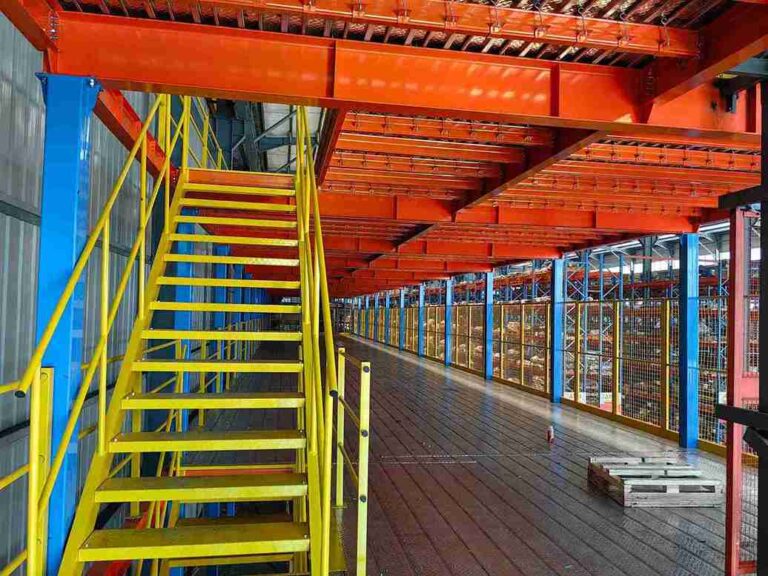

Structural Mezzanines as Scalable Tiers: When the footprint is maxed out, the only direction is up. A modular platform for warehouses often incorporates engineered structural mezzanines. These are not custom-welded structures but are comprised of pre-designed, bolt-together components that can be expanded in area or even in height, effectively creating a second or third floor within the existing building envelope, a powerful demonstration of scalable density.

Mobile Shelving Systems for Maximum Density: For parts storage, archives, or kitting operations, a modular platform for warehouses can include high-density mobile shelving carriages. These systems eliminate fixed aisles, allowing shelves to be packed tightly together and aisles to be opened only where needed, dramatically increasing storage density within a flexible framework.

<h3>The Digital Cortex: The Intelligence Layer</h3>

A flexible physical structure is powerful, but it is the integration with a Warehouse Management System (WMS) that transforms a modular platform for warehouses into a cognitive, responsive organism.

Predictive Layout Simulation with Digital Twins: Prior to any physical change, the WMS linked to the modular platform for warehouses can run complex simulations within a digital twin of the facility. Planners can model the impact of a new product launch, a 200% sales surge, or a new cross-docking procedure, ensuring every reconfiguration is validated by data before a single component is moved.

Prescriptive Dynamic Slotting: A static warehouse has stagnant slotting. A modular platform for warehouses empowered by a smart WMS enables prescriptive dynamic slotting. The system continuously analyzes pick data, travel paths, and product correlations, then proactively recommends specific layout changes, stating, for example, “Relocating these 15 SKUs to Zone B will reduce total daily travel distance by 1.2 miles.”

Real-Time Inventory Synchronization: As the physical layout of the modular platform for warehouses changes, the WMS automatically and instantly updates all location data. This seamless synchronization ensures 100% inventory visibility and accuracy, eliminating the errors and delays that typically plague warehouse reconfigurations.

<h3>The Kinetic Force: Seamless Automation Integration</h3>

This is the ultimate differentiator for a modern modular platform for warehouses. It is designed to be a collaborative partner with robotics and automation.

AGVs and AMRs as Native Inhabitants: The uniformity, clear aisles, and standardized pathways of a modular platform for warehouses create the ideal operating environment for AGVs and AMRs. The predictability of the layout allows for optimized robot navigation. Crucially, when the modular platform for warehouses is reconfigured, the digital map for the robots can be updated swiftly, maintaining a fluid symbiosis between the physical and digital worlds.

Modular AS/RS Solutions: Beyond large, fixed AS/RS, there is a growing category of modular, shuttle-based AS/RS that are designed to be installed within the racking of a modular platform for warehouses. This allows a company to start with a single automated aisle and scale the automation by adding more shuttles and storage columns as throughput requirements increase, a perfect alignment with the scalable philosophy.

