📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

For warehouse and operations managers, the constant battle between storage density and accessibility is a defining challenge. Traditional selective pallet racking offers excellent accessibility but wastes valuable space with numerous aisles. Drive-in systems maximize density but sacrifice selectivity and can create significant safety and product integrity concerns. The quest for a system that truly bridges this gap has led to the widespread adoption of Push-Back Racking Systems. This sophisticated, dynamic storage solution is engineered to deliver an unparalleled combination of high-density storage and exceptional selectivity, fundamentally transforming how modern warehouses utilize their cubic space.

We will delve into the intricate mechanics of push-back racking, exploring its core components, operational principles, and the tangible benefits it delivers. We will provide a detailed comparative analysis against other high-density systems, outline the critical considerations for successful implementation, and project the future trajectory of this vital technology. Our goal is to provide a comprehensive resource that empowers you to make an informed decision on whether push-back racking is the key to unlocking your warehouse’s full potential.

Understanding the Mechanics: How Push-Back Racking Works

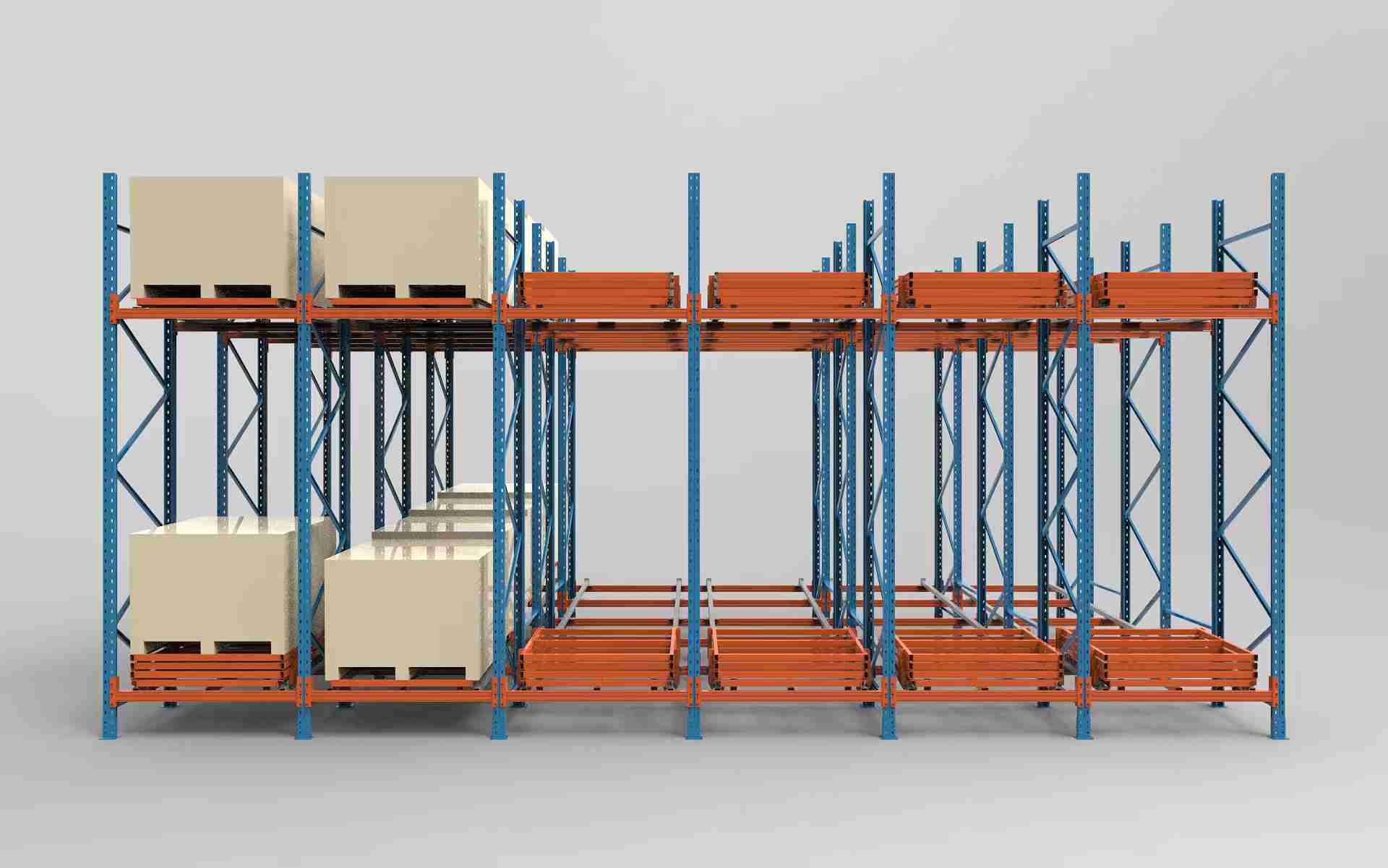

At its heart, a push-back racking system is an elegantly simple solution to a complex problem. It functions on the fundamental principle of Last-In, First-Out (LIFO) inventory management, but with a level of flexibility that pure LIFO systems often lack. The system is comprised of purpose-built inclined rail carts that are installed on multiple levels within a dedicated racking structure.

The process begins when a forklift operator deposits a pallet onto the first cart in a lane. The cart, which sits on a slight decline toward the aisle (typically around 5 degrees), is designed to roll backward upon receiving the weight of the pallet. As subsequent pallets are loaded, each new pallet gently pushes the existing row of pallets further back along the rails. This creates a dynamic, condensed storage lane where multiple pallets are stored in depth, yet each remains individually accessible.

