📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Critical Role of Shuttle Racking in Today’s Supply Chain

In an era where warehouse efficiency directly impacts profitability, the shuttle racking system has emerged as a transformative solution for businesses seeking to optimize their storage operations. With its unique blend of automation and high-density storage capabilities, this system presents both remarkable advantages and disadvantages that warehouse managers must carefully evaluate.

The growing adoption of shuttle racking systems across industries like food distribution, pharmaceuticals, and e-commerce underscores their importance. However, without a thorough understanding of both the benefits and limitations of these systems, companies risk making costly investments that may not align with their operational needs.

This definitive guide provides an unbiased, expert-level examination of shuttle racking system advantages and disadvantages, offering warehouse operators the insights needed to make informed decisions. Drawing from real-world case studies and industry benchmarks, the analysis goes beyond surface-level features to explore practical implementation considerations. shuttle racking system advantages and disadvantages very important.

1. Understanding Shuttle Racking System Fundamentals

1.1 Core Components and Operational Mechanics

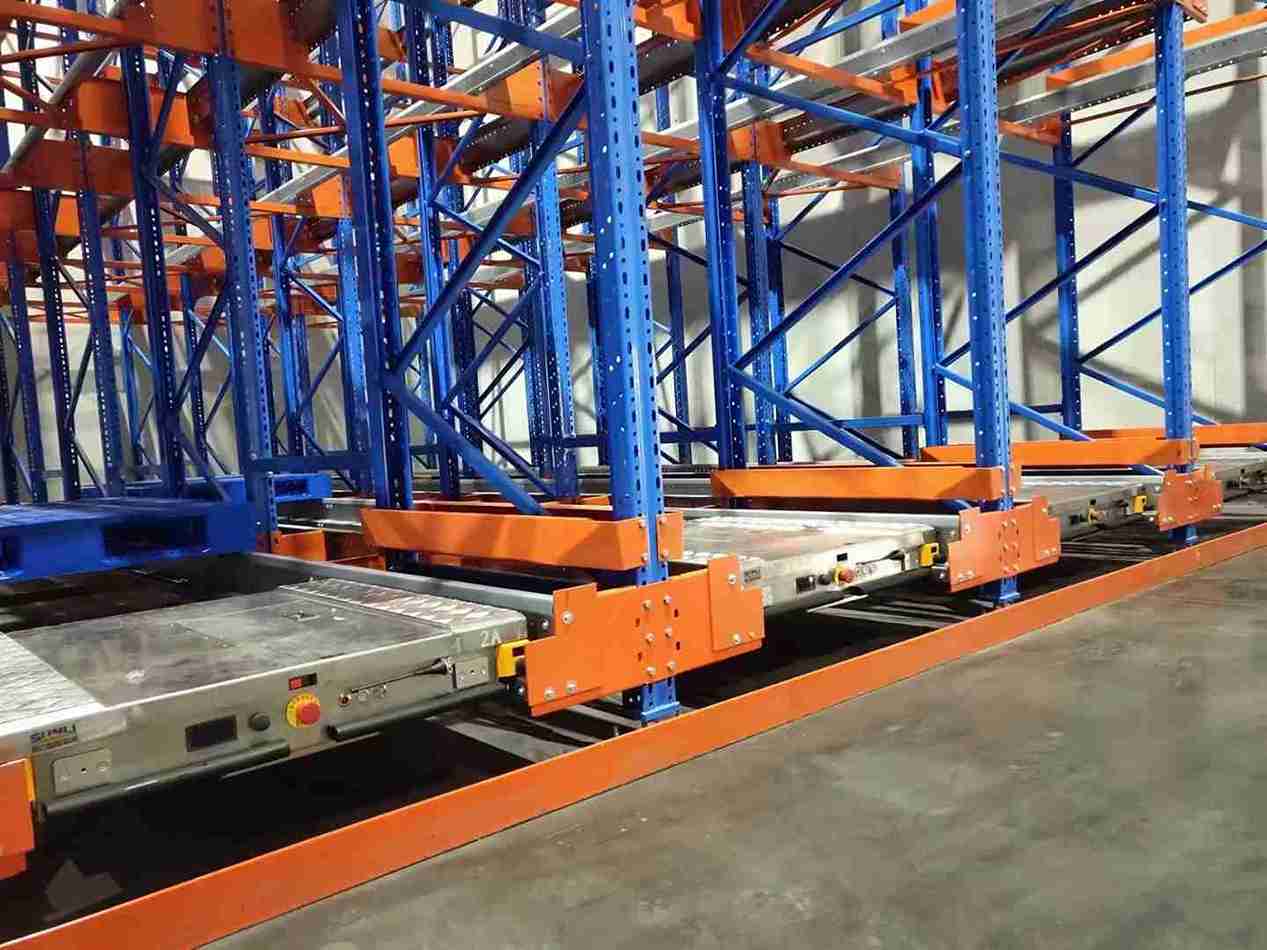

The shuttle racking system consists of three primary elements that work in concert to deliver its functionality:

