📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

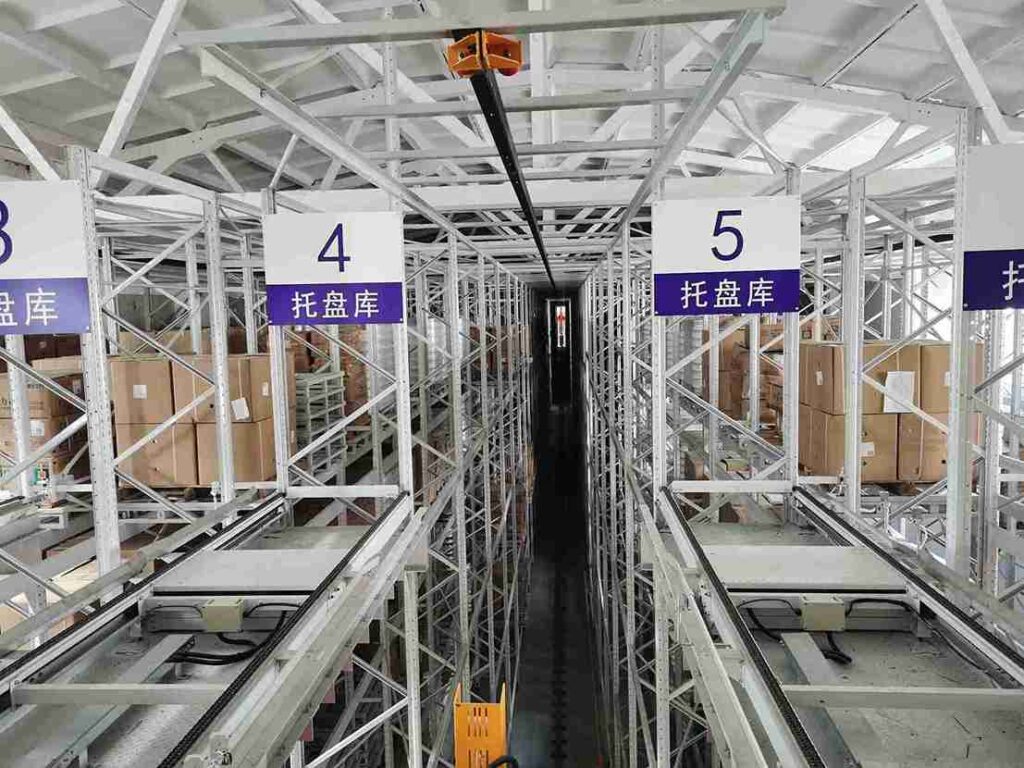

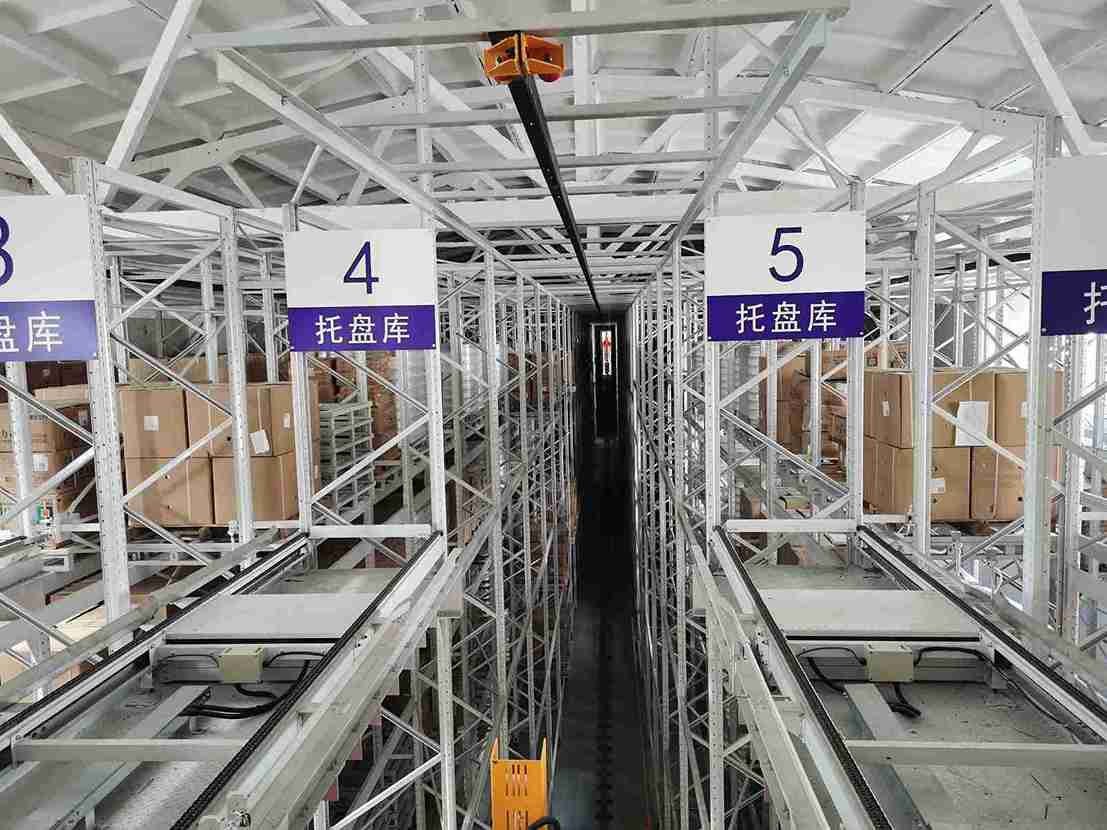

non-standard pallet on slave pallet in warehouse

What is a Slave Pallet?

A slave pallet is an auxiliary platform, typically made of wood, plastic, or metal, used to support another pallet — especially those that are non-standard in size or strength. It acts as a stable foundation for unit loads that otherwise can’t be handled efficiently in automated warehouse environments.

In automation-driven settings, the slave pallet ensures consistent base dimensions, improving compatibility with conveyors, stacker cranes, and robotic handling systems. When used exclusively in internal logistics networks, they are sometimes referred to as captive pallets.

If you need warehouse racking CAD drawings, we can do warehouse racking planning and design for free, you can consult us. Our email: jili@geelyracks.com.

Advantages of Using Slave Pallets

The use of slave pallets offers multiple operational benefits:

Stability: Creates a consistent base to reduce tipping and prevent damage.

Automation readiness: Enables smooth integration with AS/RS systems, pallet conveyors, and robotic forklifts.

Load protection: Shields fragile or irregular loads from direct contact with mechanical systems.

Space optimisation: Standardises unit dimensions for improved vertical and horizontal stacking.

Flexibility: Compatible with various load sizes, including half pallets or oversized packages.

Efficiency: Minimises the need for manual intervention, repacking, or reloading.

📸 Tip: Use these platforms as carriers for receiving incoming pallets of varying sizes and conditions.

Role in Automated Warehouses

In highly automated logistics operations, standardised dimensions are essential. The slave pallet plays a critical role in systems such as:

AS/RS (Automated Storage and Retrieval Systems)

Conveyor-based pallet movement

Autonomous Mobile Robots (AMRs)

If incoming pallets fail to meet required quality or dimensional standards, automation stackers can position them onto these base platforms, ensuring smooth transitions and minimising stoppages.

Use cases include:

Half pallets placed on these bases for uniform handling.

Incoming load inspection stations verifying combined height and condition.

Automated stackers positioning or removing pallets as required.

