📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Executive Overview: The Definitive Storage Solution for Growth-Oriented Operations

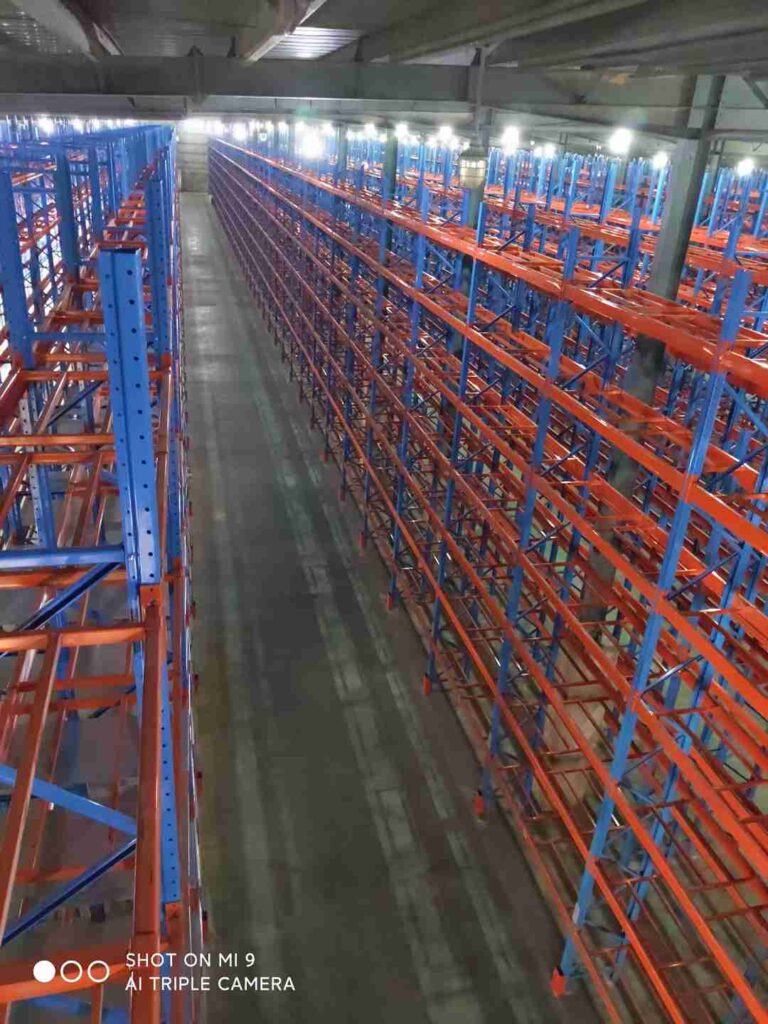

In the dynamic and competitive landscapes of Latin America, Central Asia, and other high-growth regions, logistics executives face a perpetual equation: balancing soaring storage demands against stringent cost controls and often limited physical footprints. The answer to this complex challenge lies not in mere expansion, but in intelligent, dense storage optimization. This definitive guide explores selective narrow aisle racking as the cornerstone of a modern, efficient warehouse strategy. Selective narrow aisle racking represents the optimal compromise between unparalleled storage density and the crucial need for 100% direct pallet access.

For operations ranging from burgeoning e-commerce fulfillment centers in São Paulo to industrial goods distributors in Tashkent, implementing a selective narrow aisle racking system is a transformative decision that directly impacts profitability, scalability, and operational agility. This article delves beyond basic specifications, providing a masterclass in planning, implementing, and maximizing the return on investment from a selective narrow aisle racking installation.

The Modern Warehouse Dilemma: Skyrocketing Costs Versus Finite Space

Logistics hubs across emerging economies are experiencing unprecedented pressure. Urban land values are climbing, consumer demand is diversifying at a rapid pace, and the imperative for faster delivery cycles is relentless. The traditional model of the wide-aisle warehouse, with its generous 3.5-meter-plus lanes for counterbalance forklifts, is increasingly revealed as a model of profound inefficiency. In such a layout, valuable square footage dedicated solely to vehicle transit can constitute over half of the total floor area. This is an unsustainable luxury, effectively monetizing empty air at premium real estate rates.

