📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The New Imperative for Modern Logistics

The landscape of global commerce has shifted irrevocably, placing unprecedented pressure on warehousing and distribution operations. The central challenge for today’s business leaders is no longer merely about storing goods; it is about transforming the warehouse from a cost center into a dynamic, intelligent engine for growth. This transformation is powered by the strategic deployment of a fully integrated warehouse automated storage system. Such a system represents the pinnacle of logistical engineering, a holistic solution that seamlessly combines high-density physical infrastructure with intelligent software and robotic mobility.

This comprehensive guide delves beyond the specifications of individual components to explore the strategic philosophy behind a successful warehouse automated storage system. It will illuminate how expert design and seamless integration can unlock unprecedented levels of space utilization, operational efficiency, and accuracy, delivering a formidable competitive advantage and a compelling return on investment for businesses ready to lead in their markets.

The Modern Distribution Center: A Paradigm Shift from Cost Center to Competitive Advantage

The traditional warehouse, reliant on manual labor, paper-based systems, and static storage, is an increasingly vulnerable link in the modern supply chain. It is plagued by escalating labor costs, chronic workforce shortages, and an inability to keep pace with the demands of e-commerce and omnichannel fulfillment. In this environment, errors in picking translate into costly returns, inventory inaccuracies lead to stockouts and overstock, and inefficient use of vertical space forces premature and expensive facility expansions. This operational model is no longer sustainable for companies that aim to lead their markets.

The evolution to an automated facility marks a fundamental paradigm shift. Implementing a sophisticated warehouse automated storage system is not merely an equipment upgrade; it is a strategic reimagining of the entire operational workflow. It involves creating a fluid, self-optimizing environment where data drives real-time decision-making, inventory is instantly accessible and 100% visible, and cubic space is utilized from the concrete floor to the ceiling trusses. This transformation is what turns a logistical liability into an undeniable strategic asset, enabling companies to promise—and deliver—what their competitors cannot.

Core Components of an Integrated Automated Warehouse System

The power of a modern warehouse automated storage system lies in the synergistic interplay of its core components. Each element is a technological marvel on its own, but its true potential is only unleashed through meticulous integration.

The Backbone: Automated Storage and Retrieval Systems (AS/RS)

At the heart of any high-performance warehouse automated storage system is the Automated Storage and Retrieval System (AS/RS). These computer-controlled systems are engineered for maximum density and speed, automatically placing and retrieving loads from precisely defined storage locations.

Unit-Load AS/RS: Designed for handling full pallet loads, these systems utilize tall, narrow-aisle racking structures served by dedicated stacker cranes. They are the workhorses for high-volume, high-density storage of goods with a lower SKU count, often in manufacturing or cold storage environments. The efficiency of a unit-load warehouse automated storage system is measured in its ability to minimize aisle space and maximize vertical footprint.

Mini-Load AS/RS: Engineered for storing and retrieving small parts, totes, and cases, a mini-load system is a cornerstone of e-commerce fulfillment centers. It uses a robotic shuttle to automatically bring entire storage bins directly to a picker at an ergonomic workstation. This “goods-to-person” principle dramatically reduces walking time, a significant waste in manual operations, and can increase pick rates by 300% or more, making it a critical component of a high-throughput warehouse automated storage system.

Vertical Lift Modules (VLMs) and Horizontal Carousels: These compact, high-density systems are the ultimate expression of the “goods-to-person” philosophy. VLMs consist of vertically arranged trays that shuttle items to an access point, while carousels rotate horizontally. Both are exceptionally space-efficient and are perfect for supporting value-added services like kitting or high-accuracy order picking in a minimal footprint.

The Muscle: Robotic Mobility and Transport (AGVs & AMRs)

While AS/RS handle the vertical movement within a warehouse automated storage system, Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) manage the intelligent horizontal flow of goods across the facility floor, connecting processes into a continuous flow.

AGVs (Automated Guided Vehicles): These reliable workhorses follow predefined paths, often using wires, magnets, or lasers embedded in the facility floor. They are exceptionally dependable for repetitive, point-to-point material transport tasks, such as moving loaded pallets from the receiving dock to the input point of the AS/RS. Their predictability makes them a stable force in a well-designed warehouse automated storage system.

