📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Definitive Guide to Vertical Expansion

For logistics managers, warehouse operators, and business owners, the physical constraints of a building often present the single greatest barrier to scalability. When expansion outward is financially prohibitive and relocation is operationally catastrophic, the only logical direction for growth is upward. A custom mezzanine racking system represents the most sophisticated, efficient, and economically astute solution to this universal industrial challenge. This comprehensive resource delves into the intricate engineering, strategic planning, and transformative operational benefits of deploying a custom mezzanine racking system. It moves beyond basic explanations to provide a masterclass in how an intelligently designed mezzanine racking system integrates with existing storage infrastructure, supports advanced automation technologies, and delivers an unparalleled return on investment. This article will serve as an authoritative guide, demonstrating how a structural mezzanine racking system is not merely an installation but a fundamental reimagining of a facility’s storage potential, designed to propel businesses toward sustained growth without the monumental costs of traditional construction.

The Warehouse Capacity Crisis: Beyond Simple Clutter

The challenge is rarely a sudden event; it is a slow, creeping pressure that builds as a company succeeds. Inventory buffers grow larger to ensure supply chain resilience, SKU counts multiply to meet customer demand, and the once-spacious aisles of the warehouse become choked with pallets and products. Operators find themselves forced to make unacceptable trade-offs: turning away new business, leasing expensive and inefficient off-site storage, or sacrificing picking efficiency for mere storage density. The costs of these compromises are quantifiable: increased labor hours due to poor workflow, elevated safety risks from cluttered aisles, and missed revenue opportunities. The traditional solution—constructing a new building—involves a multi-million dollar capital outlay, a timeline stretching over a year, and a profound operational disruption. In this context, the custom mezzanine racking system emerges not just as an alternative, but as the superior strategic choice for intelligent capacity planning.

Deconstructing the Engineering Marvel: What is a Mezzanine Racking System?

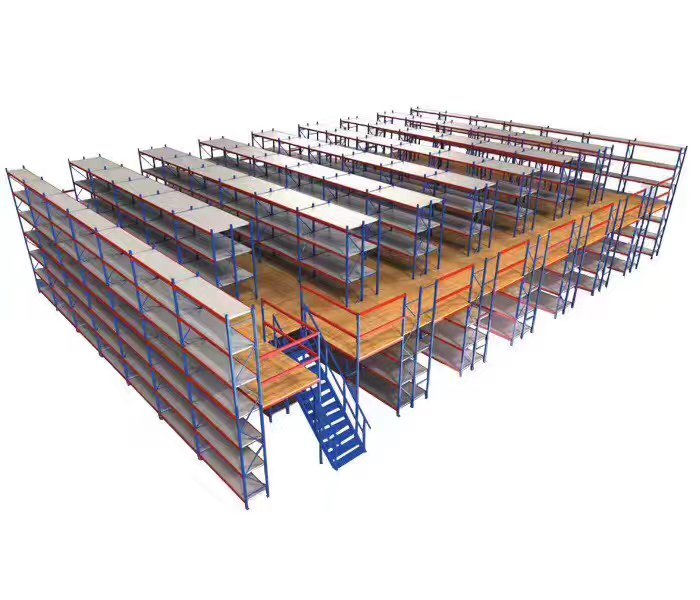

At its core, a mezzanine racking system is a multi-level structural platform that capitalizes on the unused vertical air space within a warehouse. However, to label it simply a “second floor” is to underestimate its complexity and capability. A true industrial-grade mezzanine racking system is a feat of precision engineering, comprising heavy-duty steel columns, deep-web primary beams, solid I-beam secondaries, and a decking system—often a combination of solid steel plate for heavy traffic areas and open bar grating for areas requiring ventilation and light penetration. The critical distinction of a racking mezzanine system is its symbiotic relationship with the storage equipment. The upright frames of the pallet racking are not just placed on the deck; they are often integral to the mezzanine’s support structure, creating a unified, ultra-strong storage fortress. This holistic design philosophy is what separates a high-performance custom mezzanine racking system from a generic storage platform.

