📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

![Warehouse with pallet racking mezzanine installation by [Geelyracks]](https://geelyracks.com/wp-content/uploads/2025/08/Warehouse-with-pallet-racking-mezzanine-installation-by-Geelyracks.jpg)

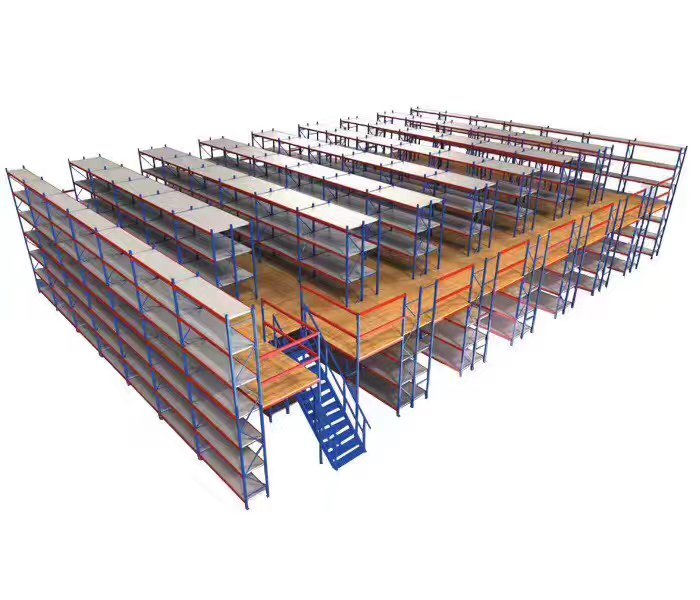

In the relentless pursuit of warehouse efficiency, the vertical space above your head represents your most significant, and often most underutilized, asset. At [Your Company Name], we specialize in transforming this empty air into a powerhouse of productivity and storage through the expert engineering and installation of custom pallet racking mezzanine systems. This isn’t just about adding a second floor; it’s about a fundamental reimagining of your operational workflow.

A well-integrated mezzanine doubles your storage capacity without the exorbitant costs of relocation or new construction, seamlessly blending with your existing pallet racking to create a cohesive, high-density storage solution. In this detailed guide, we will walk you through the critical engineering considerations, the integration process with automation like AGVs and forklifts, the undeniable return on investment, and why our commitment to a free, no-obligation layout design and quote is the essential first step in unlocking your warehouse’s true potential. We don’t just sell mezzanines; we deliver tailored, high-performance storage ecosystems built on decades of industry expertise.

![Warehouse with pallet racking mezzanine installation by [Geelyracks]](https://geelyracks.com/wp-content/uploads/2025/08/Warehouse-with-pallet-racking-mezzanine-installation-by-Geelyracks-1024x768.jpg)

Why a Pallet Racking Mezzanine is the Smartest Investment for Your Warehouse

Every square foot of your warehouse floor space is incredibly valuable. When it’s cluttered with inventory, workflow bottlenecks are inevitable, and efficiency plummets. Expanding outwards is often financially crippling, involving soaring real estate prices, lengthy construction projects, and business disruption. This is where the strategic genius of a racking mezzanine comes into play.

Think of it as a high-performance, structural deck that leverages the strength of your existing or new pallet racking to create a second or even third tier of operational space. You are not expanding your footprint; you are intensifying it. The immediate benefits are profound:

Maximize Cubic Space: Most warehouses use less than 25% of their available vertical space. A racking mezzanine allows you to utilize up to 95% of your air rights, effectively doubling your storage capacity within the same four walls.

Avoid Costly Expansion: The cost-per-square-foot of adding a pallet racking mezzanine is a fraction of the cost of building a new facility or leasing additional space. You invest in capacity, not in bricks, mortar, and land.

Improve Workflow Organization: By moving bulk storage or slower-moving inventory to the pallet racking mezzanine level, you free up precious ground-floor space for more value-added activities like picking, packing, cross-docking, and manufacturing, creating a more logical and efficient workflow.