Storage Structure: Heavy-duty steel frames designed for deep-lane storage, typically accommodating 5-30 pallets per lane

Motorized Shuttles: Battery-powered vehicles that travel on rails within storage lanes, capable of handling loads up to 1,500 kg

Control System: Software interface that manages shuttle movements, inventory tracking, and retrieval sequencing

Unlike conventional systems requiring forklift entry, the shuttle racking system operates on a “goods-to-operator” principle. When a pallet reaches the lane entrance via forklift or conveyor, the shuttle automatically:

Positions itself at the lane entrance

Engages with the pallet’s underside

Transports it to the optimal storage position

Returns to the entrance when summoned for retrieval

1.2 Key Variations in System Design

Modern shuttle racking systems offer several configuration options to meet diverse operational needs:

Single-Depth vs. Multi-Depth: Single-depth systems allow direct access to every pallet, while multi-depth configurations maximize storage density

Semi-Automated vs. Fully Automated: Semi-automated versions require manual shuttle positioning, while fully automated systems integrate with WMS for hands-off operation

Ambient vs. Cold Storage Models: Specialized versions maintain functionality in freezer environments as low as -30°C

These variations significantly impact both the advantages and disadvantages experienced in real-world applications, making proper system selection crucial.

2. The Five Transformative Advantages of Shuttle Racking Systems

2.1 Unparalleled Storage Density Optimization

The most celebrated of all shuttle racking system advantages is its ability to dramatically increase storage capacity. By eliminating the need for forklift aisles between every storage lane, these systems typically achieve:

75-90% floor space utilization compared to 40-50% with selective racking

Up to 60% more pallet positions within the same warehouse footprint

Vertical storage heights reaching 45m in specialized installations

For urban fulfillment centers facing extreme space constraints, this density advantage alone often justifies the investment in shuttle racking systems.

2.2 Operational Efficiency Breakthroughs

Beyond space savings, the shuttle racking system delivers measurable productivity gains:

3-5x faster pallet movements compared to manual forklift operations

Precision placement with <5mm positioning accuracy

Continuous operation capability with quick-change shuttle batteries

These efficiency advantages translate directly to labor cost reductions, with many operations reporting 30-40% decreases in staffing requirements for storage/retrieval functions.

2.3 Enhanced Inventory Control and Accuracy

The automated nature of shuttle racking systems introduces new levels of inventory management precision:

Real-time pallet tracking through integrated WMS connectivity

Elimination of misplacement errors common in manual systems

Automated stock rotation enforcing FIFO or LIFO protocols

For regulated industries like pharmaceuticals, these control advantages provide compliance assurance that manual systems simply cannot match.

2.4 Improved Workplace Safety Metrics

Among the most valuable shuttle racking system advantages is its safety performance:

85% reduction in forklift-related accidents

Elimination of high-risk deep-lane forklift maneuvers

Reduced worker fatigue from decreased manual handling

These safety improvements frequently lead to lower insurance premiums and workers’ compensation costs, further enhancing ROI.

2.5 Long-Term Cost Competitiveness

While the upfront investment is substantial, the shuttle racking system delivers compelling lifetime economics:

5-7 year payback periods in high-volume operations

20-30% lower operating costs versus traditional systems after year 3

15-20 year service life with proper maintenance

For growing operations, these financial advantages make shuttle systems a strategically sound capital allocation.

3. The Five Critical Disadvantages of Shuttle Racking Systems

3.1 Substantial Capital Requirements

The most significant of all shuttle racking system disadvantages is the initial investment:

$100-$300 per pallet position depending on automation level

$500,000+ for medium-sized installations

Additional costs for structural reinforcements, electrical work, and WMS integration

These figures place shuttle systems beyond reach for many small to mid-sized operations without access to significant capital.

3.2 Inflexibility for Dynamic Inventory Profiles

Certain operational realities amplify shuttle racking system disadvantages:

Minimum 10-15 pallets per SKU for economic viability

Poor suitability for SKUs with highly variable dimensions

Slow adaptation to inventory mix changes

Operations with highly seasonal or rapidly evolving product lines often find these constraints prohibitive.

