📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Critical Imperative of Vertical Space Optimization

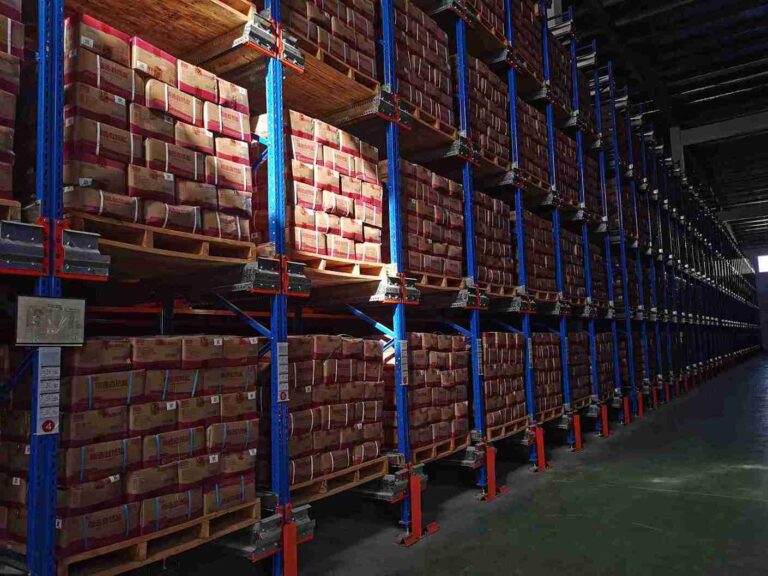

In the high-stakes world of logistics and supply chain management, the warehouse is no longer a passive storage facility; it is the dynamic, pulsating heart of the operation. The efficiency of this heart directly dictates the health of the entire business organism. For countless operations managers, logistics directors, and business owners, a persistent and costly challenge looms overhead—literally. The vast, often empty, vertical airspace above the storage racks represents the final frontier for operational optimization.

While traditional shelving and even standard automated systems have made incremental improvements, the quantum leap in performance is achieved through a highly tailored approach. The solution lies not merely in adopting shuttle racking technology, but in meticulously engineering its shuttle racking customization features to fit the unique fingerprint of an operation.

This article delves into the five most impactful shuttle racking customization features that sophisticated providers leverage to help businesses not just hope for, but engineer an 80% or greater increase in storage density, thereby transforming a major cost center into a formidable competitive advantage.

H2: The Paradigm Shift: From Off-the-Shelf Product to Bespoke Engineered Solution

The fundamental differentiator between a mediocre investment and a transformative one is the perspective on the system itself. A standard shuttle racking system is a product—a commodity with fixed parameters. A system defined by advanced shuttle racking customization features is an engineered solution. It represents a shift from forcing a business’s inventory, workflows, and growth projections to conform to the limitations of a machine, to having a machine designed as an extension of the business’s operational logic.

The most critical shuttle racking customization features are born from a deep-dive discovery process that analyzes SKU velocity, physical dimensions, weight distributions, throughput requirements, and future expansion plans. This philosophy of bespoke engineering is what unlocks the true potential of high-density storage, making the specific shuttle racking customization features discussed below the levers for achieving unparalleled cube utilization.