Incredible Flexibility and Scalability: As your business evolves, so can your pallet racking mezzanine. Systems can be reconfigured, expanded, or even relocated to meet changing demands, protecting your investment long-term.

Beyond Storage: The Multifunctional Applications of a Pallet Racking Mezzanine Floor

While the primary function is often high-density storage, the versatility of a racking supported mezzanine is one of its greatest strengths. We have designed and installed systems that serve a multitude of purposes, proving that this solution is only limited by your imagination.

High-Density Storage Archive: The classic application. Ideal for storing seasonal items, archival records, or bulk raw materials that don’t require frequent access. A sturdy pallet racking mezzanine is perfect for creating this organized overhead archive.

Integrated Pick Modules: Create highly efficient multi-level order picking zones. By housing inventory on multiple levels of your pallet racking mezzanine, pick paths are shortened, and order fulfillment rates can skyrocket.

Office and Administrative Spaces: Build secure, quiet office spaces overlooking the warehouse floor, providing managers with a bird’s-eye view of operations without sacrificing valuable floor space. A pallet racking mezzanine can be insulated and finished to create a professional environment.

Production and Assembly Platforms: Relocate light assembly lines, quality control stations, or packaging operations to the pallet racking mezzanine level, effectively separating production from storage and logistics.

Equipment Mezzanines: House essential but space-consuming equipment like HVAC units, electrical panels, or compressors on a dedicated pallet racking mezzanine, keeping them accessible yet out of the way of main operations.

Employee Facilities: Create mezzanine-level break rooms, locker areas, or training rooms, fostering a better work environment without encroaching on operational areas.

The Critical Engineering Behind a Safe and Compliant Pallet Racking Mezzanine Design

At [Geelyracks], we never compromise on safety. A pallet racking mezzanine is a structural investment, and its integrity is paramount. Our design process is governed by rigorous international standards, including SEMA (Storage Equipment Manufacturers’ Association) guidelines and OSHA (Occupational Safety and Health Administration) regulations. Here’s what goes into ensuring your pallet racking mezzanine is not just functional, but fundamentally safe.

Structural Load Calculations: The Foundation of Safety for Your Mezzanine

The first question we answer is: what load does your pallet racking mezzanine need to bear? We calculate two primary types of loads:

Uniformly Distributed Load (UDL): This is the total safe operating load across the entire deck area of your pallet racking mezzanine, typically measured in pounds per square foot (psf). Standard industrial mezzanines we build can range from 150 psf for office space to over 300 psf for heavy palletized storage.

Point Loads: This refers to the concentrated weight of a single item on your pallet racking mezzanine, like the leg of a heavy piece of machinery or the wheels of a forklift. Our decking and beam systems are engineered to withstand these high point loads without deflection or failure.

Column and Beam Integrity: The Backbone of Your Pallet Racking Mezzanine System

The support structure, whether it’s integrated into your pallet racking or uses independent columns, is designed with a significant safety factor. We use high-grade, mill-certified steel and perform precise calculations for:

Vertical Load Capacity: Ensuring columns can support the combined dead load (weight of the structure) and live load (weight of stored inventory and equipment) for your pallet racking mezzanine.

Lateral Stability: Protecting the pallet racking mezzanine structure from sideways forces, such as those imposed by material handling equipment or seismic activity. This is achieved through strategic bracing and moment connections.

Decking Options: Choosing the Right Surface for Your Pallet Racking Mezzanine Application

The choice of decking is crucial for the safety, performance, and cost of your pallet racking mezzanine.

Heavy-Duty Steel Bar Grating: Provides excellent durability for your pallet racking mezzanine and allows light, air, and sprinkler water to pass through. Ideal for areas where debris fall-through is a concern.

