📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Where Strategic Precision Meets Unprecedented Speed

In the high-stakes arena of warehouse automation, the delay between conceptualization and execution is where competitive advantage is often lost. For businesses evaluating shuttle racking systems, protracted design cycles and ambiguous proposals represent significant operational risks. A professionally engineered shuttle racking layout design is the non-negotiable foundation of a successful automated storage and retrieval system (ASRS). It transcends mere rack placement, constituting a comprehensive strategy that balances storage density, material flow, total cost of ownership, and future scalability. This article details a transformative service model that delivers a data-driven, dynamically validated custom shuttle racking layout design and an immersive 3D simulation within a 72-hour window, accompanied by a transparent, fixed-price quote.

This process eliminates the traditional weeks-long waiting period, empowering decision-makers to proceed with confidence based on a clear, visual, and quantifiable prototype of their future operation, thereby de-risking a major capital investment from the outset. An optimal shuttle racking layout design unlocks the full cubic potential of a warehouse, ensures peak efficiency of shuttle vehicles, and delivers a measurable, compelling return on investment.

Deconstructing Excellence in Shuttle Racking Layout Design: The Science Beyond the Schematic

A common misconception is that a shuttle racking layout design is simply about arranging aisles and racks on a floor plan. In reality, a superior shuttle racking layout design is a complex exercise in systems engineering. It requires the simultaneous optimization of multiple, often competing, variables: storage density, throughput velocity, equipment utilization, software logic, and long-term business growth.

A truly effective shuttle racking layout design must provide definitive answers to critical questions: How will stock-to-person picking interfaces be configured for minimal travel time? What is the optimal aisle configuration and depth to balance initial investment against long-term operational efficiency? How are buffer zones sized and positioned to ensure seamless integration with inbound receiving and outbound shipping areas, preventing system-wide congestion? How is the workflow of lifts synchronized with a fleet of shuttle cars to avoid becoming a critical bottleneck?

These solutions cannot be derived from a generic template; they demand a bespoke, data-intensive shuttle racking layout design analysis. A poorly conceived shuttle racking layout design inevitably leads to chronic inefficiencies: excessive shuttle vehicle empty travel, lift idle time, and a system throughput that falls dramatically short of projections. Therefore, investing in a meticulous, data-centric shuttle racking layout design process is the most crucial step toward ensuring project success.

The Pitfalls of Traditional Design Cycles and the Rationale for a 72-Hour Model

Historically, procuring a detailed shuttle racking layout design has been a slow, iterative process involving multiple vendor meetings, protracted data exchange, and weeks of waiting for a static, often hypothetical, PDF proposal. This conventional approach harbors significant drawbacks:

Decision Paralysis: Extended timelines delay entire project lifecycles, preventing businesses from rapidly adapting to market opportunities and eroding competitive edges.

The Comprehension Gap: Two-dimensional drawings and complex spreadsheets are difficult for non-technical stakeholders (e.g., CFOs, General Managers) to interpret, leading to high internal communication costs and delayed approvals.

Hidden Systemic Risks: Static proposals cannot dynamically demonstrate system performance under peak load conditions. Potential bottlenecks and conflicts remain hidden until after installation, at which point remediation costs are exorbitant.

It is precisely to address these industry-wide inefficiencies that leading storage solution providers have pioneered a revolutionary service: the delivery of an immersive 3D simulation and a definitive shuttle racking layout design within 72 hours. This is not merely an acceleration of pace; it is a fundamental transformation of the project initiation paradigm. It shifts the client from a passive recipient of information to an active participant in the design process, enabling a comprehensive, transparent evaluation of the future system’s performance before a major financial commitment is made.

The 72-Hour Process Deconstructed: The Methodology Behind High-Speed, High-Fidelity Shuttle Racking Layout Design

The viability of this service rests on three pillars: a standardized data intake protocol, powerful proprietary design and simulation software, and a dedicated team of seasoned engineers. The following section provides a detailed breakdown of each critical phase within the 72-hour window.

Phase 1 (0-24 Hours): Deep-Dive Data Integration and Strategic Alignment

The foundation of speed is precise input. The process commences with an efficient, collaborative workshop aimed not only at data collection but also at understanding the core logic of the client’s business.