When it’s time to retrieve product, the forklift simply extracts the first pallet in the lane. The absence of weight triggers the entire line of pallets behind it to gently gravity-roll forward, presenting the next pallet at the aisle face. This seamless, non-powered movement is the system’s greatest strength, eliminating the need for complex machinery, energy consumption, or manual labor to reposition loads. The entire operation is driven by gravity and precise engineering, ensuring reliability and speed.

Core Components of a Robust Push-Back System

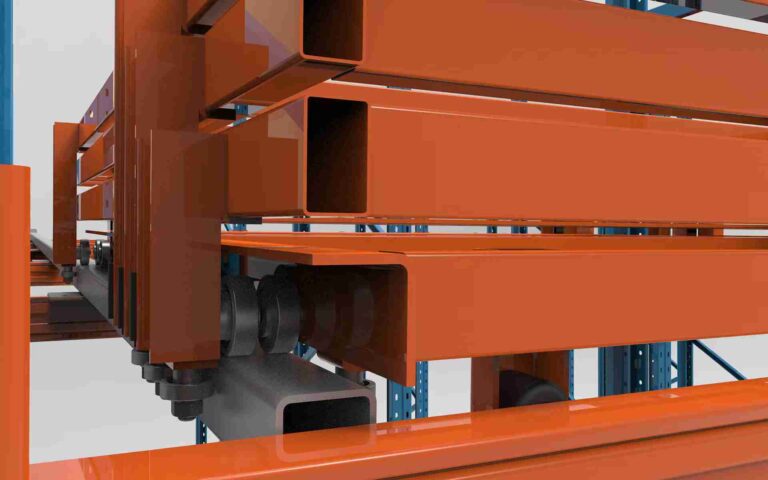

A reliable push-back racking installation is more than just sloped beams; it is an integrated system of specialized components, each playing a critical role in its performance and safety.

- •Structural Frames: These are the upright frames that provide the primary support for the entire system. They are typically heavier-duty than standard selective racking frames to handle the additional dynamic and static loads.

- •Inclined Beam Tracks: Unlike flat beams, push-back systems feature specially designed beams that serve as tracks for the carts. These are precision-engineered to maintain the correct angle of decline for optimal cart movement.

- •Nestable Carts or Carriers: The heart of the operation. These are wheeled carts that ride on the inclined beams. High-quality carts are constructed from durable steel and feature four independent, hardened steel wheels for smooth operation. They are designed to nest together when a lane is fully loaded, maximizing the usable depth.

- •Stopping & Safety Devices: To prevent carts from rolling out of the rack or colliding too forcefully, systems include end stops, lane dividers, and safety pins. These components are crucial for protecting both the inventory and the equipment.