Solid Steel Plate: Offers a completely solid surface for your pallet racking mezzanine, perfect for handling small parts and providing a smooth surface for equipment movement.

Plywood or Particle Board with Steel Support: A cost-effective option for light-duty pallet racking mezzanine applications or office spaces where a solid floor is needed for carpeting or tile.

Concrete Fill: Used on high-load pallet racking mezzanine applications, providing immense strength, vibration damping, and fire resistance.

Seamless Integration: Marrying Your Pallet Racking Mezzanine with AGVs and Forklifts

A modern warehouse is an automated ecosystem. Isolating your pallet racking mezzanine from this flow is a critical mistake. Our expertise lies in designing mezzanines that are fully integrated into your automated material handling systems, including AGVs (Automated Guided Vehicles) and unmanned forklifts.

Designing for Automated Access to Your Pallet Racking Mezzanine

Integration is planned from the very first CAD drawing. When designing a pallet racking mezzanine for automated access, our engineers consider:

AGV-Compatible Ramps and Aisles: We design ramps with precise inclines and declines that are navigable by your specific AGV models, ensuring smooth transitions between floors for your pallet racking mezzanine system. Aisle widths are calculated to allow for safe and efficient robotic turning and maneuvering on and around the pallet racking mezzanine.

Structural Considerations for Robotics: The pallet racking mezzanine structure must account for the consistent, repetitive loads and potential vibrations caused by continuous automated traffic, which differs from human-operated equipment.

Forklift Access: Lifts, Gates, and Safety Protocols for Your Mezzanine

For operations using traditional or unmanned forklifts, safe access to the pallet racking mezzanine is non-negotiable.

Integrated Freight Lifts and Elevators: For the safest and most efficient vertical movement of goods and even pallets to your pallet racking mezzanine, we can design and specify freight lifts that are structurally tied into the mezzanine. This is the gold standard for high-volume operations using a pallet racking mezzanine.

Gated Gates and Safety Barriers: Any opening in the pallet racking mezzanine deck must be protected by OSHA-compliant safety gates that prevent falls. We install heavy-duty gates that can withstand impact and are interlocked with equipment for maximum safety around your pallet racking mezzanine.

The Step-by-Step Process: From Your Initial Inquiry to Pallet Racking Mezzanine Project Completion

We believe in a transparent, collaborative process for building your pallet racking mezzanine. Understanding how we work will give you confidence in our partnership.

Initial Consultation & Needs Analysis: We start by listening. Our experts will discuss your pain points, capacity goals, workflow, and long-term plans for a potential pallet racking mezzanine.

On-Site Survey and Measurement: A critical step. Our engineers will visit your facility to take precise measurements, assess floor conditions, evaluate clear heights, and identify any potential obstacles for your pallet racking mezzanine installation.

Free Custom Layout Design & Quote: Using advanced CAD software, we create a detailed 3D model of your proposed pallet racking mezzanine system. This isn’t a generic drawing; it’s a tailored solution that shows exactly how the pallet racking mezzanine will fit and function in your space. This model forms the basis of your fixed, transparent quote.

Engineering Approval and Permitting: Once you approve the pallet racking mezzanine design, our engineering team finalizes all structural calculations and prepares any documentation required for local building permits.

Manufacturing: Your pallet racking mezzanine system is fabricated in our facility from high-quality materials, ensuring every component meets our strict standards.

Professional Installation: Our certified installation team arrives on schedule to assemble your pallet racking mezzanine with precision and efficiency, causing minimal disruption to your operations.

Final Inspection and Handover: We conduct a thorough safety inspection of your new pallet racking mezzanine with you, provide all necessary documentation and warranties, and ensure your team is comfortable with the new system.

Calculating the Unbeatable ROI of a Custom Pallet Racking Mezzanine

The investment in a pallet racking mezzanine is one of the highest-return decisions a warehouse manager can make. Let’s break down the numbers.

Cost of Inaction: Continue paying for external storage? Lease a new building? The annual costs of these alternatives are recurring and often increase year-over-year.

