📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Paradigm Shift in Storage Optimization

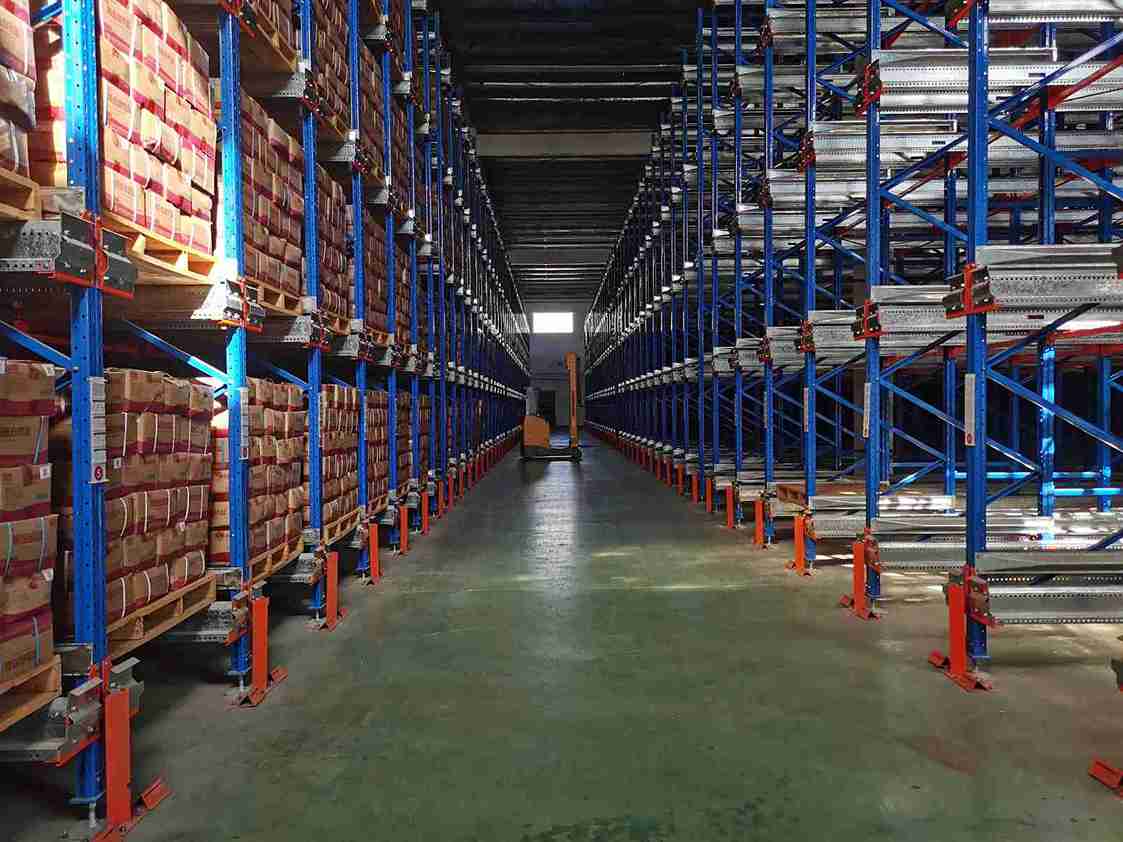

In the competitive landscape of modern logistics, the most strategic asset a company possesses is not just its inventory but the efficiency with which it utilizes its warehouse space. The central challenge—soaring operational costs against the constraints of finite physical space—demands a solution that transcends traditional storage methodologies. This comprehensive analysis delves into the transformative potential of automated storage systems, with a specific focus on the profound shuttle rack storage density benefits.

These systems are not merely an upgrade; they represent a fundamental re-engineering of warehouse architecture, enabling facilities to achieve unparalleled storage density increases of 80% and beyond within their existing footprints. The following sections will provide a granular examination of the mechanical principles, operational advantages, and financial imperatives that define these systems.

