📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

In the rapidly evolving world of logistics and inventory management, the constant challenge is space. As businesses grow, inventory expands, but the physical footprint of a warehouse remains the same. The traditional solutions—building an expensive addition or relocating to a larger facility—are often capital-intensive, time-consuming, and operationally disruptive. However, a highly efficient and often underestimated solution lies not outward, but upward. Mezzanine Racking Systems represent a paradigm shift in warehouse optimization, enabling businesses to literally create new, multi-level storage space from thin air. This comprehensive guide delves into the engineering, strategic advantages, and transformative potential of mezzanine racking storage system solutions.

We will explore how they function as a cornerstone of high-density storage, their seamless integration with advanced automation like AGVs and pick-to-light systems, and the critical considerations for implementation. By leveraging the vertical cube of your existing facility, you can achieve unprecedented storage density, streamline workflows, and future-proof your operations without ever breaking ground on a new building. This is the ultimate strategy for maximizing your return on investment per square foot.

Table of Contents

The Unseen Asset: Your Warehouse’s Vertical Air Space

What Exactly is a Mezzanine Racking System? Beyond a Simple Platform

Engineering Excellence: The Structural Anatomy of a Mezzanine

Key Benefits of Implementing a Mezzanine Racking System

Capital Expenditure vs. Operational Expenditure: The Stunning ROI

Doubling or Tripling Storage Capacity Within the Same Footprint

Enhancing Operational Workflow and Pick-Path Efficiency

Is Your Warehouse a Candidate for a Mezzanine? Key Considerations

Clear Height and Building Structural Integrity

Floor Load Capacity and Column Placement

Designing for Purpose: Different Types of Mezzanine Applications

Bulk Storage Mezzanines for Palletized Goods

Modular Shelving and Carton Flow Systems on Mezzanine Decks

Creating Specialized Operational Zones: Offices, Pick Modules, and Production Areas

The Integration Powerhouse: Mezzanines and Warehouse Automation

Connecting Levels with Conveyor Systems and Spiral Lifts

AGV and Mobile Robot Integration in a Multi-Tier Environment

Implementing Pick-to-Light and Put-to-Light on Mezzanine Decks

The Installation Process: What to Expect from Survey to Handover

Safety First: Compliance, Guarding, and Load Management

Case Study: Transforming a 3PL’s Operation with a Multi-Tier Mezzanine

FAQs: Your Mezzanine Racking Questions Answered

Conclusion: Building Up—The Smartest Direction for Modern Warehousing

The Unseen Asset: Your Warehouse’s Vertical Air Space

Walk into any warehouse, and the immediate focus is on the floor—the aisles, the pallets, the bustling activity. But the most significant untapped resource is hovering right above it all: your vertical air space. Most warehouses are grossly underutilized in their vertical dimension, with precious cubic feet of potential storage space left empty. This “vertical cube” is an asset on your balance sheet that you haven’t yet activated. A mezzanine racking storage system is the key to unlocking this asset. It’s not merely an installation; it’s a strategic re-imagining of your facility’s volume. By building a second, or even third, level within your building, you are effectively constructing new floor space without the need for mortgages, construction permits, or moving trucks.

This approach transforms a sprawling, one-level operation into a concentrated, multi-tiered hub of efficiency, putting every possible cubic foot to work for your bottom line. The decision to invest in a mezzanine racking storage system is a decision to capitalize on an asset you already own but are not yet using.