Adaptable Conveyor and Sortation Modules: Even conveyor systems benefit from a modular design philosophy within the broader modular platform for warehouses. We design conveyor sections that can be easily extended, rerouted, or integrated with new pack stations or sortation loops, ensuring the entire material flow ecosystem can evolve.

<h2>The Implementation Playbook: Strategically Deploying Your Modular Platform for Warehouses</h2>

Adopting a modular platform for warehouses is a strategic initiative, not a simple procurement. It requires a methodical, phased approach to ensure alignment with business objectives and minimize operational risk.

<h3>Phase 1: Deep-Dive Discovery and Data-Driven Blueprinting</h3>

The foundation of a successful modular platform for warehouses is laid with data, not assumptions.

Granular SKU and Process Analysis: The process begins with a forensic analysis of 12-36 months of operational data—SKU velocity, seasonality, order profiles, and inventory turns. This is combined with detailed process mapping to identify every bottleneck and inefficiency in the current flow.

Strategic Growth Alignment: We conduct workshops with executive leadership to understand the 3-5 year strategic plan. Are new markets being entered? Are new product verticals being added? Is a shift to direct-to-consumer fulfillment planned? The modular platform for warehouses must be designed to facilitate these specific strategic goals.

Conceptual Simulation and Validation: Using advanced simulation software, we create and stress-test multiple layout concepts for the proposed modular platform for warehouses. This allows stakeholders to visually see how the system will perform under various future scenarios, building confidence and validating the investment.

<h3>Phase 2: Phased, Low-Risk Deployment</h3>

A “big bang” replacement is fraught with risk. A phased rollout of the modular platform for warehouses is the hallmark of a sophisticated implementation.

Pilot Zone for Rapid Value Realization: Implementation often begins in a high-impact area, such as the fast-pick zone or a specific product line’s storage area. This allows for a quick win, demonstrates tangible value, and enables the operational team to build familiarity with the system in a controlled environment.

Staged Technology Integration: The beauty of a modular platform for warehouses is that the automation does not have to come all at once. The physical structure is deployed as “automation-ready.” A company can install the modular platform for warehouses and WMS in Phase 1, and then seamlessly integrate a fleet of AGV pallet trucks in Phase 2, when the business case is solidified. The platform patiently waits for the technology.

Execution with Operational Continuity: Our project teams are specialists in working within live distribution environments. We develop meticulous phasing plans that allow us to construct new sections of the modular platform for warehouses while the business continues to operate in the old layout, ensuring that daily fulfillment is never compromised.

<h3>Phase 3: The Cycle of Continuous Optimization</h3>

Once the modular platform for warehouses is operational, the relationship shifts from implementation to a long-term partnership focused on continuous improvement.

Strategic Quarterly Business Reviews (QBRs): These are not mere maintenance check-ins. They are strategic sessions where we review performance data against KPIs and, most importantly, discuss upcoming business initiatives. The conversation is forward-looking: “Your new marketing campaign launches in Q3; let’s proactively reconfigure the pick module next month to accommodate the expected SKU velocity shift.”

Ongoing Software and Training Evolution: The WMS software that powers the modular platform for warehouses is continually enhanced. We ensure your team is trained on these updates, empowering them to leverage new algorithms for slotting, labor management, and predictive analytics.

Agile Inventory and Space Management: The system makes the reallocation of space a routine operational task rather than a capital project. As SKUs are added or phased out, the modular platform for warehouses can be instantly tuned to maintain peak space utilization and picking efficiency.

<h2>Case in Point: The 3PL Transformation via a Modular Platform for Warehouses</h2>

Consider the real-world challenge of a third-party logistics (3PL) provider. Their entire business model is predicated on volatility—clients onboarding and offboarding, dramatic seasonal peaks, and a constantly churning SKU mix. Their previous static racking system was a core operational constraint; each new client required a week of disruptive, expensive reconfiguration, and their picking efficiency was chronically poor, eroding margins.

The implementation of a comprehensive modular platform for warehouses was transformative. The solution included:

A backbone of truly modular pallet racking in the bulk storage area.

A large, fully reconfigurable carton live storage system for the fastest-moving SKUs.

A advanced WMS with prescriptive dynamic slotting capabilities.

Aisles and structures explicitly designed to be “AGV-ready.”

The results were decisive. The time required to onboard a new client was slashed by over 80%. Overall pick efficiency surged by 35% within the first year, as the layout could be continuously optimized based on real data. When a major e-commerce client experienced an unexpected 200% sales surge during the holiday season, the 3PL was able to rapidly expand the dedicated storage zone and re-optimize pick paths within days, not weeks.