The operational costs compound this issue: longer travel distances for order picking, increased energy consumption for lighting and climate control, and an inherent ceiling on throughput capacity. The strategic mission for any forward-thinking warehouse manager is clear: to reclaim this wasted cubic volume. The solution must achieve this without sacrificing the fundamental principle of selective access—the immediate, unhindered reach to every single pallet—which is non-negotiable for operations with vast SKU counts and rapid inventory turnover. Herein lies the unparalleled value proposition of selective narrow aisle racking.

Engineering Excellence: The Technical Foundations of Selective Narrow Aisle Racking

Core Design Philosophy: Precision Symbiosis Between Rack and Machine

The brilliance of selective narrow aisle racking is found in its elegant engineering simplicity. It is not a wholesale reinvention of pallet storage but a rigorous optimization of the conventional selective racking concept. The system is meticulously designed to operate in perfect harmony with specialized material handling equipment, namely narrow aisle forklifts or turret trucks. These machines are the linchpin of the system, engineered to maneuver within aisle widths typically ranging from 1.6 to 2.0 meters. This dramatic reduction from standard aisle widths directly converts former traffic lanes into productive storage positions.

The machinery achieves this through innovative design: unlike a standard forklift that requires space to turn its entire body, a turret truck operates straight down the aisle, with its forks rotating 180 degrees or the mast executing precise lateral shifts to deposit or retrieve loads. The selective narrow aisle racking structure is built to more exacting tolerances than its wide-aisle counterpart, featuring robust upright frames, reinforced beam connections, and often protective column guards to ensure durability in a confined operating environment. Thus, a selective narrow aisle racking installation is a masterclass in symbiotic design.

Critical Specifications: Designing for Load, Safety, and Environment

Specifying a selective narrow aisle racking system is a foundational engineering exercise, not a simple procurement task. Success hinges on a deep analysis of several critical factors:

Dynamic and Static Load Profiles: Engineering must account for not just average weights, but maximum unit load dimensions and weights, including potential pallet overhang. Calculations for beam deflection and upright frame capacity under seismic loads are paramount.

Seismic and Regional Code Compliance: For logistics hubs in seismically active zones across Latin America’s Pacific coast or Central Asia, adherence to stringent standards like RMI ANSI MH16.1 is the baseline. A competent supplier will adapt the selective narrow aisle racking design to local building codes, ensuring specific bracing patterns, baseplate designs, and anchor specifications meet all regulatory safety requirements.

Floor Flatness and Quality: The performance of both the racking and the equipment is critically dependent on warehouse floor flatness. A proper selective narrow aisle racking project mandates a detailed floor survey and often a specification for new flooring to achieve a required flatness tolerance (e.g., FF50/FL40). An uneven floor leads to premature wear, operational inefficiency, and safety risks.