What Exactly is a Mezzanine Racking System? Beyond a Simple Platform

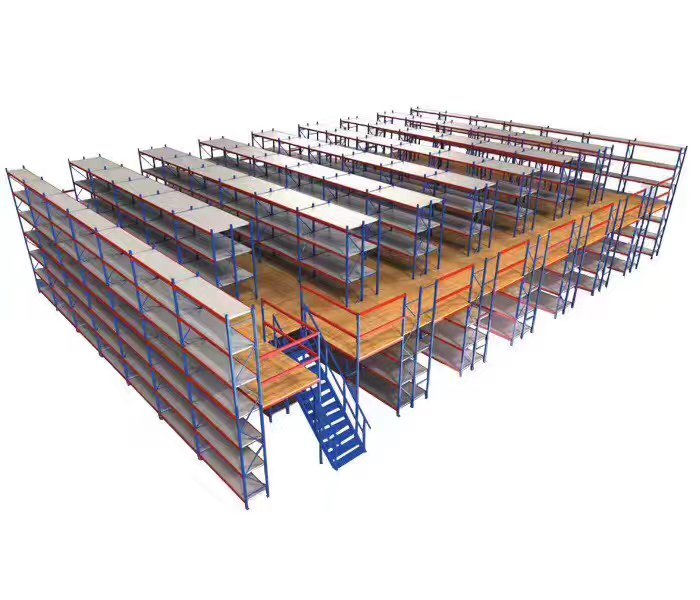

A common misconception is that a mezzanine is just a raised platform. While that’s the basic concept, an industrial mezzanine racking storage system is a complex, engineered structure that integrates seamlessly with your storage equipment. At its core, it is a freestanding or building-supported intermediate floor assembly installed between the main floors of a building. The structure typically consists of heavy-duty steel frames, decking (often robust steel grating or plywood), stairs, gates, and safety guarding. The true power, however, comes from what is placed on top of it. This is where the “racking” part becomes critical. The mezzanine deck is designed to support the immense weight of pallet racking, shelving, or carton flow systems, effectively creating a high-level storage aisle or an entire pick face.

It’s a symbiotic relationship: the mezzanine provides the new space, and the storage system organizes it for maximum utility. This combination is what defines a true mezzanine racking storage system—a holistic solution for vertical expansion. When professionals refer to a mezzanine racking storage system, they are speaking about this complete, integrated solution, not just the structural platform itself.

Engineering Excellence: The Structural Anatomy of a Mezzanine

The integrity of your entire operation depends on the strength and design of the mezzanine racking storage system structure. Understanding its components is crucial for any warehouse manager considering this powerful solution.

Primary and Secondary Beams: These are the backbone of the system. Primary beams span the main supports, while secondary beams provide the intermediate support for the decking. They are engineered to specific load capacities, ensuring the mezzanine racking storage system can handle the intended weight without deflection.

Upright Frames: These are the vertical columns that transfer the load of the entire mezzanine racking storage system, its contents, and personnel down to the warehouse floor. They are often adjustable for leveling, ensuring perfect stability on potentially uneven floors.

Decking Options: The choice of decking is vital for the functionality of the mezzanine racking storage system. Heavy-duty steel bar grating is common, offering durability and allowing light and sprinkler systems to penetrate. Plywood or steel plate decks provide a solid surface for smaller items and are often used for office spaces built within the mezzanine racking storage system.

Access Points: Industrial staircases, safety gates, and material lifts or conveyor systems are integral for safe and efficient access between levels of the mezzanine racking storage system.

Safety Systems: This includes full perimeter guarding, handrails, toe boards, and column protectors to prevent accidents and damage from equipment like forklifts. These are non-negotiable components of any certified mezzanine racking storage system.

Every component is calculated by structural engineers to comply with local building codes and OSHA regulations, ensuring the mezzanine racking storage system can handle the intended live load (storage and activity) and dead load (its own weight) with a significant safety factor.

Key Benefits of Implementing a Mezzanine Racking System

Capital Expenditure vs. Operational Expenditure: The Stunning ROI

The financial argument for a mezzanine racking storage system is overwhelmingly persuasive. Compared to the cost of relocating—which involves real estate fees, construction, moving inventory, and significant operational downtime—a mezzanine racking storage system is a fraction of the price. The investment is a clear capital expenditure that directly enhances the asset value of your current facility. The return on investment is calculated based on the cost per gained square foot. When you factor in the avoided costs of a move or new construction (which can run into millions), the ROI period for a mezzanine racking storage system is often astonishingly short, sometimes under two years. You are not just buying steel; you are buying affordable, highly efficient space. The financial logic behind a mezzanine racking storage system is clear: maximize the asset you have before incurring the massive debt of a new one.

