📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Definitive Guide to Mastering Warehouse Density with Shuttle Rack Technology

When logistics professionals and warehouse operators embark on a quest to solve their most pressing space and efficiency challenges, their search often culminates in a key phrase: shuttle rack for high density storage. This isn’t a casual inquiry; it’s a targeted search for a specific, high-impact solution. For companies like [Geelyracks], this search represents an opportunity to begin a transformative partnership. The decision to invest in a shuttle rack for high density storage is significant, requiring substantial capital expenditure and operational restructuring.

It demands not just a vendor, but a consultant and engineer. Recognizing this, [Geelyracks] extends beyond the standard sales pitch by offering a foundational service: a completely free, no-obligation warehouse layout design and quote, engineered from the ground up using real operational data.

This comprehensive resource is designed to be the final word on shuttle rack for high density storage systems, detailing their operation, their undeniable benefits, the critical considerations for implementation, and the unparalleled value of partnering with an expert who provides clarity and confidence from the first sketch to the final installation.

Deconstructing the Modern Shuttle Rack for High Density Storage: A Symphony of Engineering

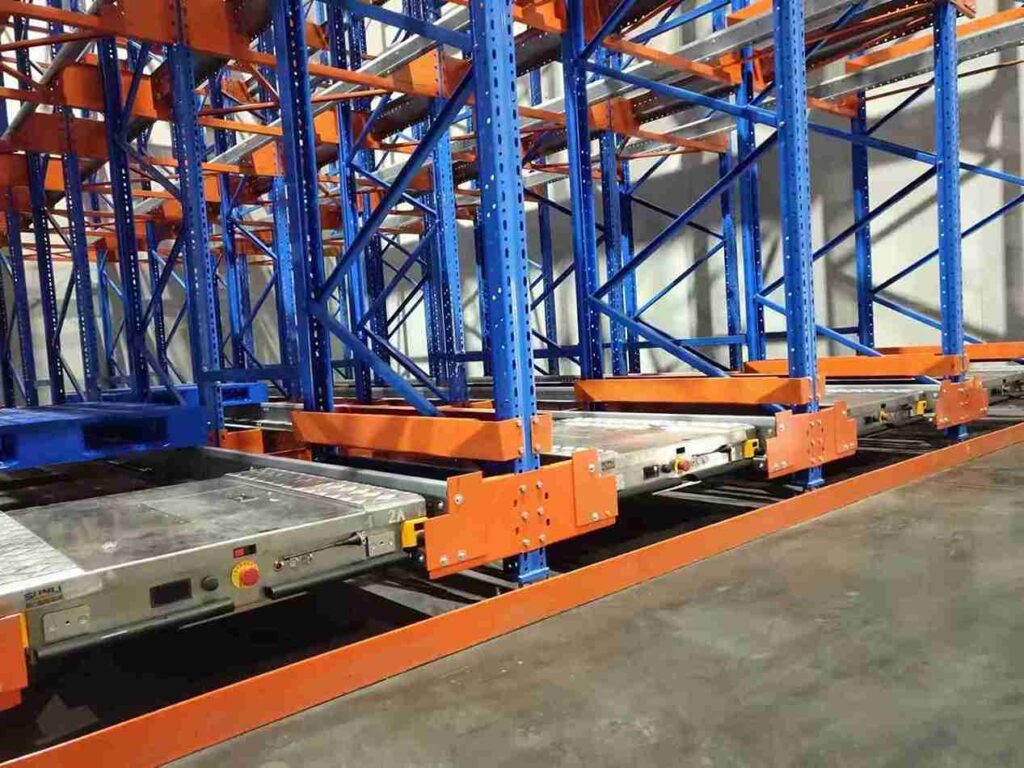

At its core, a shuttle rack for high density storage is an integrated system comprising a sturdy rack structure and autonomous, battery-powered shuttle vehicles that traverse the storage lanes. However, to label it merely as “racking” is a profound understatement. It is a precision-engineered ecosystem for material handling.

The defining characteristic of any shuttle rack for high density storage is its fundamental reimagining of the storage and retrieval process. In traditional systems, the forklift does all the work, navigating narrow aisles to place or retrieve each pallet individually. This is time-consuming, physically demanding, and poses significant safety risks. A shuttle rack for high density storage elegantly decouples these tasks. The forklift (or a stationary lift at the lane end) is elevated to the role of a high-speed transfer vehicle, interacting only at the lane’s entry point.