Digital Twin of Physical Space: Acquisition of precise CAD drawings or detailed dimensions of the warehouse structure, including clear ceiling height, column grid locations and dimensions, floor flatness and load-bearing capacity, and the placement of fire suppression systems and doors.

Granular SKU Profile Analysis: The cornerstone of any intelligent shuttle racking layout design. This involves a detailed analysis of all SKUs: pallet specifications (dimensions, type, overhang), weight, special handling requirements (e.g., refrigeration), and crucially, an ABC classification based on turnover velocity. This analysis directly informs the slotting strategy within the shuttle racking layout design, positioning fast-moving goods for optimal accessibility.

Throughput Benchmarking: Defining the system’s key performance indicators (KPIs), such as the number of pallets to be stored and retrieved per hour/shift, order profile characteristics (full-pallet vs. case picking), and the intensity of peak-season fluctuations.

Operational Cadence and Future-Proofing: Understanding current shift patterns and anticipated business growth over a 3-5 year horizon. A robust shuttle racking layout design must incorporate scalability and flexibility from the outset.

By the conclusion of this phase, the design team has fully digitized the client’s operational landscape, setting the stage for computational modeling. A comprehensive shuttle racking layout design brief is formally established.

Phase 2 (24-48 Hours): Algorithmic Modeling and Multi-Scenario Optimization

This is the core technical phase. Engineers utilize the aggregated data within advanced simulation software to initiate an algorithm-driven shuttle racking layout design process.