Real-World Use Cases

🔹 Clairefontaine (France)

Processes non-standard paper loads by placing them on support bases for storage within three automated facilities.

🔹 Ceramika Paradyz (Poland)

This tile manufacturer uses them for managing heavy ceramic loads, with stackers automating pallet substitution.

🔹 Steris (Global)

Applies them in sterile environments, where pallets are handled via automation and human access is restricted.

Practical Benefits Across Warehousing

These platforms are a cost-effective logistics solution, especially useful in:

Automated storage systems

Mixed-load or irregular load handling

In-house transport requiring standardised base dimensions

By unifying handling processes and improving operational flow, they help prevent downtime, reduce mechanical errors, and enhance safety across warehouse environments.

5 Key Questions About Slave Pallets

1. What is it used for?

To provide support under another pallet, particularly in automated environments where consistent base size is required.

2. Why use it?

It stabilises non-standard loads, reduces equipment damage, and improves automated system flow.

3. What materials are common?

Typically made of wood, metal, or durable plastic. Often conforms to Euro or custom formats.

4. How are they deployed?

Manually with forklifts or automatically via stacking equipment.

5. Why are they vital in automation?

They enable uniformity and safety, ensuring compatibility and reducing system stoppages.

✅ Conclusion

The slave pallet is a smart solution for modern warehouses dealing with high-speed automation and diverse load formats. From improving load stability to ensuring seamless equipment operation, it brings measurable value to:

Safety and equipment longevity

System uptime

Handling consistency

Operational efficiency

🧠 FAQ Section Summary (Structured Data Ready)

You can also format the above 5 questions for FAQ schema markup to enhance your Google Search visibility (Rich Snippets).

🔎 Explore more topics

How AS/RS Systems Work in Practice

Choosing the Best Base for Automated Handling

Half-Pallet Use in Robotic Storage Facilities

- Geelyracks specializes in the production of warehouse racks and is a global rack customization expert: https://geelyracks.com/

If you need warehouse racking CAD drawings, we can do warehouse racking planning and design for free, you can consult us. Our email: jili@geelyracks.com.