- •Pallet Supports: These small ledges provide a stable resting point for the pallet on the cart, ensuring the load is secure and does not interfere with the cart’s movement.

The Unmatched Advantages of Implementing Push-Back Racking

Choosing a push-back system is a strategic investment that yields significant returns across several key operational metrics.

1. Dramatically Increased Storage Density: By storing pallets multiple deep (typically 2 to 5 pallets deep per lane, with some systems allowing even more), push-back racking can reduce aisle space by up to 75% compared to selective pallet racking. This allows you to store a vastly greater volume of product within the same warehouse footprint, directly translating to lower cost per pallet position and deferred capital expenditure on expensive warehouse expansion.

2. Enhanced Selectivity and Accessibility: This is the critical differentiator from other high-density systems like drive-in racking. While drive-in requires you to move other pallets to access a specific SKU, push-back racking offers true lane selectivity. Every single pallet stored in the system is accessible at the aisle face without needing to enter the lane or handle other products. This is a monumental advantage for operations with multiple SKUs per lane or those requiring reasonable FIFO turnover.

3. Improved Safety Profile: The design inherently promotes a safer working environment. Forklift operators only ever work from the safety of the main aisle, eliminating the need to navigate deep into narrow, confined racking structures. This drastically reduces the risk of accidental impacts with the racking, sprinkler heads, or other products. Furthermore, the gravity-powered movement removes the need for manual pushing or pulling of heavy loads.

4. Inventory Integrity and Flexibility: The gentle, rolling movement of the carts minimizes product shock and damage compared to systems where pallets are dragged or pushed across beams. The system also offers excellent flexibility; lanes can be configured to different depths within the same bay to accommodate varying product volumes or turnover rates.

5. Operational Efficiency and Cost-Effectiveness: With no need for complex automation, sensors, or power, push-back systems offer a high-density solution with minimal operational overhead. Maintenance is straightforward, typically involving simple inspections of carts and rails. The productivity gains from faster load/unload cycles further contribute to a lower total cost of ownership.

Push-Back Racking vs. Other High-Density Storage Solutions

To truly appreciate the value proposition of push-back racking, it must be viewed within the competitive landscape of high-density storage.

- •vs. Selective Pallet Racking: Selective racking offers 100% selectivity and excellent accessibility but at the cost of density. It requires an aisle for every single rack face. Push-back sacrifices perfect FIFO but gains 3-5x the density while maintaining very high accessibility.

- •vs. Drive-In/Drive-Thru Racking: Both drive-in and push-back are LIFO systems. However, drive-in requires the forklift to enter the rack structure, creating a significant safety hazard and requiring highly skilled operators. It also has very slow throughput times and high potential for product and rack damage. Push-back keeps the forklift in the aisle, is faster, and is far safer.

- •vs. Pallet Flow (Dynamic) Racking: Pallet flow is a high-density FIFO system using rollers and gravity. It is excellent for high-throughput, high-turnover, first-expiry-first-out (FEFO) applications like cold storage. However, it is generally more expensive than push-back due to its complex roller and brake systems and is less flexible for slower-moving goods. Push-back is often the more cost-effective choice for LIFO applications.

- •vs. Mobile Pallet Racking: Mobile racking offers the absolute highest density by eliminating all but one aisle through the movement of the entire rack structure. However, it is a high-capital-cost system with mechanical and electrical maintenance needs. Access is also slower, as aisles must be opened and closed. Push-back offers a simpler, more robust, and often more affordable high-density alternative.

Critical Considerations for a Successful Push-Back Racking Installation

Implementing a push-back system is not a one-size-fits-all endeavor. Several critical factors must be meticulously evaluated to ensure success.

1. Warehouse and Operational Audit: A thorough analysis of your facility is the non-negotiable first step. This includes precise measurements of clear ceiling height, floor flatness, and column locations. Operationally, you must analyze your inventory SKU profile, pallet specifications (size, weight, condition), and throughput requirements for each product.

2. Structural and Floor Requirements: The cumulative weight of multiple pallets on a single rail system places significant loads on the building’s structure and floor. A professional structural engineer must verify that your slab can support the point loads and that the building itself can handle the potential seismic and wind forces transmitted through the dense, heavy racking.