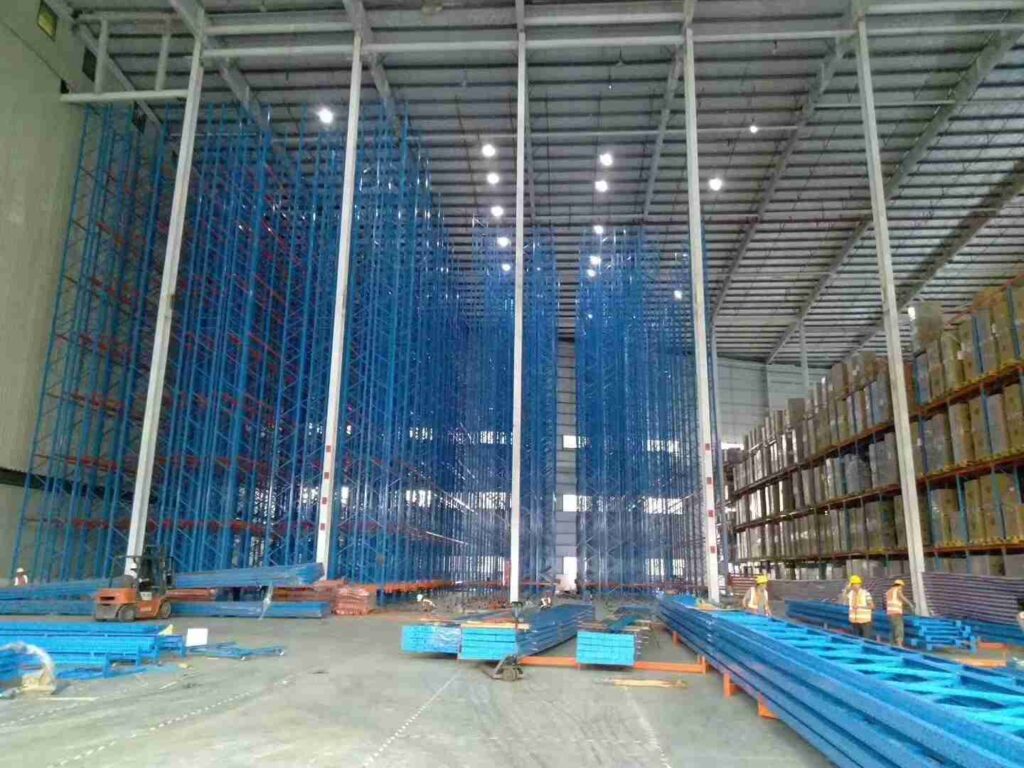

Vertical Clearance Optimization: True cubic space utilization means building upwards. A professional assessment will deduct necessary clearances for sprinklers, lighting, and ductwork from the gross clear height to determine the net usable storage height. This calculation is essential for maximizing the storage levels within a selective narrow aisle racking configuration.

The Compelling Economics: Quantifying the ROI of a Selective Narrow Aisle Racking System

The Density Multiplier: A Concrete Comparative Analysis

The financial argument for selective narrow aisle racking is compelling and easily quantifiable. Consider a hypothetical but realistic logistics facility in a key market like Bogotá or Almaty. The existing warehouse spans 12,000 square meters with a 11-meter clear height, utilizing standard wide-aisle racking to store approximately 10,000 pallets.

A transition to a selective narrow aisle racking system, with aisles reduced to 1.85 meters and the vertical storage profile fully optimized, reliably increases pallet positions by 40-60%. In this scenario, that translates to an additional 4,000 to 6,000 storage locations within the exact same building footprint.

The Return on Investment Calculation:

Cost Avoided (Space Acquisition): The capital outlay or long-term lease commitment for 5,000 square meters of additional warehouse space is eliminated. In premium logistics corridors, this can represent millions in saved or deferred capital.

Strategic Investment: The total project cost for a turnkey selective narrow aisle racking system, including high-quality racking, 3-4 narrow aisle turret trucks, and professional installation.

Net Result: The payback period for this strategic investment is frequently under 36 months, purely on the basis of avoided real estate costs. Beyond this point, the operation enjoys permanently lower fixed costs and a significantly higher storage asset yield per square meter.

Operational Efficiency: The Continuous Profit Engine

The financial benefits of selective narrow aisle racking extend far beyond static density gains. The redesigned, narrower layout fundamentally streamlines material movement:

Reduced Travel Time: Order picker travel distances can be reduced by 25-40%, directly increasing picks per hour and reducing labor costs per order.

Enhanced Throughput: With more concentrated storage and shorter travel paths, the same workforce can process a higher volume of orders, increasing facility output without expansion.

Lower Energy Overheads: Lighting and environmental control for a smaller total traffic area leads to measurable reductions in utility expenses.

Improved Inventory Accuracy and Safety: The organized, defined lanes of a selective narrow aisle racking system reduce cross-traffic, minimize product damage, and create a more predictable, safer workflow.

Market-Specific Advantages: Why Selective Narrow Aisle Racking Dominates in Growth Regions

Aligning with Regional Infrastructure and Economic Realities

The operational characteristics of selective narrow aisle racking make it exceptionally well-suited to the conditions prevalent in Latin American, Central Asian, and similar emerging markets.

Optimal Capital Allocation: For companies experiencing rapid growth but needing to manage capital expenditure prudently, selective narrow aisle racking offers a superior middle ground. It provides density close to that of fully automated systems without the associated high capital cost and technical complexity, representing a savvy, scalable investment.