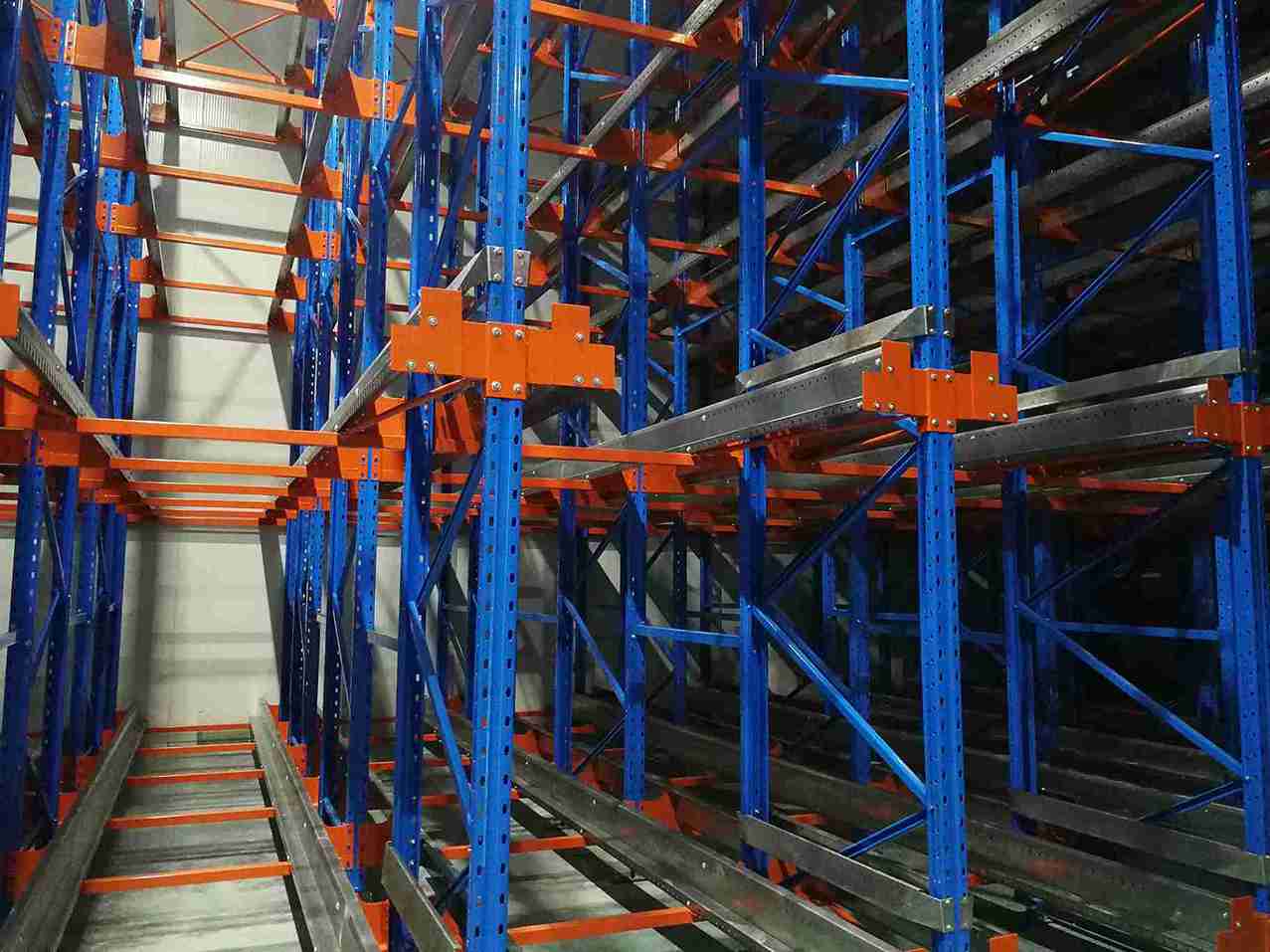

Parametric Modeling: The software enables the rapid generation of multiple, distinct shuttle racking layout design alternatives. Engineers can compare the density and efficiency trade-offs of single-deep versus double-deep storage, evaluate the impact of aisle width on vehicle velocity, and simulate the effect of adding a second or third lift on overall system throughput.

Multi-Objective Optimization: The software does not produce a single solution; it performs thousands of iterations based on predefined goals (e.g., “maximize storage density,” “maximize throughput,” or “minimize cost per pallet handle”) to generate a portfolio of candidate shuttle racking layout design options, each with distinct advantages.

Bottleneck Pre-Identification: Even at this stage, the software runs these virtual shuttle racking layout design scenarios, identifying potential congestion points and equipment starvation issues. The engineering team conducts a preliminary review, eliminating unviable options and shortlisting 2-3 high-potential shuttle racking layout design plans for in-depth analysis.

The deliverable from this phase is a set of data-rich, preliminary-validated shuttle racking layout design blueprints, each addressing the client’s core objectives from a different perspective.

Phase 3 (48-72 Hours): Immersive 3D Simulation Validation and Transparent Quotation Generation

This is the critical phase where data is transformed into insight, and blueprints are converted into confidence.

Creation of an Immersive 3D Simulation: The optimal shuttle racking layout design is selected and rendered into a high-fidelity, dynamic 3D virtual warehouse. This 3D simulation is far more than an animation; it is a functional digital twin that processes inputs and generates outputs. Clients can observe shuttle vehicles accelerating, decelerating, and storing/retrieving pallets, lifts operating in synchrony, and, most importantly, how the entire system performs under simulated daily or weekly workloads.

Comprehensive Performance Analytics: The 3D simulation generates a detailed performance report, including key metrics such as: theoretical maximum system throughput, individual equipment utilization rates (shuttles, lifts), identification of potential bottlenecks, and energy consumption estimates. This report provides irrefutable, data-backed validation for the proposed shuttle racking layout design.

Generation of a Transparent Free Quote: Concurrently, the sales engineering team produces a highly detailed free quote based on the final Bill of Materials (BOM) generated by the approved shuttle racking layout design. This quote provides a clear, line-item breakdown of all costs: structural racking, shuttle vehicles, lifts, warehouse control software (WCS), installation, and commissioning.

At the 72-hour mark, the client receives not a vague concept, but a validated shuttle racking layout design, an experiential 3D simulation, and a clear free quote. This package enables rapid, informed decision-making.

The Tangible Business Value of Investing in a Superior Shuttle Racking Layout Design

The return on investment from a world-class shuttle racking layout design extends far beyond its initial cost, delivering continuous value throughout the system’s lifecycle.