For logistics managers, warehouse operators, and corporate financial officers, understanding these benefits is crucial for strategic planning. The core thesis is unequivocal: maximizing density through automation is the most effective lever for reducing costs, enhancing accuracy, and future-proofing operations against market volatility and labor shortages.

The Inescapable Warehouse Crisis: Rising Costs and Static Space

The traditional response to inventory growth—expanding the warehouse’s physical footprint—has become a prohibitively expensive and often impractical strategy. The economics of commercial real estate, particularly in prime logistics corridors, have placed new construction and additional leasing out of reach for many businesses. Beyond the capital expenditure, this approach fails to address the inherent inefficiencies within the existing four walls. Conventional selective pallet racking, the industry standard for decades, is a paradigm of waste.

Its design necessitates a vast network of wide aisles to accommodate forklift navigation, effectively dedicating 40% to 50% of a facility’s total square footage to empty space. This layout creates a cascade of operational inefficiencies: extended travel paths for material handling equipment, inflated energy consumption for lighting and climate control in largely unoccupied areas, and an absolute cap on storage capacity. The financial implications are severe, eroding profit margins and limiting scalability.

It is within this context of spatial and economic pressure that the shuttle rack storage density benefits emerge as a critical solution. By fundamentally reconfiguring the storage model, these systems directly attack the root cause of inefficiency, turning wasted space into a valuable, revenue-generating asset.

Deconstructing the System: What is a Shuttle Rack?

A shuttle rack system is an automated, high-density storage solution that operates on a principle of decentralized, robotic movement. It replaces the traditional model of human-operated forklifts navigating wide aisles with a coordinated symphony of automated components. The system’s architecture consists of three integral elements:

The High-Density Storage Framework: This is the physical infrastructure, typically comprising multi-deep static racks or pallet live storage lanes. These lanes are deep channels designed to hold numerous pallets in a single file, one behind the other, maximizing the use of the building’s cubic volume from the floor to the ceiling.

The Autonomous Shuttle Carriers: These are battery-powered, robotic vehicles that operate on rails within the storage lanes. Each shuttle is an independent unit tasked with the horizontal movement of pallets, transporting them from the lane’s entry point to the next available storage position deep within the rack structure.

The Aisle-Lifting Interface: A vertical lift or a conveyor system stationed at the front of the storage block serves as the nexus between the automated world inside the racks and the external warehouse workflow. This component manages the vertical movement of pallets, delivering them to the correct level for the shuttle to receive or retrieve.

The operational genius of this configuration lies in its specialization of motion. The lift handles vertical travel, while the shuttle manages horizontal travel, allowing both to perform their tasks with maximum speed and precision, a core feature that delivers significant shuttle rack storage density benefits.

The Engineering of Efficiency: How 80%+ Density is Achieved

The claim of achieving over 80% storage density is a direct outcome of mechanical and spatial optimization, not theoretical speculation. The benefits are quantifiable and rooted in physics:

Near-Total Aisle Elimination: The most significant contributor to increased density is the radical reduction of aisle space. A traditional warehouse requires an aisle for every few rows of racking. A shuttle system consolidates this into a single, narrow access aisle for an entire storage block. This single change can reclaim over 90% of the area previously lost to forklift traffic, immediately converting it into profitable storage space.

Deep-Lane Utilization: Unlike a forklift, whose efficiency decreases the deeper it goes into a lane, a shuttle robot maintains consistent speed and performance regardless of lane depth. This allows for the design of extremely long lanes—20 pallets deep or more—fully leveraging the building’s length and width. This deep-lane configuration is a cornerstone of the system’s storage density capability.

Vertical Maximization (Cubic Space Utilization): Shuttle rack systems are engineered to exploit the full vertical height of a facility, often up to 45 feet or more. The combination of high-riseracking and the precision of the automated lift ensures that every cubic foot of available air space is used for storage, a feat impossible to achieve safely or efficiently with manual forklift operations.