The Blueprint for Success: Engineering Your Custom Mezzanine Racking System

The design process for a custom mezzanine racking system is a meticulous, collaborative endeavor between the client and the engineering team. It is a process rooted in data and driven by precision.

Phase One: Foundational Analysis and Load Calculation

The process initiates with a comprehensive site survey. Engineers measure the building’s clear height, column spacing, and floor flatness. They identify the location of critical infrastructure like sprinkler lines, electrical conduits, and lighting. The most crucial calculation involves determining the load requirements. The mezzanine racking system must be designed to handle two types of loads: the dead load (the immutable weight of the structure, decking, and permanently affixed racking) and the live load (the dynamic weight of inventory, personnel, and material handling equipment like walkie stackers and order pickers). For a racking mezzanine system supporting full pallets, live load designs often exceed 250 pounds per square foot (PSF), a testament to its industrial strength.

Phase Two: Strategic Integration with Storage and Automation

This is where vision becomes reality. The layout of the mezzanine racking system is dictated by the operational workflow. Will the upper level serve as reserve bulk storage, with products replenishing forward pick faces on the main floor via gravity feed conveyors? Or will it be a dedicated picking level for slow-moving SKUs, accessed by a narrow-aisle order picker? The design must accommodate these flows. Furthermore, the integration of automation is a key consideration. The structure must be engineered to support the vibration and load of conveyor systems, the precise tolerances required for an automated storage and retrieval system (AS/RS), or the installation of a vehicle lift for AGVs to transition between levels autonomously. Every aspect of the custom mezzanine racking system is planned for functionality.

Phase Three: Compliance, Safety, and Access Design

Safety is not a feature; it is the foundation of the design. The mezzanine racking system must comply with a myriad of codes, including the International Building Code (IBC) and OSHA regulations. This dictates everything from the height and strength of guardrail systems to the width and pitch of staircases. Egress planning is critical, ensuring multiple safe exit paths from the upper levels. The design also includes integration with the building’s fire suppression system, often requiring a dedicated sprinkler loop on the mezzanine level to ensure full coverage. The placement of access points—whether sturdy staircases, industrial-grade gates, or material lifts—is optimized to maintain workflow efficiency without compromising safety.

The Multifaceted ROI: Benefits That Extend Far Beyond Square Footage

While the primary driver for installing a mezzanine racking system is always additional space, the secondary benefits are often where the most significant value is realized.

Capital Expenditure Superiority: The financial argument is overwhelming. The cost per square foot of adding a mezzanine racking system is typically 50-70% less than the cost of constructing a new building or leasing additional space. This calculation does not even include the avoided costs of property taxes, insurance, and utilities on a separate facility.

Operational Resilience and Continuity: Construction on a new facility can halt operations for months. The installation of a prefabricated custom mezzanine racking system is a swift process that causes minimal disruption, allowing the business to continue functioning throughout the project timeline.

Process Optimization and Workflow Enhancement: A well-planned mezzanine racking system creates a vertical workflow. This segregation of processes—for example, housing long-term storage on the upper level and value-added services like kitting and packaging on the main floor—reduces congestion and streamlines material flow, drastically improving order fulfillment times.

Strategic Flexibility and Scalability: A business’s needs evolve. The modular, bolted design of a quality mezzanine racking system means it can be disassembled, reconfigured, or even relocated as requirements change. This protects the capital investment for the long term, making the mezzanine racking system a adaptable asset.

The Automated Mezzanine: Integrating Next-Generation Technology

The modern warehouse is a symphony of technology, and the mezzanine racking system is the stage upon which it performs. It is the ideal platform for deploying automation that maximizes density and speed.