Maximized Spatial Utilization and Storage Density

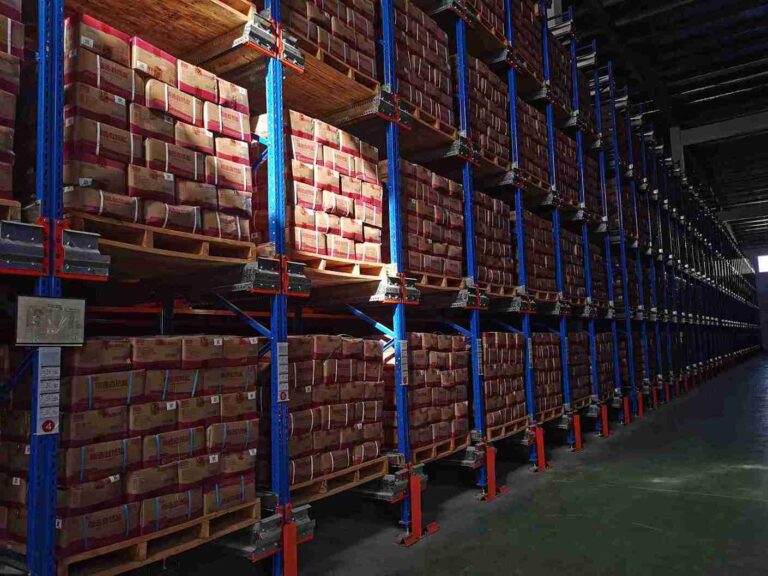

A precision-engineered shuttle racking layout design maximizes the use of available clear height and floor space, achieving exceptional storage density. Compared to traditional wide-aisle pallet racking, an optimized shuttle racking layout design can often increase storage capacity by 50% to over 100%, a critical factor in regions with high real estate costs.

Significantly Enhanced Operational Efficiency and Throughput

Throughput is the lifeblood of an automated system. A shuttle racking layout design rooted in flow analysis dramatically reduces average travel times for shuttles, optimizes the task sequencing for lifts, and thereby significantly boosts the overall inbound and outbound efficiency of the entire system. This translates directly into faster order fulfillment cycles and enhanced customer satisfaction.

Reduced Long-Term Operational and Maintenance Expenditure

A balanced and efficient shuttle racking layout design prevents the uneven wear that occurs when specific assets are over-utilized while others remain idle. This balanced load distribution reduces the mean time between failures (MTBF), lowering long-term maintenance costs and mitigating unplanned downtime risks.

Inherent System Flexibility and Scalability

Market conditions are dynamic. A proficient shuttle racking layout design incorporates scalability from the start. For example, the design can facilitate the future addition of shuttle vehicles or the easy extension of racking heights, making system expansion straightforward and cost-effective. This forward-looking approach is a hallmark of a professional shuttle racking layout design.

Ideal Candidates for a High-Speed, High-Precision Shuttle Racking Layout Design Service

This accelerated service model is particularly advantageous for businesses in rapid growth phases or those facing specific operational challenges.

Third-Party Logistics (3PL) Providers: Requiring rapid, customized solutions for diverse clients, the 72-hour shuttle racking layout design cycle enables them to respond to RFPs with unprecedented speed and confidence.

E-Commerce Fulfillment Centers: Facing extreme seasonal peaks, these operations need rapidly deployable, high-throughput systems. A shuttle racking layout design validated by 3D simulation ensures stability during critical sales events.

Cold Storage Warehouse Operators: With exceptionally high construction and operational costs, every cubic foot in a freezer is valuable. A meticulous shuttle racking layout design is paramount for maximizing ROI and minimizing energy consumption.

Manufacturing Central Warehouses: Supporting Just-In-Time (JIT) production requires ultra-reliable material supply. A robust shuttle racking layout design is fundamental to preventing production line stoppages.

The Technological Foundation: The Software Ecosystem Powering the 72-Hour Shuttle Racking Layout Design

This efficient process is underpinned by a suite of industry-leading software tools.

CAD/CAE Platforms: Used for precise structural design and engineering analysis, ensuring the shuttle racking layout design is inherently safe and compliant with all relevant standards.

Discrete Event Simulation (DES) Software: The core of the service. Applications like FlexSim, AnyLogic, or AutoMod simulate stochastic processes, testing the shuttle racking layout design under real-world conditions to prove its robustness before implementation.

Visualization and VR Tools: These technologies convert simulation data into photorealistic 3D visuals and even virtual reality experiences, allowing clients to “walk through” their future warehouse—a powerful tool for securing stakeholder buy-in.