Cost of a Pallet Racking Mezzanine: A one-time capital investment. The cost per additional square foot gained from a pallet racking mezzanine is typically 60-80% less than the cost of acquiring new industrial space.

Efficiency Gains: The value of streamlined workflows, reduced picking times, and improved organization facilitated by the pallet racking mezzanine is immense, though harder to quantify. Often, the labor savings alone can justify the investment within a few years.

Increased Asset Value: You are physically adding a permanent, valuable asset to your facility in the form of a pallet racking mezzanine that increases its overall value and functionality.

Why Your Free Pallet Racking Mezzanine Layout Design is the Most Important Step

Anyone can sell you a pre-configured kit. The real value is in the design intelligence. Our offer of a free layout design and quote for your racking mezzanine is our commitment to proving our expertise before you spend a single dollar. This process provides you with:

A Clear Vision: The 3D model of your racking mezzanine makes the project tangible, allowing you to visualize the result and make informed decisions.

Accurate Pricing: Eliminates the risk of hidden costs or unforeseen complications with your racking mezzanine project later.

Validation of Concept: It proves that the racking mezzanine solution is feasible and tailored to your specific needs.

A Competitive Benchmark: It gives you a detailed, professional racking mezzanine design to compare against other vendors, ensuring you are comparing apples to apples.

Frequently Asked Questions (FAQs)

Q1: How long does it typically take to install a racking mezzanine?

A: The timeline varies significantly based on the size and complexity of the racking mezzanine project. A standard system can often be installed within 1-3 weeks by our professional team. The overall project timeline, from initial design to handover for a racking mezzanine, is typically 8-12 weeks, accounting for manufacturing and shipping.

Q2: Can a pallet racking mezzanine be relocated if we move to a new facility?

A: Absolutely. One of the key advantages of a structural racking mezzanine system is its flexibility. While it requires disassembly and reassembly by qualified professionals, the racking mezzanine can be moved to a new location, protecting your long-term investment. This is not typically possible with concrete expansions.

Q3: Do I need to reinforce my warehouse floor for a rack-supported racking mezzanine?

A: It depends. Part of our initial site survey for your racking mezzanine includes an assessment of your concrete slab’s thickness and psi strength. In many cases, the load is distributed effectively through the pallet racking footprint and does not require reinforcement. If necessary, we will identify this during the pallet racking mezzanine design phase and provide a solution.

Q4: What kind of maintenance does a steel racking mezzanine require?

A: Very little. The primary maintenance for your racking mezzanine involves periodic visual inspections for any damage from impacts and ensuring all bolts remain tight. We recommend an annual inspection of your pallet racking mezzanine by a qualified engineer to ensure ongoing safety and integrity, much like your existing pallet racking.

Q5: How does fire safety and sprinkler system integration work with a racking mezzanine?

A: This is a critical part of our racking mezzanine design. We work closely with your facility manager and local fire marshals to ensure compliance. The design for your racking mezzanine will ensure adequate clearance between the mezzanine deck and sprinkler heads. Often, we design the racking mezzanine system to incorporate new sprinkler lines on the mezzanine level itself, ensuring full coverage and meeting all NFPA (National Fire Protection Association) codes.

Conclusion: Elevate Your Operations, Not Just Your Inventory

The ceiling of your warehouse is not a limit; it is your next great opportunity. Investing in a custom-designed racking mezzanine from [Your Company Name] is a strategic decision that delivers immediate capacity, unparalleled efficiency gains, and a formidable return on investment. It is a solution engineered for the real world, integrating seamlessly with both manual and automated workflows while adhering to the highest possible safety standards. We invite you to take the first, no-obligation step toward unlocking this potential. Contact us today to schedule your on-site survey and receive your free, custom 3D layout design and quote for your new pallet racking mezzanine. Let’s build the future of your warehouse, together.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com