It deposits a pallet onto the waiting shuttle vehicle and, via a simple wireless command, instructs it to proceed. The shuttle then autonomously navigates the depth of the lane, precisely locating the next available storage position, gently depositing the pallet, and returning for its next instruction. This division of labor unlocks unprecedented levels of efficiency and density, making the shuttle rack for high density storage a cornerstone of modern intralogistics.

The Anatomical Blueprint of a High-Performance Shuttle Rack for High Density Storage

Understanding the quality and interplay of components within a shuttle rack for high density storage is critical for evaluating different suppliers. Not all systems are created equal, and the devil is in the engineering details.

The Racking Structure: The Backbone of the System: The supporting framework for a shuttle rack for high density storage is a world apart from standard pallet racking. It is a heavy-duty, meticulously engineered structure designed for immense loads and absolute precision. The rails upon which the shuttle travels must be perfectly level and aligned across the entire length of the lane; even a minor deviation can cause operational issues. The uprights, beams, and decking are calculated to handle not only the static weight of the stored goods but also the dynamic forces of the moving shuttle. The structural integrity of this framework is non-negotiable for the safe and reliable operation of the entire shuttle rack for high density storage system.

The Shuttle Vehicle: The Intelligent Workhorse: This is the technological heart of the operation. A high-caliber shuttle for a shuttle rack for high density storage is a marvel of mechatronics. It features high-torque motors capable of climbing the slight gradients of the racking, a sophisticated sensor suite for millimeter-precise positioning, and robust wireless communication modules. Modern shuttles utilize long-lasting, quick-swap lithium-ion battery packs, ensuring 24/7 operational readiness with minimal downtime. The software running on the shuttle dictates its intelligence, managing everything from battery life and error reporting to optimizing its travel path within the lane for the fastest cycle times.

The Control System: The Command Center: The interface through which humans command the machine. This can range from a simple, intuitive handheld remote control for the forklift operator to a fully integrated software platform that connects directly with the warehouse’s Warehouse Management System (WMS). In advanced implementations of a shuttle rack for high density storage, the WMS sends put-away and retrieval orders directly to the shuttle system, which then autonomously assigns tasks to the available shuttles, creating a truly “lights-out,” fully automated storage process. This level of integration is a key differentiator offered by leading providers.

The Compelling Case for Investment: Advantages of a Shuttle Rack for High Density Storage

The shift to a shuttle rack for high density storage is driven by a powerful roster of tangible benefits that directly enhance profitability and operational resilience.

Unrivaled Storage Density and Radical Space Savings

The primary and most celebrated advantage of a shuttle rack for high density storage is its ability to maximize every cubic foot of available space. By consolidating multiple pallet depths into a single, deep lane and eliminating the need for multiple forklift aisles, facilities can achieve an increase in storage capacity of up to 85% or more within the same building footprint. For companies facing exorbitant real estate costs, moratoriums on expansion, or simply looking to grow their inventory without relocating, the shuttle rack for high density storage presents the most effective and immediate solution.

A Quantum Leap in Productivity and Throughput

A shuttle rack for high density storage system fundamentally redefines labor efficiency. The forklift operator is no longer wasting precious minutes navigating long, dangerous aisles. Instead, they operate at the high-speed picking face, continuously loading and unloading shuttles. This parallel processing—where the forklift handles horizontal movement and the shuttle handles deep-lane vertical movement—can dramatically accelerate loading dock operations, reduce truck turnaround times, and allow a single operator to manage a vastly greater volume of pallets. The throughput gains are often the most immediately noticeable operational benefit after installing a shuttle rack for high density storage.

A Culture of Enhanced Safety and Risk Mitigation

Warehouses are inherently risky environments, with forklift-related incidents representing a significant portion of accidents. A shuttle rack for high density storage intrinsically promotes a safer workplace. It drastically reduces the need for forklifts to enter narrow, unstable aisles, thereby minimizing the risk of collisions with racking, product damage, and injuries to personnel. The shuttle operates in a confined, predictable path, removing the human element from the most hazardous part of the process. This safety improvement not only protects staff but can also lead to reductions in insurance premiums.

Pinpoint Inventory Control and Uncompromising FIFO/FILO Compliance

For industries where inventory rotation is critical, the shuttle rack for high density storage offers unparallelled control. The system’s software can be programmed to automatically enforce First-In, First-Out (FIFO) or First-In, Last-Out (FILO) logic with perfect accuracy. This is a game-changer for cold storage, food and beverage, pharmaceuticals, and any sector dealing with perishable goods or batch-controlled products. It eliminates human error in stock rotation, drastically reducing spoilage and ensuring regulatory compliance.