AMRs (Autonomous Mobile Robots): Representing the next generation of mobility, AMRs use sophisticated onboard sensors, cameras, and laser mapping (LiDAR) to navigate dynamically through a facility. They can perceive their environment, avoid obstacles (including human workers), and choose the most efficient route to complete a task. This intelligence makes them incredibly flexible and easier to deploy and redeploy as operational needs change, adding a layer of adaptive intelligence to the warehouse automated storage system.

Unmanned Forklifts: These robotic forklifts are designed to perform all the tasks of traditional forklifts—lifting, moving, and stacking pallets—but with unerring precision and without a human operator. They integrate directly with the warehouse management system to execute tasks and can operate safely in collaborative environments, handling the heavy lifting within the warehouse automated storage system.

The Circulatory System: Conveyor and Sortation Systems

To create a seamless, continuous flow of goods from receiving to shipping, a robust network of conveyors and sorters is essential. This system acts as the circulatory system, connecting the various zones—storage, picking, packing, and shipping—and moving products efficiently between automated and manual processes. Modern high-speed sortation systems can use a variety of methods (pusher arms, cross-belts, tilting trays) to accurately divert thousands of items per hour to the correct shipping lane or packing station. The efficiency of this conveyance is a major determinant of the overall throughput of the entire warehouse automated storage system.

The Nervous System: Warehouse Control Software (WCS) and Execution Systems (WES)

If the physical components are the body of the operation, the software is its central nervous system and brain. This layer is the absolute critical linchpin of integration; without it, the most advanced hardware is merely a collection of disconnected machines. The intelligence of a warehouse automated storage system is embedded in its software.

Warehouse Control System (WCS): This software layer acts as a skilled translator and floor supervisor. It receives high-level orders from the Warehouse Management System (WMS) and translates them into detailed, real-time commands for the automated equipment. For instance, it directs a specific robot to retrieve a specific tote, commands a conveyor to route it to station #5, and instructs a printer to produce the correct shipping label—all in perfect synchrony.

Warehouse Execution System (WES): A WES represents a more advanced, holistic layer of intelligence that goes beyond simple control. A WES doesn’t just execute orders; it optimizes the entire workflow in real-time. It intelligently balances workloads across all resources (both human and robotic), prioritizes tasks based on dynamically changing deadlines (e.g., same-day shipments), and makes continuous decisions to maximize overall throughput and equipment utilization. It is the key to unlocking the full, synergistic potential of an integrated warehouse automated storage system, ensuring that all parts work together in perfect harmony toward a common goal.

The Expert Design Process: From Blueprint to Operational Reality

Deploying a sophisticated warehouse automated storage system is not a simple product sale; it is a deep, consultative partnership and a complex engineering undertaking. The process is meticulous, collaborative, and data-driven, ensuring the final solution is a perfect fit for unique operational and strategic goals.

Deep-Dive Discovery and Data Analysis: The foundation of a successful warehouse automated storage system is laid with comprehensive data. Experts immerse themselves in the client’s operations, analyzing current and forecasted SKU profiles, order volumes, peak season demands, and growth projections. Every process flow, from receiving to shipping, is meticulously mapped to identify bottlenecks, inefficiencies, and opportunities. This data-driven approach is the only way to architect a system designed for a client’s specific reality, not a generic off-the-shelf solution.

Conceptual Engineering and Simulation: Before a single rack is installed or a robot is deployed, engineers use advanced simulation software to create a digital twin of the proposed warehouse automated storage system. They run millions of virtual orders through this digital model to stress-test its design, identify potential congestion points, validate throughput capabilities, and fine-tune equipment utilization. This virtual prototyping de-risks the project immensely, allowing for optimization in a risk-free environment and providing a clear forecast of performance.

Phased Implementation and Integration: A detailed, phased project plan is developed to minimize disruption to ongoing operations. Implementation is carefully sequenced, often allowing parts of the warehouse to remain fully functional while new automated sections are brought online. Simultaneously, integration specialists work to seamlessly connect the new warehouse automated storage system with the client’s existing Enterprise Resource Planning (ERP) and Warehouse Management System (WMS) platforms, ensuring a unified flow of information.

Comprehensive Training and Ongoing Support: Empowering the client’s team is crucial for long-term success. Providers offer extensive training for maintenance and operational staff to ensure confidence and ownership of the new warehouse automated storage system. The partnership doesn’t end at go-live; leading providers offer ongoing support, remote monitoring, and performance optimization services to ensure the system continues to deliver peak performance and adapt to evolving needs for years to come.