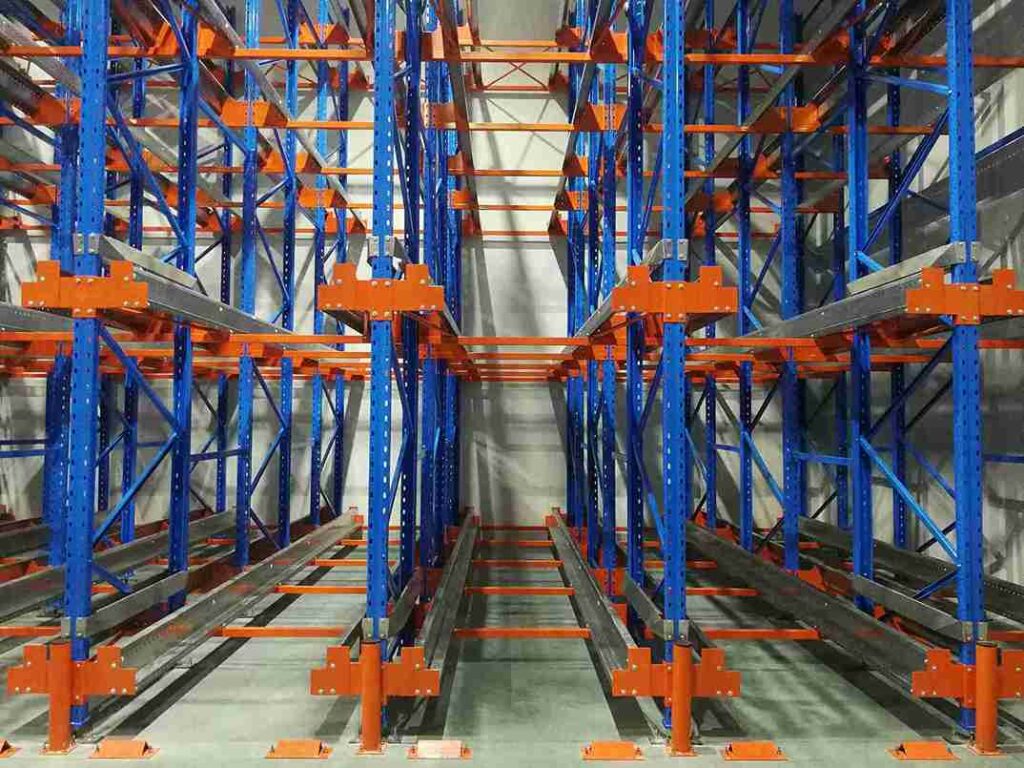

H3: The Foundational Audit: Data-Driven Design as the First Customization Feature

Before a single beam is designed, the most crucial phase begins: the comprehensive operational and facility audit. This stage is, in itself, the primary customization feature. Experts don’t assume; they measure, analyze, and model. This process involves:

Granular SKU Analysis: Cataloging every stock-keeping unit’s footprint, weight, stackability, and turnover rate. This data forms the immutable blueprint for all physical shuttle racking customization features.

Throughput Velocity Mapping: Understanding the flow of goods—peak seasons, daily shifts, and required order turnaround times. This informs the performance requirements of the automated components.

Facility Topography Scanning: Using advanced laser scanning to create a precise 3D model of the existing warehouse, capturing every column, truss, sprinkler head, and floor irregularity. This ensures the designed system maximizes every possible cubic inch.

This rigorous, data-first approach ensures that every subsequent shuttle racking customization features recommendation is grounded in empirical reality, not estimation.

H2: Custom Shuttle Racking Feature #1: Precision-Engineered Lane Depth and Configuration

H3: The Limitations of Standardized Lane Designs

Standard systems often utilize a one-size-fits-all approach to lane depth, which is a primary source of inefficiency. Lanes that are too long for the pallet create dead space, wasting potential storage positions. Lanes that are too short or not configured for deeper storage strategies limit density gains from the outset. The first set of critical shuttle racking customization features addresses this exact issue, treating lane geometry as a variable to be optimized.

H3: Tailored Depth as a Core Customization Feature

The ability to specify the exact lane depth and configuration is a foundational shuttle racking customization features pillar. This goes beyond simple length adjustment, encompassing strategic layouts:

Dynamic Lane Assignment: For facilities with a mix of pallet sizes, a key shuttle racking customization features is designing lanes of varying depths within the same aisle. This allows a single aisle to efficiently store different SKUs without wasting an entire aisle on a non-standard size.

High-Density Push-Back Configuration: A powerful shuttle racking customization features is the integration of push-back mechanics within the shuttle lane. This allows for storage of pallets 3 to 5 deep, significantly increasing density compared to selective racking while maintaining better accessibility than drive-in systems.

FIFO/LIFO Compliance through Design: Whether a business requires First-In-First-Out or Last-In-First-Out inventory management, the lane configuration can be custom-designed as a shuttle racking customization features to enforce this logic at the hardware level, ensuring operational integrity.

By treating lane depth as a flexible parameter, these shuttle racking customization features ensure that the system’s footprint is used with mathematical precision, laying the groundwork for massive density improvements.

H2: Custom Shuttle Racking Feature #2: Optimized Vertical Bay Height and Multi-Tiered Structures

H3: Capitalizing on the Vertical Cube

The most visually obvious opportunity for increasing density is vertical space. Standard systems have practical height limits based on their structural design. A suite of advanced shuttle racking customization features is focused specifically on safely and efficiently building upwards to the absolute maximum of a facility’s clear height.

