📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

For decision-makers in the food and beverage sector, the cold storage warehouse is not merely a building; it is the pulsating heart of the supply chain, where profitability is preserved, and brand integrity is safeguarded. The relentless pressure to maximize storage density while ensuring flawless FIFO (First-In, First-Out) compliance in a high-cost, energy-intensive environment defines the daily operational battle. This definitive guide explores the advanced material handling solution that is revolutionizing food logistics: high-density shuttle racking for the food industry.

It delves into how this automated storage technology serves as a strategic imperative, directly addressing the most pressing FIFO challenges in cold storage facilities, driving down operational expenditure, and building a more resilient, profitable, and safe operation. The adoption of shuttle racking for the food industry is a calculated move beyond conventional storage, positioning businesses for sustainable growth.

H2: The Non-Negotiable Mandate of FIFO in shuttle racking for food industry

In many industries, inventory management is a function of accounting. In the food and beverage sector, it is a fundamental pillar of public safety and quality assurance. FIFO is the uncompromising standard.

H3: Food Safety, Compliance, and Brand Protection

The ramifications of an inadequate FIFO system are severe and far-reaching. When older stock is inadvertently buried behind newer arrivals, the risks escalate from financial loss to existential threat. Product spoilage leads to direct financial write-offs, but the greater danger lies in the potential distribution of expired goods. This can trigger catastrophic product recalls, erode decades of consumer trust in a brand overnight, and expose the company to significant legal liability.

Furthermore, global food safety standards like BRCGS, IFS, and SQF mandate verifiable FIFO processes. A failure to demonstrate robust control can result in failed audits and the loss of crucial contracts with major retailers. Implementing a failsafe system like shuttle racking for the food industry is a primary defense against these risks.

H3: The Amplified FIFO Challenge in Cold Storage Environments

While FIFO is complex in any warehouse, the cold storage environment intensifies every difficulty. The sub-zero conditions are inherently hostile to both human labor and machinery. Deploying personnel for extended periods to manually retrieve pallets from deep within racking lanes is not only inefficient but also raises serious worker safety concerns and leads to substantial energy loss each time a door is opened. Traditional high-density solutions like drive-in racking create deep lanes where pallets can become virtually inaccessible, making true FIFO management a logistical nightmare.

The exorbitant cost of constructing and operating cold storage—from refrigeration’s massive energy draw to the premium price of real estate—means that any inefficiency or wasted space directly impacts the bottom line. This makes the case for shuttle racking for the food industry particularly compelling.

H2: Deconstructing Shuttle Racking: A Paradigm Shift in Storage Technology

So, what is the solution engineered to meet these exacting demands? It requires a move beyond static storage into the realm of intelligent, dynamic automation. Shuttle racking for the food industry represents this evolutionary leap.

H3: The Core Components of an Automated Shuttle System

A high-density shuttle racking system is an integrated automated storage and retrieval solution (ASRS) comprising three synergistic components:

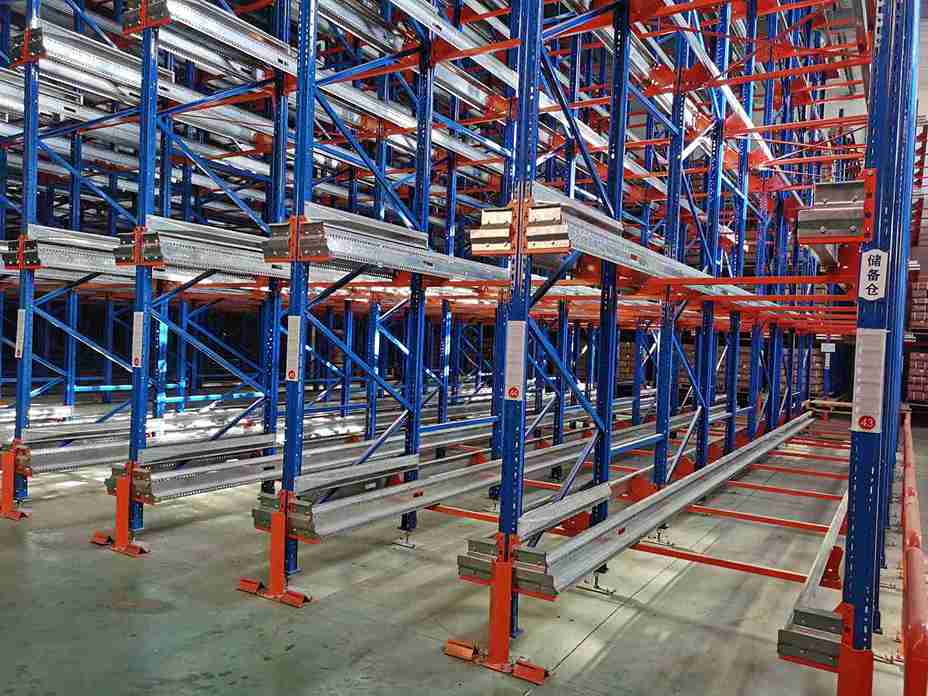

The High-Strength Racking Structure: This is not conventional pallet racking. It is a engineered structure consisting of multiple deep storage lanes, often holding dozens of pallets in depth, flanking a central picking aisle. Critically, the lanes are clear of obstructions, with no need for internal rails.

The Autonomous Shuttle Cart: This is a battery-powered, radio-controlled robot that operates within a single lane. It is designed to travel the length of the lane, lift a pallet, and transport it to the front for discharge or deep into the lane for storage. It is the tireless workhorse of the system, capable of operating in extreme cold.

The Intelligent Control Software: This is the brain of the entire operation. The software, which integrates seamlessly with a Warehouse Management System (WMS), dictates all movements. It commands the shuttle carts on precisely where to store and retrieve each pallet, maintaining perfect, real-time inventory control and enforcing strict FIFO or LIFO (Last-In, First-Out) logic as required. The sophistication of this software is what makes shuttle racking for the food industry so effective.

H3: Operational Workflow: A Symphony of Efficiency

The process is a model of engineered efficiency:

The Storage Sequence: A forklift operator places an incoming pallet at the entrance of a pre-assigned lane. With a simple command from a remote or terminal, the system is activated. A shuttle cart moves from its docking station, picks up the pallet, and transports it to the first available storage position deep within the lane. The forklift operator is free immediately, unlocking significant labor productivity.

The Retrieval Sequence: When an order requires a pallet, the WMS instructs the system to retrieve the next pallet in the FIFO sequence. The shuttle cart navigates to the exact location, retrieves the designated pallet, and delivers it to the lane entrance for pickup. This process is rapid, precise, and eliminates human error in stock selection. This operational elegance is the hallmark of modern shuttle racking for the food industry.

H2: The Strategic Synergy: Why Shuttle Racking is the Ideal FIFO Solution for Cold Storage

The true power of this technology is revealed in its application. Shuttle racking for the food industry is not merely an option; it is the optimal solution for cold storage challenges.

H3: Guaranteed, Software-Driven FIFO Compliance

The most significant advantage is the absolute elimination of FIFO human error. The system’s software logs a digital timestamp for every pallet stored. Upon order dispatch, it automatically commands the retrieval of the oldest pallet in the lane. This is FIFO perfection—mathematically precise, auditable, and automatically executed. For companies pursuing shuttle racking for the food industry, this provides an immutable digital trail that simplifies regulatory compliance and quality audits.

H3: Unparalleled Storage Density and Real Estate Optimization

By radically reducing the number of forklift aisles, high-density shuttle racking can increase storage capacity by over 80% compared to selective pallet racking. In the context of cold storage, where every square meter is astronomically expensive to build and refrigerate, this density translates into monumental cost savings. Businesses can store vastly more product within the same footprint or achieve their volumetric goals in a smaller, less capital-intensive facility. The reduced aisle volume also means a smaller air mass to cool, leading to sustained energy savings on refrigeration—a critical consideration for any operation implementing shuttle racking for the food industry.