Quantifiable Benefits: Measuring the Return on Your Automation Investment

The capital investment in an integrated warehouse automated storage system is significant, but the returns are transformative, measurable, and impact the entire organization.

Space Utilization Increased by up to 85%: By building upward with narrow-aisle or AS/RS solutions, businesses can often double or triple their storage capacity within the same existing square footage. This defers multi-million dollar capital expenditures on new building construction or allows for the reallocation of existing space to value-added services.

Labor Productivity Skyrockets: By eliminating non-value-added travel and implementing goods-to-person technologies, pick rates can increase from 100-200 picks per hour to 500-800 picks per hour or more. This allows companies to handle immense volume growth without a linear increase in labor costs and provides a powerful shield against the challenges of labor shortages.

99.99%+ Order Accuracy: Automation drastically reduces human error in picking and placing. This leads to a dramatic reduction in costly mis-ships, returns, and inventory reconciliation problems. The enhanced accuracy directly boosts customer satisfaction and strengthens brand reputation.

Enhanced Safety and Ergonomics: Automating the movement of heavy pallets and repetitive, strain-inducing tasks creates a significantly safer work environment. Employees are upskilled to more rewarding, higher-value roles such as managing, overseeing, and maintaining the technology, leading to higher job satisfaction.

Unparalleled Scalability and Future-Proofing: A well-designed warehouse automated storage system is inherently modular. As business grows or changes, the system can be expanded with additional storage modules, robots, or software upgrades. This modularity protects the long-term investment and ensures the operation is never a bottleneck to growth.

Is Your Operation a Candidate for Automation? Key Indicators

While every business is unique, several strong signals indicate a high and rapid return on investment from a warehouse automated storage system:

Labor Challenges: You are consistently facing difficulties in recruiting, training, and retaining reliable warehouse labor, or are overspending on seasonal temporary labor.

Space Constraints: You are planning to expand product lines or are experiencing rapid sales growth that your current facility cannot handle, and available vertical space is significantly underutilized.

Accuracy Issues: Your order accuracy rates are consistently below 99.5%, leading to high costs for returns, corrections, and customer dissatisfaction.

Throughput Limitations: Your current order throughput is limited by manual processes, creating delays in fulfillment and an inability to meet customer promises for fast shipping.

Rising Operational Costs: Labor, real estate, and error-related costs are eating into profit margins, and process inefficiencies are becoming a barrier to profitability.

Conclusion: Building the Intelligent Foundation for Future Growth

The journey toward implementing a fully integrated warehouse automated storage system is a strategic decision that transcends a simple operational upgrade. It is a fundamental reengineering of a business’s logistical core and a powerful commitment to future growth. It is an investment in predictability, scalability, and resilience. In an unpredictable market, the ability to fulfill orders faster, more accurately, and more efficiently than the competition is the ultimate advantage.

This transformation is not about replacing human ingenuity but about augmenting it with powerful technology, freeing talented teams to focus on strategy, exception management, and continuous improvement. By partnering with an expert provider that emphasizes holistic, expert design and flawless integration, business leaders are not just installing equipment; they are building a robust, agile, and intelligent ecosystem designed to drive profitability and power growth for the next decade and beyond. A well-executed warehouse automated storage system is the bedrock upon which market leadership is built.

Frequently Asked Questions (FAQs)

1. How does the maintenance regime for an automated system differ from maintaining traditional material handling equipment?

The maintenance paradigm shifts fundamentally from reactive to proactive and predictive. While traditional equipment might be maintained on a schedule or run until it fails, a sophisticated warehouse automated storage system is supported by sophisticated monitoring software that continuously tracks component wear, performance metrics, and error logs. This enables predictive maintenance, where issues are identified and resolved during planned downtime, which is far more efficient and less disruptive than emergency repairs. While the maintenance requires technically trained staff, providers offer comprehensive training and support contracts to ensure optimal long-term system health.

2. Can a warehouse automated storage system be integrated with our existing legacy Warehouse Management System (WMS)?

In the vast majority of cases, yes. A key component of the system’s design is the Warehouse Control System (WCS), which is specifically engineered to act as a middleware layer or translator. It seamlessly takes the high-level instructions from your existing WMS (e.g., “release this order” or “cycle count aisle B”) and translates them into the low-level, real-time commands that the automated equipment (robots, conveyors, sorters) can execute. Providers have extensive experience integrating with all major WMS platforms.