Adaptability to Utility Constraints: The electrical power requirements for a fleet of efficient, opportunity-charged narrow aisle forklifts are more manageable and less sensitive to grid instability than the constant, high-demand power needs of some fully automated Automated Storage and Retrieval Systems (ASRS).

Workforce Development Synergy: Training personnel to operate a turret truck within a selective narrow aisle racking system is a focused, achievable skills upgrade. It cultivates a more technical workforce without requiring the specialized engineers needed to maintain robotic systems, aligning with local labor market development.

Unmatched Inventory Flexibility: Markets subject to shifts in import/export goods benefit immensely from the 100% selectivity of selective narrow aisle racking. Inventory of any product type can be stored and retrieved independently, providing vital agility in volatile trading environments.

Enabling Advanced Regional Logistics Models

National and regional governments are heavily investing in logistics corridors and Special Economic Zones. Businesses within these zones compete on efficiency. A well-implemented selective narrow aisle racking system directly enables key logistics models:

Cross-Docking Efficiency: Provides high-density, short-term buffer storage for inbound and outbound loads, speeding up transfer operations.

Vendor-Managed Inventory (VMI) Support: Allows multiple suppliers’ goods to be stored on-site in a structured, accessible manner, facilitating just-in-time replenishment.

Multi-Tier Storage Integration: The system seamlessly integrates with mezzanine structures for case picking or with automated conveyors for sortation, creating a high-density backbone for a multi-modal distribution center.

The Implementation Blueprint: A Phased Approach to Guaranteed Success

Phase 1: Comprehensive Data Analysis and 3D Simulation

A successful selective narrow aisle racking project begins with intelligence, not installation. The first phase involves a meticulous audit of current operations: pallet flow maps, SKU velocity analysis (using ABC principles), peak season data, and a clear understanding of future growth projections. Leading consultants employ advanced warehouse simulation software to create a digital twin of the proposed selective narrow aisle racking layout. This virtual model is stress-tested with typical and peak-day order profiles to validate throughput capacity, identify potential bottlenecks at receiving or shipping, and optimize the put-away and picking logic. This data-driven approach de-risks the investment by providing a performance forecast before a single rack is erected.

Phase 2: Integrated System Design and Equipment Synergy

This phase is where a supplier’s expertise as an integrated solutions provider becomes critical. The design of the selective narrow aisle racking must be meticulously coordinated with the chosen material handling equipment. Key considerations include:

Vehicle Selection Analysis: Determining the optimal choice between guided (wire or rail) turret trucks for ultimate precision and aisle minimization, versus non-guided models for greater layout flexibility.

WMS Integration Strategy: The location addressing schema for the selective narrow aisle racking must be designed for seamless integration with the Warehouse Management System to enable optimized put-away and picking paths, cycle counting, and inventory accuracy.

Safety and Compliance Detailing: This includes finalizing anchorage designs for the specific slab composition, specifying safety netting or barrier requirements, and ensuring all designs meet or exceed local safety regulations.

Phase 3: Precision Installation and Comprehensive Knowledge Transfer

The quality of installation directly dictates the long-term performance and safety of the selective narrow aisle racking system. Certified installation teams follow rigorous protocols for upright plumbness, beam level verification, and anchor torque settings. Post-installation, a series of inspections and load tests are conducted. Concurrently, a formal operator training program is essential, covering not only the safe operation of the narrow aisle equipment but also the specific protocols for working within the selective narrow aisle racking environment, including pedestrian awareness, load handling precision, and routine inspection checklists.

The Evolutionary Platform: Integrating Selective Narrow Aisle Racking with Next-Generation Automation

The Gateway to Automation: Synergy with AGVs and Robotics

A selective narrow aisle racking system should not be viewed as an end-state, but as a high-density platform ready for integration with broader automation. This is where its strategic value multiplies. Consider a hybrid model: Automated Guided Vehicles (AGVs) or unmanned forklifts manage the long-distance horizontal transport of pallets from the receiving dock to the aisle entrances. At this transfer point, a manned or even automated turret truck within the selective narrow aisle racking aisles executes the final storage or retrieval. This approach combines the labor-saving benefits of automation for repetitive horizontal moves with the dense storage and selectivity of the selective narrow aisle racking system, offering a practical, phased path toward higher levels of automation.