Hosting Conveyor and Sortation Loops

In high-volume e-commerce fulfillment centers, the mezzanine racking system frequently serves as the backbone for complex material handling systems. Inbound goods are processed on the ground floor and then elevated to the mezzanine level. Here, they are inducted into a sophisticated network of conveyors that transport them to a put-to-light or pick-to-light station integrated directly into the racking on the mezzanine deck. After picking, items are conveyed to a sortation hub and then sent down to the packing and shipping stations below, creating a highly efficient, continuous-flow operation.

Enabling Robotic Mobility and AS/RS

For facilities utilizing Automated Guided Vehicles (AGVs) or Autonomous Mobile Robots (AMRs), the mezzanine racking system can be designed with integrated automated lifts or ramps. This allows the robotic fleet to access all levels of storage independently, creating a truly multi-tiered automated goods-to-person system. Furthermore, the robust structure of a racking mezzanine system can support the installation of unit-load AS/RS or mini-load systems on the upper level, transforming the entire volume of the building into a high-density, automated storage buffer.

A Foundation of Safety: The Non-Negotiable Principles of Mezzanine Design

The structural integrity and safety protocols of a mezzanine racking system are paramount. Every design decision is filtered through the lens of risk mitigation and regulatory compliance.

Professional Engineering Certification: Every single custom mezzanine racking system design must be stamped and certified by a licensed professional engineer. This ensures the structure is calculated to withstand all anticipated loads, including seismic and wind forces where applicable.

Comprehensive Fall Protection Systems: This includes not only standard guardrails and toe boards around the entire perimeter but also safety gates at the top of all staircases. These gates are designed to be self-closing and to withstand impact from equipment.

Fire Safety Integration: A major design consideration is the building’s fire sprinkler system. The installation of a mezzanine racking system will necessitate a redesign of the sprinkler layout to ensure adequate coverage both above and below the deck. This often involves installing a new sprinkler loop dedicated to the mezzanine level.

Adequate Lighting and Signage: The underside of the mezzanine and the upper deck itself must be equipped with dedicated, high-lumen lighting to eliminate shadows and dark spots that create safety hazards. Clear signage indicating load capacities, step hazards, and emergency exits is mandatory.

Quantifying the Advantage: A Detailed Return on Investment Analysis

Justifying the investment in a custom mezzanine racking system requires a clear-eyed financial analysis that goes beyond simple square footage cost comparisons.

Avoided Cost Analysis: The most straightforward calculation compares the total installed cost of the mezzanine racking system against the annualized cost of the next-best alternative. For example, if leasing off-site space costs $120,000 per year and the mezzanine project costs $400,000, the avoided cost pays for the system in just over three years, after which the savings drop directly to the bottom line.

Operational Efficiency Gains: The value of improved workflow must be quantified. If the new mezzanine racking system layout reduces picker travel time by 15%, that labor savings translates into thousands of dollars annually. Reduced product damage from better organization and fewer misplaced items also adds to the financial benefit.

Revenue Enablement: This is perhaps the most powerful argument. The new capacity provided by the mezzanine racking system allows the business to fulfill more orders, hold more inventory, and onboard new clients. The revenue from this new business, which would have been impossible before, directly offsets the project cost.

From Concept to Operation: A Real-World Implementation Story

Consider the case of a mid-sized pharmaceutical distributor operating from a 50,000 sq. ft. warehouse. Facing stringent FDA regulations requiring lot-level traceability and a 30% year-over-year sales growth, their existing layout was failing. Their solution was a custom mezzanine racking system that added 18,000 sq. ft. of critical space. The upper level was designed as a secure, climate-controlled environment with cantilever racking for bulky raw materials and selective pallet racking for finished goods. The main floor was reconfigured for value-added services, including a clean-room packaging area and a dedicated shipping lane. The mezzanine racking system was integrated with a wire-guided order picker for the upper level and a conveyor system for moving goods to packaging. The $750,000 investment was cash-flow positive within 18 months due to eliminated off-site leasing costs and a 22% increase in order throughput, a direct result of the optimized mezzanine racking system design.