The cumulative effect of these factors is a dramatic multiplication of storage capacity. A facility once holding 10,000 pallets might now hold over 18,000 without a single brick being laid. This is the ultimate manifestation of shuttle rack storage density benefits: doing more with less, and doing it smarter.

A Comparative Analysis: Shuttle Racks Versus Conventional Storage

To fully appreciate the shuttle rack storage density benefits, a side-by-side comparison with traditional storage methods is essential. The differences are not incremental; they are revolutionary.

| Feature | Traditional Selective Racking | Automated Shuttle Rack System |

|---|---|---|

| Storage Density | Low (40-50% space utilization) | Very High (80-90%+ space utilization) |

| Aisle Footprint | Multiple wide aisles required | Single, narrow access aisle |

| Labor Dependency | High (multiple forklift drivers) | Low (1 operator manages entire system) |

| Operational Speed | Variable, subject to human factors | Consistent, high, and predictable 24/7 |

| Inventory Accuracy | Prone to human error and misplacement | Near 100%; system-controlled via software |

| FIFO/LIFO Compliance | Manual, difficult to enforce perfectly | Perfect, automated compliance every time |

| Capital Investment | Lower upfront cost | Higher initial investment |

| Operational Expenditure | Higher long-term labor, energy, maintenance | Significantly lower operating costs over time |

| Scalability & Flexibility | Difficult to scale; requires more space | Easily scalable within the existing footprint |

| Safety & Damage | Higher risk of accidents and product damage | Enhanced safety; minimal product handling |

This table illustrates that the benefits of a shuttle rack system extend far beyond mere density, impacting nearly every aspect of warehouse operations, from financial performance to safety protocols.

The Ripple Effect: Operational Benefits Beyond Pure Density

While the dramatic increase in storage density is the most headline-grabbing feature, the most impactful shuttle rack storage density benefits are often the operational efficiencies that follow.

Unprecedented Labor Optimization: A single operator can oversee the entire storage and retrieval process for a massive block of inventory. The system’s software directs the lift and shuttles, while the human operator simply manages the transfer of pallets at the input/output point. This drastically reduces reliance on skilled forklift drivers—addressing a critical industry labor shortage—and reallocates human capital to more value-added tasks, improving overall productivity and job satisfaction.

Predictable, High-Velocity Throughput: Automated shuttles and lifts operate in a continuous, synchronized loop, unaffected by breaks, shift changes, or fatigue. They achieve exceptionally fast and consistent cycle times, dramatically accelerating both inbound and outbound logistics. This reliability is a game-changer for meeting tight shipping windows and managing high-volume, high-turnover inventory.

Flawless Inventory Integrity: In a shuttle rack system, the software is the absolute authority on inventory location. Every pallet is tracked from the moment it enters the system, eliminating the possibility of misplacement. This results in perfect inventory records, the virtual elimination of costly cycle counts, and guaranteed compliance with stock rotation protocols like FIFO, which is non-negotiable in sectors like food and pharmaceuticals.

A Safer, More Secure Environment: By removing forklifts from the dense storage area, the risk of accidents, collisions with racking, and product damage plummets. Pallets are handled with machine precision, not human variability. The storage block becomes a secure, automated environment, significantly enhancing workplace safety and reducing insurance liabilities.

Sustainability and Energy Efficiency: A smaller operational footprint means a substantially smaller volume of air to heat, cool, and illuminate. The shuttle rack storage density benefits thus include major reductions in energy consumption, lowering utility costs and contributing to corporate sustainability goals by reducing the warehouse’s carbon footprint.

Ideal Use Cases: Identifying the Right Fit for Shuttle Technology

The remarkable shuttle rack storage density benefits are most pronounced in specific operational contexts. These systems are particularly well-suited for:

High-Throughput Distribution Centers: Facilities managing a large volume of pallets with many SKUs experience the greatest gains in speed, accuracy, and space savings.