3. Forklift Equipment and Operator Training: Not all forklifts are created equal. Operating a push-back system requires a forklift with precise mast control and a level fork carriage to correctly deposit and retrieve loads from the carts. Operators must be trained on the specific loading and unloading techniques to ensure smooth operation and avoid damaging the carts or beams.

4. Lane Depth and Configuration Optimization: The ideal lane depth (2, 3, 4, or 5 pallets deep) is a calculated trade-off between density and selectivity. Deeper lanes mean higher density but reduce the number of available SKU faces. We help model your inventory to find the optimal configuration that balances these competing needs without compromising efficiency.

The Future of Push-Back Racking: Integration and Innovation

The evolution of push-back racking is not stagnant. As warehouse technology advances, push-back systems are increasingly being integrated into larger, automated ecosystems. We are now seeing the emergence of semi-automated systems where forklift operators are guided by warehouse management system (WMS) software, which directs them to specific lanes and confirms picks and puts. Furthermore, the components themselves are seeing innovation with advanced polymer coatings for smoother operation, enhanced safety interlocks, and designs that accommodate the evolving standard of pallet and product sizes.

The principles of push-back racking are also serving as a foundation for fully automated shuttle-based systems. These automated storage and retrieval systems (AS/RS) can be seen as the robotic, high-tech evolution of the gravity-powered push-back concept, offering even greater density and speed for the right application and budget.

Conclusion: Is Push-Back Racking the Right Solution for You?

Push-back racking systems represent a pinnacle of intelligent warehouse design, offering a powerful and practical solution to the eternal density-versus-accessibility dilemma. They are not a niche product but a mainstream, highly effective storage strategy for a vast range of industries, from food and beverage and retail distribution to manufacturing and cold storage.

If your operation manages a high volume of palletized goods with medium to high turnover rates, requires better density than selective racking can provide, but demands more flexibility and safety than drive-in racking offers, then a push-back system is almost certainly a perfect candidate for your facility. Its gravity-powered simplicity, robust design, and exceptional return on investment make it one of the most compelling choices in the material handling landscape.

The journey to maximizing your storage density and accessibility begins with a conversation with an experienced partner. We encourage you to reach out to our team of storage logistics experts for a comprehensive, no-obligation site survey and feasibility study. We will analyze your specific data, model potential configurations, and provide a detailed proposal that outlines the exact benefits a custom-engineered push-back racking system can deliver to your bottom line.

Frequently Asked Questions (FAQs)

1. What is the typical weight capacity for a push-back racking cart?

Weight capacities vary by manufacturer and specific cart design, but standard capacities typically range from 1,500 kg to 2,500 kg (3,300 lbs to 5,500 lbs) per cart. It is crucial to note that this is a per-cart capacity, and the entire lane’s structural design must be engineered to support the cumulative load of all pallets in the lane.

2. Can push-back racking be used for non-palletized loads or irregularly shaped items?

Generally, no. The system relies on stable, uniformly sized pallets to function correctly. Irregular loads or slip sheets may not sit properly on the cart, leading to jams, instability, or damage. Standard Euro pallets, CHEP pallets, and other standard-sized, stringer-class pallets are ideal.

3. How does the cost of push-back racking compare to other systems?

Push-back racking is more expensive per pallet position than selective pallet racking due to its specialized components. However, because it requires far fewer aisles, the total project cost for a given storage capacity is often very competitive. It is almost always more cost-effective than automated AS/RS and frequently offers a better return on investment than drive-in racking when operational efficiency and safety are factored in.

4. What kind of maintenance do push-back systems require?

Maintenance is minimal but essential. It primarily involves regular visual inspections of the carts for wheel wear or damage, checking that beams are clear of debris, and ensuring all safety stops and lane dividers are secure. Unlike motorized systems, there are no complex electrical or mechanical components to maintain.

5. Are there any specific fire safety considerations with push-back racking?

As with any high-density storage, push-back systems can present challenges for fire sprinkler systems. The dense storage can shield fire and prevent water from reaching the base of a fire. It is imperative to involve a fire safety engineer early in the design process. Solutions often include in-rack sprinkler heads specifically designed to mitigate the challenges of high-density storage environments.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com