Prerequisites and Considerations: Is a Mezzanine Racking System Your Solution?

While a powerful solution, a mezzanine racking system is not universally applicable. Key prerequisites must be met:

Sufficient Clear Height: The building must have ample vertical space. A minimum of 15-16 feet from finished floor to the lowest overhead obstacle (sprinkler lines, lights, ductwork) is typically required to create two functional levels.

Adequate Floor Strength: The existing concrete slab must be analyzed to ensure it can support the concentrated point loads from the mezzanine’s support columns without cracking or settling.

Long-Term Strategic Alignment: The decision to install a mezzanine racking system should align with the company’s long-term strategic plans for the facility, ensuring the investment will be utilized for years to come.

Conclusion: Building Your Growth on a Solid Foundation

The ceiling of a warehouse is not a boundary; it is the blueprint for its future capacity. In an era where logistics efficiency is a primary competitive advantage, the inability to scale operations within an existing footprint is a strategic vulnerability. A custom mezzanine racking system is the most potent tool available to warehouse operators for neutralizing this vulnerability and converting unused vertical space into a engine for growth, efficiency, and profitability. It is a testament to intelligent engineering and strategic planning, offering a flexible, high-return pathway to overcoming spatial constraints. For any business serious about scaling its operations without the exorbitant cost and disruption of relocation, the mandate is clear: look up, and engineer the solution that awaits.

Frequently Asked Questions (FAQs)

<h3>1. Can a mezzanine racking system be installed in a building with irregular column spacing or obstructions?</h3>

Yes, a significant advantage of a custom mezzanine racking system is its adaptability. Experienced engineers can design the structure to work around existing building columns, machinery, and other fixed obstructions. The design may involve creating specific clearances or using transfer beams to bridge over obstacles, ensuring the structural integrity of the mezzanine racking system is never compromised.

<h3>2. How does the installation process work, and how disruptive is it to daily operations?</h3>

The installation is methodical and planned to minimize disruption. The steel components are prefabricated off-site. The on-site installation follows a sequenced process: setting and anchoring support columns, installing primary and secondary beams, laying the decking, and finally installing guardrails and stairs. A professional crew can often work in designated zones, allowing other areas of the warehouse to remain operational. Communication with the installation team is key to scheduling the noisiest or most intrusive work during off-hours.

<h3>3. What are the different types of decking available for a mezzanine racking system, and how do I choose?</h3>

The choice of decking is critical for the functionality of the mezzanine racking system. The main options are:

Heavy-Duty Steel Plate: Used in high-traffic areas, especially where forklifts will operate. It provides a solid, durable surface.

Bar Grating: Offers excellent airflow, light transmission, and drainage. Ideal for areas where debris needs to fall through or where chemical storage requires ventilation.

Plywood or Particle Board with Laminate: A cost-effective option for light-duty office mezzanines or areas with only foot traffic. It is not suitable for an industrial racking mezzanine system.

The choice depends on the intended use, load requirements, and budget.

<h3>4. Are there any ongoing regulatory or insurance inspections required after installation?</h3>

Once the mezzanine racking system is signed off by the building inspector, there are typically no mandated annual regulatory inspections. However, it is considered a best practice and is often required by insurance providers to conduct an annual visual inspection of the structure. This inspection should check for any signs of damage, loose connections, corrosion, or overloading. This proactive maintenance ensures the long-term safety and integrity of the mezzanine racking system.

<h3>5. We have a high-bay warehouse. Can a multi-level mezzanine racking system be designed?</h3>

Absolutely. In facilities with very high clear ceilings (e.g., 30+ feet), a multi-tiered mezzanine racking system can be engineered to create three or even four operational levels. This design is exponentially more complex, requiring rigorous engineering analysis for load distribution, fire egress, and material handling between levels (often requiring dedicated lifts or conveyors). While a significant undertaking, a multi-level mezzanine racking system offers the highest possible density and return on investment in a suitable building.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com