Space-Constrained Urban Logistics Hubs: For warehouses where physical expansion is impossible, maximizing cube utilization is the only viable path to growth, making the shuttle rack system an essential investment.

Cold Storage and Freezer Warehouses: The benefits are magnified in cold environments. Reducing the volume of refrigerated space and minimizing the time personnel must spend in sub-zero temperatures leads to enormous energy and labor savings, making the ROI exceptionally attractive.

Industries with Stringent Compliance Mandates: Businesses in food, beverage, and pharmaceuticals that require absolute FIFO control and perfect inventory traceability find that a shuttle system provides an automated, error-proof solution.

Operations Struggling with Labor Availability: Automating the most labor-intensive and repetitive tasks provides a strategic solution to the chronic shortage of qualified industrial劳动力, ensuring operational continuity.

Strategic Implementation: Key Considerations for System Design

Realizing the full spectrum of shuttle rack storage density benefits requires meticulous planning and customization. Several critical factors must be addressed during the design phase:

Load and Pallet Specifications: The system must be engineered for the specific dimensions, weight, and condition of the pallets and loads to be stored. Consistency is key to flawless automation.

Throughput Analysis: The required number of pallet movements per hour dictates the number of shuttles, the speed and capacity of the lifts, and the configuration of the pickup and delivery stations.

Software and Systems Integration: The intelligence of the operation lies in its software. The shuttle system’s control software must integrate seamlessly with the host Warehouse Management System (WMS) or Enterprise Resource Planning (ERP) system to ensure real-time, accurate inventory management and process control.

Structural Integrity and Floor Load Capacity: The immense weight of a densely packed shuttle rack system requires a professional structural analysis of the warehouse floor to ensure it can support the concentrated load without risk.

Future-Proofing for Growth: A well-designed system is modular and scalable. Planning for future expansion—such as adding more shuttles or extending lanes—ensures the investment continues to deliver benefits for years to come.

The Financial Rationale: Calculating a Compelling Return on Investment

While the upfront capital outlay for a shuttle rack system is significant, a thorough financial analysis focused on Total Cost of Ownership (TCO) reveals a compelling ROI. The shuttle rack storage density benefits translate directly into financial gains:

Capital Avoidance: The most substantial saving is often the avoided cost of constructing a new facility or leasing additional space. If a new warehouse costs millions, a shuttle system that doubles capacity for a fraction of that price represents an immediate capital saving.

Direct Labor Cost Reduction: The reduction in required forklift operators represents a significant and recurring annual saving on salaries, benefits, training, and insurance.

Operational Productivity Gains: The value of increased throughput, reduced order fulfillment times, and the elimination of inventory shrinkage contributes directly to higher customer satisfaction and revenue generation.

Indirect Cost Savings: Quantifiable reductions in energy bills, equipment maintenance (for fewer forklifts), and insurance premiums further accelerate the payback period.

A detailed ROI analysis typically reveals a payback period of 2 to 4 years, after which the system generates continuous operational savings and profit for the business.

The Implementation Roadmap: A Phased and Partner-Centric Approach

Achieving the promised shuttle rack storage density benefits hinges on a disciplined, phased implementation process managed by an experienced partner.

Deep-Dive Consultation and Data Mining: The process begins with a comprehensive analysis of current operations, SKU profiles, historical flow data, and future growth projections. This data-driven foundation is critical for a system designed for unique needs.

Simulation and Digital Twin Modeling: Advanced simulation software is used to create a digital twin of the proposed system. This model is used to test performance, identify potential bottlenecks, and optimize the design virtually before installation begins.

Site Preparation and Precision Installation: The project team manages all aspects of site readiness, including any necessary structural reinforcements, followed by the precise installation and calibration of all equipment.