Significant Reduction in Long-Term Operational Expenditure

While the capital investment for a shuttle rack for high density storage is higher than traditional options, the total cost of ownership (TCO) often tells a different story. The labor savings are substantial, often allowing operations to achieve more with fewer personnel or reallocate staff to higher-value tasks. In cold storage and freezer applications, the dramatic reduction in open aisle space leads to massive energy savings, as less cold air escapes. Reduced product damage, lower equipment maintenance costs (less forklift wear and tear), and potential insurance savings all contribute to a compelling and often rapid Return on Investment (ROI), making the shuttle rack for high density storage a financially astute long-term decision.

Strategic Fit: Is a Shuttle Rack for High Density Storage Your Optimal Solution?

The shuttle rack for high density storage is a powerful tool, but it is not a universal fix. Its value is maximized under specific operational conditions. [Geelyracks]‘s consultancy process begins with a frank assessment of these factors to ensure strategic alignment.

Ideal Candidate Profile: The shuttle rack for high density storage shines brightest in environments with high-volume pallet movement, a high degree of pallet homogeneity (standardized sizes and weights), and a critical need for space consolidation. It is exceptionally well-suited for cold storage, food distribution, manufacturing buffer storage, and e-commerce fulfillment centers with deep inventory of fast-moving SKUs.

Operational Constraints to Consider: Operations with a vast number of very slow-moving SKUs or extreme heterogeneity in pallet sizes might not realize the full benefits. While multi-depth shuttles can handle some variation, significant inconsistency can complicate operations. The initial investment also requires a certain volume threshold to achieve a satisfactory ROI.

Comparative Analysis: Shuttle Rack for High Density Storage Versus Alternative Systems

A prudent decision requires a clear understanding of how the shuttle rack for high density storage compares to other high-density options.

Shuttle Rack vs. Drive-In/Drive-Thru Racking

Both systems offer high density, but the shuttle rack for high density storage is its technological successor. Drive-in racking requires forklifts to enter the structure, a process that is slow, hazardous, and notoriously damaging to both the racking and the forklifts themselves. The shuttle rack for high density storage eliminates this entirely, offering superior speed, safety, and product integrity.

Shuttle Rack vs. Mobile Pallet Racking (Moveable Aisles)

Mobile racking achieves density by moving entire rack sections to create a temporary aisle. While effective, this mechanical movement is slower than the retrieval speed of a shuttle rack for high density storage. Mobile systems are typically better suited for archival or lower-throughput environments, whereas the shuttle rack for high density storage is designed for dynamic, high-velocity operations.

Shuttle Rack vs. Fully Automated AS/RS (Automatic Storage and Retrieval Systems)

A shuttle rack for high density storage is often described as a semi-automated solution. A fully automated AS/RS, with its aisle-bound cranes and complete lack of human interaction, represents the peak of automation but also commands a premium price and requires specific building specifications. The shuttle rack for high density storage occupies a strategic middle ground, delivering a significant majority of the performance benefits of an ASRS—particularly in density and accuracy—with greater flexibility and a more accessible entry point, making it one of the most versatile solutions available.

The [Your Company Name] Difference: A Meticulous, Data-Driven Design Process

The offer of a free layout design is the cornerstone of [Geelyracks]‘s client engagement. It is a consultative, engineering-led process that transforms data into a bespoke operational blueprint.

Comprehensive Data Interrogation: The process begins with a deep analysis of the client’s operational data. This includes SKU profiles, pallet dimensions and weights, daily inbound/outbound volumes, seasonality patterns, and future growth projections. This data forms the immutable foundation upon which the entire shuttle rack for high density storage design is built.

Advanced 3D Modeling and Dynamic Simulation: Using state-of-the-art CAD and warehouse simulation software, engineers construct a digital twin of the proposed shuttle rack for high density storage system within the client’s exact facility dimensions. This model is then stress-tested using the client’s data to simulate weeks of operation in minutes, identifying potential bottlenecks in flow, throughput limitations, or equipment utilization issues before a single piece of steel is ordered.

Holistic Workflow and Ergonomics Integration: The design extends far beyond the racking itself. [Geelyracks]‘s experts model the entire material flow: from receiving docks and pallet staging areas, through the shuttle rack for high density storage system, and onward to the picking, packing, and shipping zones. This ensures the new system is not an isolated island of automation but a seamlessly integrated component of a optimized logistics pipeline.