H3: Structural and Operational Engineering for Height

The shuttle racking customization features related to height are among the most technically complex, involving structural engineering and precision mechanics:

Heavy-Duty Structural Fabrication: This shuttle racking customization features involves calculating the required steel gauge, upright column profile, and bracing systems to create a structure capable of handling the immense loads at significant heights, often exceeding 100 feet, while maintaining stability.

Tiered Shuttle and Lift Synchronization: A critical shuttle racking customization features is the design of the vertical lift mechanism that services the multiple tiers of shuttle rails. The lift’s speed, capacity, and positioning accuracy are customized to match the throughput demands, ensuring that height does not become a bottleneck for speed.

Safety Integration at Elevation: Custom safety protocols, including redundant sensors and secure pallet handling mechanisms at every tier, are non-negotiable shuttle racking customization features for high-rise systems, protecting both the inventory and the system integrity.

These vertical shuttle racking customization features are often the single largest contributor to the target density increase, effectively multiplying the storage capacity of the existing floor area.

H2: Custom Shuttle Racking Feature #3: Advanced Load-Beam and Decking Specifications

H3: Accommodating the Real-World Inventory

Warehouses store products, not idealized pallets. Many operations deal with post pallets, slip sheets, unstable loads, or unusually heavy items. A standard system might force a change in packaging or pose a safety risk. The shuttle racking customization features related to the direct support structure are designed to accommodate this reality.

H3: Engineering the Interface Between System and Load

This category of shuttle racking customization features requires detailed knowledge of materials science and structural dynamics:

Custom Beam Profiles and Capacities: For exceptionally heavy loads, such as automotive parts or industrial materials, a vital shuttle racking customization features is the design of reinforced load beams with higher weight capacities and specific profiles to ensure deflection remains within safe limits.

Specialized Decking Solutions: Whether for ventilation (wire mesh), containment (solid steel), or specific handling needs (roller decks), the choice of decking is a practical shuttle racking customization features that directly impacts what can be stored and how safely.

Non-Standard Pallet Supports: Designing custom brackets, arms, or shelves to securely hold post pallets or other non-standard unit loads is a niche but critical shuttle racking customization features for industries like beverages or manufacturing.

By focusing on these often-overlooked shuttle racking customization features, engineers ensure that the theoretical density of the system can be fully realized with the actual inventory, without compromise.

H2: Custom Shuttle Racking Feature #4: Intelligent, Integrated Control and Warehouse Software

H3: The Cognitive Core of the Storage System

If the racking is the skeleton and the shuttles are the muscles, the software is the central nervous system. Viewing software as a set of configurable options is a mistake; the most impactful shuttle racking customization features reside in the intelligence layer. This is where storage density is actively managed and optimized in real-time.

H3: Custom Logic and Integration as a Dynamic Feature

The software-related shuttle racking customization features transform a static storage array into a dynamic, self-optimizing asset:

Dynamic Slotting Algorithms: Perhaps the most intelligent of all shuttle racking customization features, this involves programming the Warehouse Control System (WCS) with business rules to automatically place high-velocity SKUs in the most accessible locations, minimizing retrieval times and continuously optimizing space usage as inventory changes.

Seamless WMS/ERP Integration: A cornerstone of modern shuttle racking customization features is building a robust, two-way communication bridge between the shuttle system’s WCS and the company’s broader Warehouse Management System (WMS) or Enterprise Resource Planning (ERP) software. This ensures real-time, flawless inventory visibility.

Predictive Analytics and Performance Dashboards: Advanced shuttle racking customization features include dashboards that provide insights into space utilization percentages, shuttle travel distances, and predictive maintenance alerts, enabling proactive management and continuous improvement.

These software-driven shuttle racking customization features ensure that the physical density achieved by the hardware is fully leveraged through operational excellence, making the system smarter over time.

H2: Custom Shuttle Racking Feature #5: Inherent Modularity and Strategic Scalability

H3: Designing for the Business of Tomorrow, Today

A storage system is a long-term capital investment. The final, and perhaps most strategic, set of shuttle racking customization features focuses on future-proofing. A rigid system can become an obstacle to growth, whereas a scalable one is an enabler.

H3: Engineering Flexibility and Growth Potential

The shuttle racking customization features related to scalability are embedded in the initial design philosophy:

Modular Component Architecture: Using a system of standardized, yet heavy-duty, components that can be reconfigured or expanded upon is a fundamental shuttle racking customization features. This includes designing the initial structure with the capacity to add more height or additional aisles in the future.