Doubling or Tripling Storage Capacity Within the Same Footprint

This is the most tangible and celebrated benefit of a mezzanine racking storage system. By adding a single mezzanine level, you can effectively double your available storage space. Add a second tier, and you can triple it. This is high-density storage in its purest form. This new space isn’t just overhead; it’s fully functional floor space that can be configured with the same selective pallet racking, cantilever racks, or shelving as your main floor. It allows you to store more SKUs, handle higher inventory turns, and take on new client business without the panic of running out of room. It turns your warehouse from a constrained area into a scalable, multi-level environment. The capacity gains from a well-planned mezzanine racking storage system can be the difference between turning away new business and confidently expanding your market share.

Enhancing Operational Workflow and Pick-Path Efficiency

A mezzanine racking storage system does more than just add space; it can radically improve workflow and productivity. By strategically designing the mezzanine racking storage system, logistics managers can create dedicated zones for different activities, a concept known as activity profiling. For example, you can place your fastest-moving, high-turnover items on the ground floor for rapid access, and relegate slower-moving, bulk inventory to the mezzanine level. Furthermore, a well-designed pick module on a mezzanine racking storage system can dramatically shorten pick paths. Workers can pick along a continuous face on the mezzanine deck, using conveyors to send items down to the packing and shipping area, minimizing walking time and increasing picks per hour. The strategic implementation of a mezzanine racking storage system is therefore a dual-purpose investment: it solves the capacity crisis while simultaneously driving down operational costs through improved efficiency.

Is Your Warehouse a Candidate for a Mezzanine? Key Considerations

Clear Height and Building Structural Integrity

The single most important factor for installing a mezzanine racking storage system is your building’s clear ceiling height. You need ample space above the proposed mezzanine deck for clearance—not just for people to walk, but for sprinkler systems, lighting, and HVAC. A general rule of thumb is that you need a minimum of 15-18 feet of clear height to make a single-level mezzanine racking storage system viable. Secondly, while most mezzanines are designed to be freestanding (transferring load to the floor), your building’s columns and roof structure may still be assessed by an engineer to ensure the new mezzanine racking storage system doesn’t interfere and that the roof can support any potential additional load from tie-ins.

Floor Load Capacity and Column Placement

The warehouse floor must be able to support the concentrated point loads of the mezzanine racking storage system‘s upright frames. This often requires a core sample and analysis to determine the concrete’s psi (pounds per square inch) rating and thickness. The placement of existing columns, drainage grates, and other fixed infrastructure will also influence the optimal layout and design of the mezzanine racking storage system to maximize clear space below and above. A professional site survey is essential to map these obstacles and design a mezzanine racking storage system that works in harmony with the building’s existing features.

Designing for Purpose: Different Types of Mezzanine Applications

Bulk Storage Mezzanines for Palletized Goods

This is one of the most common applications for a heavy-duty mezzanine racking storage system. The mezzanine deck is engineered with a high live load capacity (e.g., 250 lbs/sq ft or more) to support multiple rows of pallet racking. Forklifts or stacker cranes access the mezzanine via a heavy-duty ramp or a specialized scissor lift for pallets. This application of a mezzanine racking storage system effectively creates a second-story warehouse within the warehouse, ideal for storing bulk pallets of seasonal goods, raw materials, or finished product inventory that doesn’t require frequent access.