Your Next Step: Initiating Your 72-Hour Shuttle Racking Layout Design Project

To activate this process and receive your custom shuttle racking layout design and free quote within 72 hours, preparing the following information will streamline the kickoff:

Architectural Site Drawings: CAD files (e.g., .dwg, .dxf) or detailed PDFs of the warehouse layout.

SKU and Pallet Master Data: An Excel spreadsheet detailing the dimensions, weight, and stack-ability for all pallet types.

Historical and Projected Operational Data: Past year’s inbound/outbound volume data, current inventory profile, and forecasted growth.

Primary Objectives: A clear statement of the key problems the new shuttle racking layout design should solve (e.g., increase capacity by 80%, handle 500 pallet moves per day, reduce labor dependency).

Conclusion: Transforming Uncertainty into Visualized Confidence, Accelerating Your Automation Journey

In warehouse automation, time is capital, and confidence is born from clarity. The traditional, protracted proposal cycle introduces unnecessary cost and uncertainty. The 72-hour custom shuttle racking layout design and 3D simulation service shatters this outdated model. It empowers decision-makers with直观的, credible business intelligence, enabling them to advance projects with speed and assurance. The shuttle racking layout design is the bedrock of a successful automation project, and now, you can secure this foundational blueprint without a multi-week wait. Contact a specialized warehouse automation partner today, provide your initial data, and start the countdown to a visualized, efficient, and profitable future.

Frequently Asked Questions (FAQs)

Q1: How accurate is the 3D simulation in predicting real-world equipment blocking and congestion?

The simulation is exceptionally accurate because it is based on discrete-event simulation (DES) technology, the industry standard for modeling complex dynamic systems. By inputting accurate operational data (order arrival times, vehicle velocities, transaction logic), the model replicates the stochastic nature of warehouse operations. It can predict equipment utilization rates, queue lengths, and potential blockage points with a typical accuracy of 95% or higher, allowing engineers to identify and resolve flow issues during the shuttle racking layout design phase, long before physical installation.

Q2: What is the process for making revisions to the initial 72-hour shuttle racking layout design, and are there associated costs?

We view the shuttle racking layout design process as collaborative. The 72-hour deliverable is a fully engineered, viable foundation. Minor adjustments based on client feedback (e.g., slight repositioning of a workstation, adjusting buffer sizes) are a normal part of the refinement process and are typically accommodated without additional cost. For significant scope changes (e.g., switching from a single-deep to a double-deep storage mode), we assess the impact and provide a revised proposal. Our goal is to ensure the final shuttle racking layout design is perfectly aligned with your operational needs.

Q3: What specific elements are included in the free quote provided with the shuttle racking layout design?

The free quote is a comprehensive, turnkey proposal based on the finalized shuttle racking layout design. It provides a transparent, line-item breakdown that typically includes: 1) All physical hardware (structural racking, shuttle vehicles, lifts, conveyors); 2) Essential software (Warehouse Control System – WCS); 3) Professional services (project management, installation, and commissioning); and 4) Training. Optional ongoing maintenance agreements are usually presented separately. There are no hidden fees.

Q4: Can your shuttle racking layout design process effectively handle challenging site conditions, such as irregularly shaped warehouses or facilities with numerous structural columns?

Absolutely. In fact, overcoming complex site constraints is a key differentiator of a expert shuttle racking layout design service. Our software tools import precise CAD drawings, and all obstructions like columns and irregular walls are modeled as fixed constraints. The algorithmic design process then optimizes the shuttle racking layout design around these parameters, often turning challenges into opportunities for innovative space utilization that a less sophisticated process would miss.

Q5: From a layout design perspective, what are the primary advantages of a shuttle system compared to a traditional ASRS mini-load or a stacker crane system?

This is a fundamental strategic question. While all are excellent ASRS solutions, their shuttle racking layout design philosophies differ significantly. The primary advantage of a shuttle system lies in its inherent scalability and parallel processing capability. The shuttle racking layout design consists of multiple independent aisles that can operate simultaneously, providing greater throughput elasticity and making future expansion (adding aisles) more straightforward and cost-effective. Stacker crane systems, while very fast, often have the aisle itself as a potential bottleneck.

The choice between technologies heavily depends on SKU characteristics, throughput requirements, and growth plans—factors that our 72-hour shuttle racking layout design and analysis process is specifically designed to clarify and validate for your unique operation.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com