Transparent ROI and Performance Projection: The final deliverable is more than a drawing; it’s a business case. Clients receive a detailed report projecting the key performance indicators of the new shuttle rack for high density storage: the exact storage capacity gain, the projected throughput increase, the labor and energy cost savings, and a clear, calculated timeline for Return on Investment. This empowers executives to make a confident, data-backed financial decision.

A Partnership for the Long Haul: Support, Training, and Continuous Optimization

The relationship with [Geelyracks] extends far beyond the installation day, ensuring the shuttle rack for high density storage continues to deliver value for years to come.

Certified Precision Installation: A perfectly designed system requires flawless execution. Certified installation teams ensure every component of the shuttle rack for high density storage is erected to exacting tolerances, guaranteeing optimal performance and safety.

Extensive Operator and Maintenance Training: [Geelyracks] provides comprehensive training programs for all stakeholders, from forklift operators learning the new workflow to maintenance technicians learning preventive maintenance routines. This knowledge transfer is crucial for long-term success and self-sufficiency.

Proactive Preventive Maintenance Programs: To safeguard the client’s investment, customizable service contracts are available. These programs schedule regular inspections and maintenance to ensure the shuttle rack for high density storage system operates at peak efficiency and to prevent unplanned downtime.

24/7 Expert Technical Support and Remote Diagnostics: Modern shuttle systems are equipped with telematics. This allows [Geelyracks]‘s support engineers to perform remote diagnostics, often identifying and resolving issues before the client is even aware of them, ensuring maximum uptime for the shuttle rack for high density storage.

Frequently Asked Questions (FAQs)

1. How does the system handle a situation where a shuttle’s battery depletes deep within a lane?

Modern shuttles in a shuttle rack for high density storage are equipped with sophisticated battery management systems that provide ample warning—often hours in advance—of a low battery. The system will typically alert the operator to retrieve the shuttle for a battery swap before it reaches a critical level. In the rare event a shuttle stops, its location is precisely known, and it can be manually retrieved using a special maintenance cart, ensuring no pallet is permanently trapped.

2. Can a shuttle rack system be retrofitted into an existing warehouse with a lower ceiling height?

Absolutely. While often associated with high-bay warehouses, one of the key advantages of a shuttle rack for high density storage is its flexibility. It can be designed to fit lower clear heights by optimizing the number of storage levels. The density gains are achieved in the horizontal plane by deepening the lanes, making it a viable solution for a wide range of building types, not just new, custom-built distribution centers.

3. What level of warehouse staff IT literacy is required to operate and manage the system?

The daily operation requires minimal IT skills. Forklift operators interact with a simple, menu-driven remote control. System management software, for monitoring performance and generating reports, is designed with intuitive user interfaces. Furthermore, comprehensive training is provided to ensure staff of all technical backgrounds are comfortable and confident in using the shuttle rack for high density storage system.

4. How does the system manage the storage of multiple SKUs within a single lane?

Best practice for a shuttle rack for high density storage is to store a single SKU per lane to maintain perfect inventory control and rotation. However, advanced warehouse management software can coordinate with the shuttle system to manage multiple SKUs in a lane if absolutely necessary, though this can add complexity. The initial design phase focuses on lane assignment to maximize efficiency and minimize this scenario.

5. What is the typical lifespan of a shuttle rack system, and how does the technology remain relevant over time?

The physical racking structure of a shuttle rack for high density storage has a lifespan of 20+ years with proper maintenance. The shuttle vehicles themselves, like any electro-mechanical device, have a shorter lifespan (typically 7-10 years) but are designed with forward and backward compatibility in mind. Software and control systems receive regular updates. The modular nature of the system means that as technology evolves, components can be upgraded or replaced without needing to dismantle the entire shuttle rack for high density storage, protecting the long-term investment.

Conclusion: Engineering a More Dense, Efficient, and Profitable Future

The journey to selecting and implementing a shuttle rack for high density storage is a strategic undertaking that redefines a company’s logistics capabilities. It is the definitive solution for businesses serious about conquering spatial constraints, accelerating operational throughput, and building a safer, more profitable warehouse environment. This technology represents not just an purchase of equipment, but an investment in a streamlined future.

The research phase is complete; the evidence is clear. The logical next step is to transition from general knowledge to specific application. [Geelyracks] invites you to move beyond speculation and see the precise impact a shuttle rack for high density storage could have on your bottom line. Claim your free, expert warehouse layout design and quote today. Engage with a partner whose process is built on engineering rigor, data transparency, and a commitment to your long-term success. Contact [Geelyracks] to initiate your consultation and embark on the path to a transformative warehouse optimization.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com