Modular Shelving and Carton Flow Systems on Mezzanine Decks

For smaller parts, cartons, and SKUs, a mezzanine racking storage system is the perfect home for shelving or carton flow rack systems. This is ideal for e-commerce fulfillment centers and distributors of small parts. Workers can pick items from the flow racks on the mezzanine and place them on a take-away conveyor belt that runs directly to the packing stations, creating a highly efficient, continuous-flow order fulfillment system. This type of mezzanine racking storage system is often designed with a lower live load capacity but is optimized for human pickers and light-duty carton handling.

Creating Specialized Operational Zones: Offices, Pick Modules, and Production Areas

The versatility of a mezzanine racking storage system extends beyond pure storage. They are often used to create office spaces, quality control labs, or light assembly areas above the noisy production or storage floor. This frees up valuable ground-level space for more revenue-generating activities while providing a quiet, dedicated environment for administrative work. A mezzanine racking storage system used for this purpose might incorporate different decking materials, enhanced lighting, and HVAC systems to create a comfortable workspace, demonstrating the flexible nature of this storage solution.

The Integration Powerhouse: Mezzanines and Warehouse Automation

Connecting Levels with Conveyor Systems and Spiral Lifts

To truly maximize efficiency and justify the investment, the mezzanine racking storage system must be fully integrated into the facility’s material flow. Conveyor systems can be extended up to the mezzanine level via belt conveyors or spiral lifts, which gently transport cartons and totes between floors without manual intervention. This creates a seamless, continuous flow of goods from receiving, to storage, to picking, and finally to shipping. The integration of conveyors transforms a static mezzanine racking storage system into a dynamic part of the production line, moving goods efficiently and reducing manual handling.

AGV and Mobile Robot Integration in a Multi-Tier Environment

The rise of Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) presents a new frontier for the modern mezzanine racking storage system. While traditionally used on single levels, advanced logistics systems can incorporate robots that serve multiple floors. Goods can be delivered by robot to a lift mechanism, transported to the mezzanine level of the mezzanine racking storage system, and then another robot on that level can take over, moving them to their final storage location. This level of integration represents the future of automated storage and retrieval, where the mezzanine racking storage system acts as a multi-level highway for robotic fulfillment.

Implementing Pick-to-Light and Put-to-Light on Mezzanine Decks

Automation isn’t just about movement; it’s about information and accuracy. Pick-to-light and put-to-light systems are perfectly suited for mezzanine pick modules within a mezzanine racking storage system. These systems guide workers to the exact location and indicate the quantity to pick, drastically reducing errors and training time. When deployed on a mezzanine, they ensure that the efficiency gains of the vertical space are matched by the accuracy and speed of the picking process. Integrating this technology into a mezzanine racking storage system ensures that the expanded capacity does not come at the cost of accuracy or order fulfillment speed.

The Installation Process: What to Expect from Survey to Handover

A professional mezzanine racking storage system project follows a meticulous, multi-stage process designed to ensure safety, compliance, and minimal disruption. It begins with a detailed site survey by experienced engineers to measure clear heights, floor conditions, and obstacles. This is followed by the design and engineering phase, where the mezzanine racking storage system is customized to your specific needs, load requirements, and local building codes. Once approved, the components are fabricated off-site. Installation is typically performed by certified technicians and can often be completed with minimal disruption to ongoing operations, as the structure is bolted together. Finally, a full safety inspection and load testing ensure the mezzanine racking storage system is ready for handover and immediate use. Partnering with an experienced provider ensures this process is smooth and transparent from start to finish.

Safety First: Compliance, Guarding, and Load Management

Safety is the non-negotiable foundation of any industrial mezzanine racking storage system. The structure must be designed and installed to meet all applicable OSHA standards and local building codes. This includes proper guarding on all open sides, secure handrails, safety gates at stairways, and clear load rating placards. It is imperative that the stated live load capacity is never exceeded. Regular inspections, much like those for your pallet racking, should be conducted to check for any damage, corrosion, or deflection in the structure of the mezzanine racking storage system. Training staff on the safe use of the mezzanine, including weight limits and proper operation of gates and equipment, is a critical part of risk management. A safe mezzanine racking storage system is a productive one.