Easily Scalable Control Systems: Implementing a WCS that can seamlessly accommodate additional shuttles, lifts, and picking stations without a costly and disruptive software overhaul is a critical technical shuttle racking customization features.

Phased Implementation Planning: The ultimate shuttle racking customization features is not a physical component but a service: working with the client to create a master plan that allows for phased installation, aligning the system’s growth with the business’s financial and operational roadmap.

These forward-looking shuttle racking customization features protect the capital investment and ensure that the system remains a competitive asset for decades, adapting to market changes and business growth.

H2: Case in Point: The Mathematical Reality of an 80% Density Increase

To move from theory to tangible reality, consider a typical scenario. A warehouse with 10,000 square feet of space and a 30-foot clear height using traditional selective pallet racking (3 tiers) may hold approximately 800 pallets. By applying the five categories of shuttle racking customization features:

Vertical Customization (Feature #2): Designing a 10-tier system triples the vertical storage.

Lane Depth Customization (Feature #1): Implementing a double-deep configuration doubles the pallets per lane.

Software Optimization (Feature #4): Intelligent slotting minimizes wasted space, increasing effective capacity.

The result is a system holding over 1,500 pallets—an increase exceeding 87%. This figure is not aspirational; it is the direct and calculable outcome of applying these sophisticated shuttle racking customization features.

Conclusion: Density as a Deliberate Outcome of Strategic Customization

Achieving a dramatic increase in storage density is not a happy accident resulting from purchasing advanced equipment. It is the deliberate, engineered outcome of applying a deep understanding of a business’s unique operational data to a flexible and powerful technology platform. The promise of an 80% boost in storage density is directly attainable through the strategic implementation of the five core shuttle racking customization features detailed herein: Precision-Engineered Lane Depth, Optimized Vertical Bay Height, Advanced Load-Beam and Decking Specifications, Intelligent Integrated Control Software, and Inherent Modularity and Scalability.

For business leaders seeking to transform their warehouse from a cost center into a strategic weapon, the path forward is clear: partner with experts who prioritize these critical shuttle racking customization features above all else. The unused vertical cube in a warehouse is the last great untapped asset; the right set of shuttle racking customization features is the key to unlocking its immense value.

H2: Frequently Asked Questions About Shuttle Racking Customization

1: How does the maintenance regimen for a highly customized shuttle system differ from a standard one?

A system built with precision shuttle racking customization features for specific duty cycles often experiences less abnormal wear and tear. Furthermore, a key benefit of these advanced shuttle racking customization features, particularly the software, is predictive maintenance. The system monitors its own health, scheduling maintenance based on usage data, which leads to higher uptime and more predictable operating costs compared to a standard system reliant on reactive repairs.

2: Can a custom shuttle system be integrated with other automation, such as AMRs or sortation systems?

Integration is a primary focus of modern shuttle racking customization features, especially within the control software. The Warehouse Control System (WCS) is designed as a hub to seamlessly coordinate with Autonomous Mobile Robots (AMRs), conveyor systems, and automated sorters. This creates a cohesive, end-to-end automated workflow, a capability that is a direct result of these sophisticated integration shuttle racking customization features.

3: What is the typical lead time from design to commissioning for a fully custom solution?

The timeline is directly influenced by the complexity and scale of the required shuttle racking customization features. A project can range from several months for a moderate system to over a year for a large, highly complex installation. The detailed design phase, where the shuttle racking customization features are finalized, is the most critical and time-intensive, as it ensures a flawless and efficient implementation.

4: Are there specific facility prerequisites, such as floor flatness or column spacing, for a high-density custom system?

Yes, and addressing these is part of the initial audit. High-density systems concentrate significant weight, so floor load capacity is paramount. The design of the shuttle racking customization features will account for existing column grids and may require specific tolerances for floor flatness. A professional provider will identify these requirements upfront and offer solutions, which may include floor reinforcement or design adaptations.

5: What is the process for migrating inventory from an old system to the new custom shuttle system with minimal disruption?

A professional implementation includes a detailed, phased migration plan—a crucial service shuttle racking customization features adjunct. This involves installing the new system in sections, often using temporary operational workflows, and carefully transferring inventory, frequently during off-peak hours. This meticulous planning is essential for a smooth transition that safeguards ongoing operations.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com