This agility not only saved the contract but became a powerful selling point for attracting new, demanding clients. The modular platform for warehouses provided a definitive competitive advantage: the operational resilience to confidently say “yes” to complex, evolving client needs.

<h2>Conclusion: The Paradigm Shift—From Building Warehouses to Cultivating Platforms</h2>

The age of the static warehouse is conclusively over. In its place, the strategic imperative is the agile, intelligent, and endlessly scalable modular platform for warehouses. This is not a product one simply buys, but a long-term partnership with an infrastructure that learns, adapts, and grows with the business.

It is the ultimate tool for de-risking logistics in an unpredictable global economy. By investing in a modular platform for warehouses, a company is not just purchasing storage; it is investing in resilience, operational excellence, and the foundational capacity for limitless growth. The central question for any growing business is no longer if they can scale their storage, but how effortlessly their chosen modular platform for warehouses will enable them to do so.

Frequently Asked Questions (FAQs)

1. How does the structural integrity and safety of a modular platform for warehouses compare to traditional, welded racking?

This is a paramount concern, and rightly so. A professional-grade modular platform for warehouses is engineered to meet and often exceed all national and international safety standards for storage equipment, including the rigorous RMI/ANSI MH16.1 standard. The key difference lies in the connection technology.

Instead of relying on bolts that can loosen over time, high-end modular systems use precision-engineered, positive-locking mechanisms that often provide superior resistance to dynamic forces, such as seismic activity or impacts from material handling equipment. The integrity of a modular platform for warehouses is a function of its engineered design and quality manufacturing, not the permanence of its connections.

2. Our facility has a highly irregular layout with numerous columns and fixed obstructions. Can a modular platform for warehouses still be effective?

Absolutely. In fact, challenging and irregular spaces are where the inherent flexibility of a modular platform for warehouses provides its most dramatic value. Unlike pre-engineered, rigid systems that require a perfect rectangle, a modular platform for warehouses is designed to be tailored to the exact contours of your building.

Components can be custom-cut and layouts can be creatively designed to snake around columns, maximize space in odd-shaped corners, and turn architectural obstacles into integrated parts of the storage plan. This ability to create a bespoke, optimized layout from standardized components is a core strength of the system.

3. What is the typical lead time for a significant expansion of an existing modular platform for warehouses?

Lead times for expanding a modular platform for warehouses are consistently and dramatically shorter than for a new, traditional custom system. Because the platform is built from a standardized kit of parts, the required components are typically held in stock or have very short manufacturing lead times.

A large-scale expansion that might require a 12-16 week lead time for a custom system can often be deployed in 4-6 weeks with a modular platform for warehouses. Furthermore, the on-site installation is exponentially faster due to the simplified, tool-less assembly process, minimizing disruption to your ongoing operations.

4. Is it feasible to retrofit or upgrade our existing static racking into a modular platform for warehouses, or is a full system replacement necessary?

While partial integration is sometimes technically possible, it is often a sub-optimal path that dilutes the core benefits. The true power of a modular platform for warehouses comes from the seamless interoperability of all components—the racking, the mezzanines, the software integration, and the automation readiness—from a unified design.

Retrofitting old racking rarely achieves this holistic synergy. A full system replacement, while a larger initial investment, ensures you fully capitalize on the reconfigurability, data integration, and future-proofing that defines a true modular platform for warehouses. A professional audit can assess your current assets and provide a clear TCO analysis of retrofitting versus a new implementation.

5. How can you possibly future-proof a modular platform for warehouses against automation technologies that haven’t been invented yet?

We achieve this not by predicting specific technologies, but by embedding future-proofing principles into the very design of the modular platform for warehouses. This involves:

Standardized Operational Envelopes: Designing for clear aisle widths, standard load beam heights, and uniform floor conditions that serve as a universal “highway” for any mobile robot.

Structural Over-Engineering: Engineering the structure with additional capacity for the potential dynamic loads and data conduit requirements of unknown future automation.

Open-Architecture Data Infrastructure: Ensuring the WMS and network backbone use open APIs and have ample bandwidth, creating a “conversational” platform that can communicate with future systems. We build the adaptable stage, ready for whatever performance the next act of technological innovation brings.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com