H3: Revolutionizing Labor Efficiency and Enhancing Workplace Safety

Labor is a primary challenge and cost center in frozen environments. Automated shuttle systems drastically minimize the time personnel must spend inside the freezer. The role of the forklift operator evolves from a physically demanding and time-consuming search-and-retrieve mission to a streamlined pick-and-drop operation at the lane face. This dramatically improves worker safety and morale, reduces the risk of product and rack damage, and lowers costs associated with specialized protective equipment. The system operates continuously, unaffected by the harsh cold, making a commitment to shuttle racking for the food industry a commitment to a safer, more productive workforce.

H2: A Comparative Analysis: Shuttle Racking Versus Traditional Food Storage Methods

To fully appreciate the advancement shuttle racking for the food industry represents, a clear comparison with legacy systems is essential.

H3: Shuttle Racking vs. Drive-In/Drive-Through Racking

Drive-in systems have been a traditional method for achieving density. However, they suffer from inherent flaws. They require exceptionally skilled forklift drivers to navigate deep into the structure—a slow, hazardous, and costly process. FIFO is nearly impossible to maintain reliably, as lanes typically operate on a LIFO basis, leading to product spoilage. Damage to uprights and products is frequent. In contrast, shuttle racking for the food industry eliminates these risks, offering superior density, faster and safer operation, and guaranteed stock rotation.

H3: Shuttle Racking vs. Mobile Pallet Racking

Mobile racking also provides high density by moving entire sections of racking to create a temporary aisle. However, it still relies on manual forklift operation within that single aisle, which is slower than an automated shuttle retrieval. It also requires the forklift and operator to enter the cold environment. Shuttle racking for the food industry typically offers faster throughput, a higher degree of automation, and better labor efficiency, making it the superior choice for high-volume, temperature-controlled applications.

H2: Critical Implementation Considerations for a Shuttle Racking System

Deploying a high-density shuttle racking system is a significant capital project that demands meticulous planning and expert guidance. Success in implementing shuttle racking for the food industry hinges on several key factors.

H3: Comprehensive Site Assessment and Structural Integrity

A thorough evaluation of the existing facility is the non-negotiable first step. Structural engineers must assess floor flatness, load-bearing capacity, ceiling height, column spacing, and overall building integrity. The significant point loads imposed by a fully loaded shuttle racking for the food industry system require specific foundation specifications. A detailed site survey ensures the design optimizes material flow and integrates seamlessly with receiving, staging, and shipping areas.

H3: In-Depth SKU Analysis and Throughput Modeling

A successful deployment is predicated on a deep understanding of inventory characteristics. A detailed SKU (Stock Keeping Unit) analysis is conducted, examining the number of pallets, their dimensions, weight distribution, turnover velocity (ABC analysis), and seasonal demand fluctuations. This data is crucial for determining the optimal lane depth, configuration, and the number of shuttle carts required to meet peak throughput demands without creating system bottlenecks. This level of customization is central to an effective shuttle racking for the food industry solution.

H3: Seamless Integration with Warehouse Management Systems (WMS)

The intelligence of the shuttle system is fully realized through flawless integration with the host WMS. Bi-directional communication allows for real-time inventory updates, accurate order fulfillment, and centralized command and control. This interoperability is the key to transforming a standalone automation island into the integrated nerve center of the warehouse. Ensuring this seamless data flow is a critical step in any project involving shuttle racking for the food industry.

H2: The Future-Proof Warehouse: Integrating Shuttle Racking into Broader Automation

A shuttle racking system rarely exists in isolation. Its value multiplies when it becomes a core component of a connected, smart warehouse ecosystem. The future of shuttle racking for the food industry lies in its connectivity.