3. What level of facility infrastructure upgrade is typically required to support a warehouse automated storage system?

This is a critical consideration. Most high-level automation systems, particularly those involving AS/RS and robotics, have specific requirements. These often include reinforced flooring to handle concentrated dynamic loads, precise leveling of the floor surface for smooth robot operation, and potentially enhanced power distribution and data communication infrastructure throughout the facility. A thorough site survey is always conducted during the initial design phase to identify and plan for these requirements.

4. How does an automated system handle returns and reverse logistics, which are often highly variable processes?

Reverse logistics is a complex area, but an automated warehouse automated storage system can handle it efficiently. Typically, returned items are received at a dedicated inspection station. Once an item is inspected, graded, and decisions are made (restock, refurbish, discard), the system takes over. The WMS/WES will determine the appropriate storage location—which could be a dynamic location within the AS/RS for fast-moving restocked items or a designated area for quality control—and the automated systems will transport and store the item accordingly, ensuring it re-enters the inventory system accurately and is available for future sale if applicable.

5. We have a mix of very slow-moving and very fast-moving SKUs. How does the system optimize storage for such a diverse profile?

This is a key strength of an intelligent warehouse automated storage system. The Warehouse Execution System (WES) uses sophisticated algorithms based on ABC analysis and other logic. Fast-moving “A” items are dynamically assigned to storage locations that minimize retrieval times (e.g., at the front of an aisle or closer to packing stations). Slow-moving “C” items can be stored in higher-density, slightly less accessible locations. The system can continuously analyze picking patterns and automatically reassign storage slots to optimize the flow, ensuring the system’s performance adapts to changing demand patterns.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com

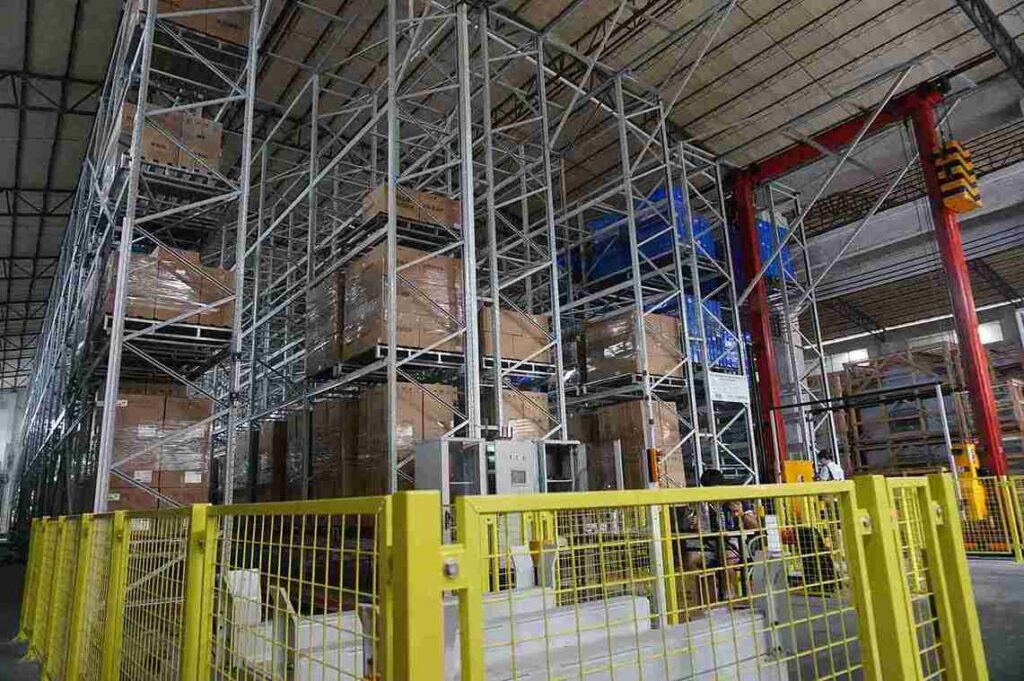

![High-density [automated storage racking system] for pallet storage – 80% space savings](https://geelyracks.com/wp-content/uploads/2025/08/High-density-automated-storage-racking-system-for-pallet-storage-–-80-space-savings-1-768x576.jpg)