Case Study: Transforming a 3PL’s Operation with a Multi-Tier Mezzanine

Consider a real-world example that highlights the transformative power of a mezzanine racking storage system. A Third-Party Logistics (3PL) provider was bursting at the seams, facing a 40% growth in client orders but with zero room to expand their existing 50,000 sq. ft. facility. Moving was financially prohibitive and would cause catastrophic client disruption. The solution was a custom-designed, two-tier mezzanine racking storage system that added 20,000 sq. ft. of new storage space.

The lower mezzanine level was configured with carton flow racks for their highest-turnover e-commerce clients, feeding directly into a conveyor system. The upper level housed bulk pallet storage for slower-moving goods, accessed by a narrow aisle order picker. The result was a 40% increase in storage capacity, a 15% increase in pick rates due to optimized workflows, and the ability to comfortably onboard new business.

The mezzanine racking storage system project was completed in weeks, not the months or years a move would have required, and the investment was paid back in under 18 months through new revenue. This case demonstrates how a mezzanine racking storage system is not just a storage tool but a strategic growth engine.

FAQs: Your Mezzanine Racking Questions Answered

1. Can a mezzanine be relocated if we move to a new warehouse in the future?

Yes, one of the significant advantages of freestanding mezzanine racking storage system solutions is their modularity. They are designed to be disassembled and reinstalled in a new location. This protects your investment and adds a layer of long-term flexibility to your material handling assets, making the mezzanine racking storage system a reusable resource.

2. Do mezzanines require special fire protection or sprinkler systems?

Absolutely. Building codes require that the sprinkler system extends to all levels of the mezzanine racking storage system. A qualified installer will work with your fire protection provider to ensure the new deck is fully integrated into the existing sprinkler grid, maintaining compliance and safety. This is a critical step in the design of any mezzanine racking storage system.

3. How long does it typically take to install a medium-sized mezzanine system?

While design, engineering, and permitting can take a few weeks, the physical installation of a typical mezzanine racking storage system is surprisingly swift. For a system adding several thousand square feet, the on-site installation by a professional crew can often be completed within 1-2 weeks, minimizing operational downtime and allowing you to start utilizing the new space quickly.

4. Can mezzanines support the weight of heavy machinery like packaging equipment?

Yes, but this must be specified during the design phase. A mezzanine racking storage system can be engineered for very high live loads (300 lbs/sq ft or more) to accommodate heavy machinery, production equipment, or dense archival storage. The key is communicating this specific requirement to your supplier upfront so they can design the mezzanine racking storage system accordingly.

5. What is the difference between a structural mezzanine and a roll-formed or shelving-mezzanine?

A structural mezzanine racking storage system uses heavy, fabricated steel beams and columns designed to support high loads and large spans, making it suitable for pallet storage and heavy equipment. A roll-formed mezzanine is typically lighter duty, using lighter gauge steel and is often based on shelving uprights. It’s suitable for lighter storage and office applications but cannot support the same loads as a full structural mezzanine racking storage system. The right choice depends entirely on your intended application.

Conclusion

In the relentless pursuit of warehouse efficiency, the path of least resistance and highest return is not out, but up. Mezzanine racking storage system solutions are not a mere storage product; they are a strategic growth engine. They empower businesses to defy physical constraints, capitalize on their existing assets, and build a foundation for scalable, efficient, and automated operations. By thoughtfully designing a mezzanine racking storage system that integrates with your workflow and technology, you are not just adding square footage—you are architecting the future of your distribution center. In the modern supply chain, where agility and capacity are king, building upward with a robust mezzanine racking storage system is the smartest, most sustainable, and most profitable direction to grow. The question is no longer if you can afford to install a mezzanine racking storage system, but if you can afford not to.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com