H3: The AGV/AMR Connection: Towards a “Lights-Out” Cold Store

The logical progression for maximizing automation is to integrate the shuttle system with Automated Guided Vehicles (AGVs) or Autonomous Mobile Robots (AMRs). In this scenario, the shuttle racking for the food industry handles the vertical storage and retrieval function, while the AGV manages the horizontal transport of pallets from the racking face to the shipping dock or workstations. This creates a truly “lights-out” (or minimally manned) cold storage facility, further reducing labor dependency, enhancing safety, and optimizing end-to-end material flow.

H3: Leveraging IoT and Data Analytics for Predictive Operations

Modern shuttle racking for the food industry systems are equipped with a multitude of sensors, making them rich sources of operational data. This Internet of Things (IoT) connectivity provides unparalleled visibility into system health and performance. Companies can monitor the status of each shuttle cart, predict maintenance needs before a failure occurs (predictive maintenance), and analyze storage patterns to continuously optimize lane assignments and inventory placement. This data-driven approach transforms the cold store from a cost center into a strategic, intelligent asset that drives continuous improvement.

H2: Conclusion: Building a Smarter, Safer, and More Profitable Food Warehouse

The challenges confronting modern food logistics—escalating costs, stringent safety protocols, and labor market constraints—are not abating; they are accelerating. Relying on outdated, manual storage methods is an increasing strategic vulnerability. The implementation of a high-density shuttle racking system is a proactive, strategic decision to future-proof an operation.

It is the definitive answer to the perennial FIFO challenges in cold storage, delivering an unparalleled combination of maximum spatial utilization, guaranteed product rotation, enhanced workplace safety, and a compelling return on investment. By embracing the automation inherent in shuttle racking for the food industry, businesses are not merely installing new racking; they are laying the foundation for a smarter, more resilient, and more profitable future.

H2: Frequently Asked Questions (FAQs)

H3: 1. Can a shuttle system handle mixed pallet sizes and weights within the same installation?

Yes, but this requires careful system design and configuration. Shuttle carts can be customized with adjustable forks or different carriage widths to accommodate various standard pallet types (e.g., Euro, GMA, block-type). The racking structure must be engineered to support the heaviest anticipated unit load. A detailed analysis of all pallet specifications during the planning phase is essential to ensure a shuttle racking for the food industry solution is perfectly tailored to handle product diversity.

H3: 2. What is the contingency plan if a shuttle cart experiences a mechanical failure?

System redundancy is a critical design feature for reliable shuttle racking for the food industry. Firstly, the shuttle carts themselves are built for high reliability and ease of maintenance. Secondly, most systems are designed with one or more reserve “satellite” shuttle carts. This spare cart can be quickly deployed to any lane in the event of a failure, ensuring that a single mechanical issue does not block access to inventory. The faulty unit can be swapped out and serviced without causing significant operational downtime.

H3: 3. How does the system perform in ultra-low temperature environments like blast freezers (-30°C / -22°F)?

Shuttle racking for the food industry is specifically engineered for harsh environments. The carts utilize special lubricants, components, and electronics rated for extreme cold, often as low as -30°C and beyond. Their batteries are thermally managed to maintain performance and charging efficiency in these conditions, with charging stations located within the cold environment to ensure operational continuity.

H3: 4. Is shuttle racking viable for facilities with lower clearances (e.g., under 10 meters)?

Absolutely. While the most dramatic density gains are achieved in high-bay warehouses (12 meters and higher), shuttle racking for the food industry provides significant benefits even in facilities with lower clearances (e.g., 6-9 meters). The density is achieved through the depth of the storage lanes rather than solely through height. The economic benefits of reduced aisle space and improved labor efficiency often yield a very attractive ROI even in lower-clearance buildings.

H3: 5. What is the typical operational lifespan of a shuttle racking system, and what are the maintenance requirements?

A well-maintained shuttle racking for the food industry system has an operational lifespan of 15 years or more. Maintenance requirements are predictable and manageable. They primarily involve regular checks and servicing of the shuttle carts, such as battery maintenance, wheel and bearing inspection, and software updates. Many providers offer remote monitoring and service contracts to maximize uptime. The robust design of the racking structure itself requires minimal maintenance, similar to conventional racking.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com