Systems Integration and exhaustive Testing: The software is fully integrated with the client’s WMS/ERP, and the entire system undergoes rigorous testing to ensure it performs to specification under real-world conditions.

Comprehensive Training and Phased Go-Live: Key client personnel, from operators to maintenance staff, receive extensive training. A phased go-live plan ensures a smooth transition with minimal disruption to ongoing operations.

Long-Term Support and Continuous Improvement: A proactive service and maintenance agreement guarantees system uptime and performance, protecting the investment and ensuring the long-term realization of all shuttle rack storage density benefits.

Conclusion: Embracing Density as a Strategic Imperative

The evolution of the warehouse is no longer about moving boxes faster; it is about thinking smarter. In an era defined by spatial and economic constraints, the strategic imperative for logistics leaders is clear: maximize the potential of existing assets. The shuttle rack storage density benefits provide a proven, powerful pathway to achieving this goal. This technology transcends the category of material handling equipment; it is a comprehensive operational strategy that delivers unrivalled density, radical efficiency, and formidable competitive advantage.

By transforming static storage into a dynamic, intelligent asset, businesses can finally break free from the cycle of expansion and inefficiency. The decision to invest in a shuttle rack system is, fundamentally, a decision to future-proof the entire supply chain operation, securing its profitability and resilience for years to come. The benefits are too significant to ignore.

Frequently Asked Questions (FAQs)

1. How does a shuttle system handle different pallet sizes or weights in the same aisle?

Modern systems are designed for flexibility. Many shuttle models can be quickly changed over or are capable of handling a range of standard pallet sizes (e.g., EUR, CHEP). The system’s warehouse management software (WMS) is intelligent enough to assign pallets to appropriate lanes based on their dimensions and weight, ensuring optimal organization and safety without compromising the system’s overall storage density or performance. This flexibility is a key benefit for operations with diverse product lines.

2. What is the redundancy plan if a shuttle robot breaks down? Does the entire operation stop?

System design incorporates redundancy to mitigate this risk. For critical, high-throughput operations, multiple shuttles are deployed. If one unit requires maintenance, the others can continue operating, maintaining throughput at a slightly reduced capacity. Furthermore, most systems are designed with manual override options, allowing a forklift to service a lane in a worst-case scenario. This ensures that the shuttle rack storage density benefits are not sacrificed for reliability; the system maintains operational continuity.

3. Can shuttle systems be integrated with other automation like AMRs (Autonomous Mobile Robots) or conveyors?

Absolutely, and this is where the true potential of a automated warehouse is realized. A shuttle rack system acts as the high-density backbone of the warehouse. Its pickup and delivery (P&D) points can be seamlessly connected to a network of conveyors or served by a fleet of AMRs. This creates a fully integrated, “goods-to-person” workflow where the movement of inventory from receiving to storage to dispatch is entirely automated, maximizing efficiency and further amplifying the labor benefits of the initial investment.

4. Are shuttle systems only viable for massive corporations, or can mid-sized businesses benefit?

While early adopters were large enterprises, the technology has become more accessible and modular. The business case is often even more compelling for fast-growing mid-sized businesses that are acutely feeling the pressures of space and labor constraints. Suppliers now offer scalable solutions that allow a mid-sized company to implement a single shuttle aisle to address a specific bottleneck, with a clear roadmap for expansion as their business and needs grow. The shuttle rack storage density benefits are scalable across organization size.

5. Beyond pallets, can shuttle technology be applied to other storage media like bins or cartons?

Yes, the core technology principle is adaptable. While this article focuses on pallet shuttle systems, the same concept of autonomous robots moving within a dense storage structure is successfully applied to smaller loads. Mini-load shuttle systems are designed for storing and retrieving plastic totes or cartons, bringing the same density and efficiency benefits to piece-picking operations, order consolidation areas, and spare parts logistics. This demonstrates the versatility of the shuttle rack concept across the entire supply chain.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com