3.3 Technical Complexity and Maintenance Demands

The sophisticated technology behind shuttle racking systems introduces new challenges:

Specialized technicians required for repairs

2-4 week lead times for replacement parts

Ongoing software updates and system recalibrations

Without proper technical support infrastructure, these disadvantages can lead to costly operational disruptions.

3.4 Throughput Limitations in Certain Configurations

Not all shuttle racking systems deliver equal performance:

Single-shuttle systems may create bottlenecks during peak demand

Deep-lane configurations slow retrieval times for rear-positioned pallets

Peak throughput typically capped at 50-70 pallets/hour per aisle

High-volume operations must carefully model these constraints during system design.

3.5 Climate Control Complications

In environmentally sensitive applications, shuttle racking system disadvantages emerge:

Battery performance degradation in extreme temperatures

Condensation issues when moving between temperature zones

Increased maintenance frequency in humid or corrosive environments

Specialized equipment modifications can mitigate but not eliminate these challenges.

4. Comparative Analysis: Shuttle Racking vs Alternative Systems

4.1 Shuttle Racking vs. AS/RS: The Automation Spectrum

While both systems offer automation advantages, key differences exist:

AS/RS provides higher throughput (100+ pallets/hour) but at 2-3x the cost

Shuttle systems offer better ROI for operations with <50 pallet movements/hour

Hybrid solutions are emerging that combine technologies

4.2 Shuttle Racking vs. Drive-In Racking: Density vs Accessibility

The density advantages of shuttle systems come with tradeoffs:

Drive-in racking allows faster access to all pallets

Shuttle systems provide better inventory control and rotation

Damage rates are typically lower with shuttle systems

4.3 Shuttle Racking vs. Mobile Racking: Flexibility Comparison

Mobile racking systems present an interesting alternative:

Mobile racking offers greater layout flexibility

Shuttle systems provide superior automation capabilities

Operational costs favor shuttle systems in high-volume scenarios

5. Implementation Considerations for Maximum ROI

5.1 Warehouse Layout Optimization Strategies

To maximize shuttle racking system advantages:

Aisle width must balance shuttle access and storage density

Picking zones should be strategically positioned

Future expansion pathways must be preserved

5.2 Workforce Training Requirements

Mitigating shuttle racking system disadvantages requires:

Dedicated system operators with technical training

Maintenance personnel certified on shuttle mechanics

Management training on performance analytics

5.3 Integration with Existing Systems

Successful implementations address:

WMS compatibility through API development

Legacy equipment interface requirements

Data reporting standardization

6. Future Trends in Shuttle Racking Technology

6.1 AI-Driven Predictive Maintenance

Emerging solutions are addressing shuttle racking system disadvantages:

Vibration sensors detecting impending failures

Usage pattern analysis optimizing maintenance schedules

Self-diagnosing shuttle units

6.2 Advanced Energy Recovery Systems

New designs enhance sustainability advantages:

Regenerative braking energy capture

Solar-assisted charging stations

Low-temperature battery innovations

6.3 Modular Expansion Capabilities

Future-proofing strategies include:

Plug-and-play shuttle additions

Hot-swappable component designs

Scalable control architectures

7. Conclusion: Making the Right Storage Automation Decision

The comprehensive analysis of shuttle racking system advantages and disadvantages reveals a solution that is neither universally perfect nor universally problematic. For the right operation – typically those with stable, high-volume pallet flows and sufficient capital – the advantages can be transformative. However, the disadvantages demand careful consideration and mitigation planning.

Key decision factors should include:

Pallet volume consistency

Available capital and ROI requirements

Existing workforce technical capabilities

Future growth projections

For operations where the shuttle racking system aligns well, the potential benefits in density, efficiency, and safety frequently justify the investment. Those considering implementation should engage with experienced consultants to conduct detailed feasibility studies before proceeding.The shuttle racking system advantages and disadvantages systems are important to the efficiency of your warehouse use.shuttle racking system advantages and disadvantages to understand clearly.

8. Frequently Asked Questions (FAQs)

8.1 Can shuttle racking be used in narrow-aisle warehouses?

Yes, but proper aisle width calculations are needed for shuttle movement.

8.2 What’s the lifespan of a shuttle racking system?

With proper maintenance, 15-20 years.

8.3 How much does a basic shuttle racking system cost?

Starting at $50,000, scaling up based on automation level.

8.4 Is shuttle racking better than pallet flow systems?

Depends on inventory turnover—pallet flow is better for fast-moving goods.

8.5 Can existing racking be converted into a shuttle system?

Sometimes, but structural modifications may be required.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com