Creating a Holistic Material Flow Ecosystem

The high-density reserve storage provided by a selective narrow aisle racking system is the perfect feeder for dynamic order fulfillment technologies. Fast-moving SKUs can be replenished from the selective narrow aisle racking bulk storage into forward pick areas such as vertical lift modules (VLMs), carousels, or automated pick-to-light zones served by conveyor systems. This creates a tiered storage strategy that maximizes both space utilization and picking efficiency. An experienced integrator can design this entire flow, ensuring smooth, synchronized movement from the depths of the selective narrow aisle racking system to the shipping sorter.

The Strategic Imperative for Competitive Logistics Hubs

In the fast-paced commercial landscapes of Latin America, Central Asia, and beyond, warehouse optimization is not a luxury—it is a strategic imperative for survival and growth. For logistics managers seeking a proven, reliable, and high-return method to reduce costs and save space, the evidence overwhelmingly supports selective narrow aisle racking as the optimal solution. This system masterfully balances the critical need for direct pallet accessibility with the density required to maximize the value of every cubic meter of warehouse space.

Selective narrow aisle racking is more than a storage product; it is a strategic operational philosophy. It builds local capability, leverages global engineering standards, and provides an immediate financial return while establishing a solid, flexible foundation for future technological augmentation. For any organization looking to enhance its logistics competitiveness, investing in a professionally designed and implemented selective narrow aisle racking system is one of the most impactful decisions it can make. The journey toward a leaner, more responsive, and more profitable operation begins with optimizing the space you already control, and selective narrow aisle racking is the most effective tool to achieve that goal.

FAQs: Expert Insights on Selective Narrow Aisle Racking

Q1: What is the typical lifespan of a selective narrow aisle racking system, and how does maintenance differ from standard racking?

A high-quality selective narrow aisle racking system, designed to appropriate standards and properly maintained, has a functional lifespan of 20+ years. Maintenance focuses on two areas: the rack structure and the specialized equipment. The racking itself requires regular inspections for accidental damage, ensuring all bolts are torqued, and verifying upright plumb. This is more critical than with wide-aisle racking due to the tighter operating tolerances. The narrow aisle forklifts require strict adherence to planned maintenance schedules for their more complex mast and guidance systems. The total maintenance cost is often offset by the significantly longer travel life of the equipment, which operates in a confined, less punishing environment than a counterbalance forklift used for multiple tasks.

Q2: Can selective narrow aisle racking be effectively used in cold storage or freezer environments?

Absolutely. Selective narrow aisle racking is highly effective in cold storage, where the cost of cooled space is exceptionally high, maximizing density is paramount. The implementation requires specific considerations: the racking steel and hardware must be specified for low-temperature environments (often with specialized finishes), and the narrow aisle forklifts must be equipped with cold storage packages, including special hydraulics, oils, and operator compartment heaters. The efficiency gains from a selective narrow aisle racking system in a freezer—reducing the volume of air that needs to be cooled and minimizing the time doors are open for vehicle entry—can lead to dramatic energy savings.

Q3: How does the choice of pallet type (wood, plastic, metal) impact the design of a selective narrow aisle racking system?

The pallet is a critical component of the load unit and directly influences the selective narrow aisle racking design. Key factors include:

Dimensions & Tolerance: Plastic and metal pallets often have more consistent dimensions than wood, allowing for slightly tighter aisle specifications.

Bottom Surface Design: Pallet entry (open boards vs. solid deck) affects beam type selection and forklift fork design.

Weight and Load Distribution: The system’s dynamic and static load calculations are based on the worst-case pallet and product combination.

A professional design process always begins with a full analysis of all pallet types used in the facility.

Q4: What are the most common mistakes companies make when planning a selective narrow aisle racking project?

Several pitfalls can undermine the success of a selective narrow aisle racking project:

Neglecting Floor Flatness: Assuming the existing floor is adequate without a professional survey, leading to poor equipment performance and safety issues.

Underestimating Future Growth: Designing the system for today’s needs without a clear buffer for medium-term growth, limiting the system’s usable life.

Siloed Procurement: Purchasing the racking, forklifts, and WMS from different vendors without ensuring seamless integration, leading to operational gaps and finger-pointing.

Insufficient Operator Training: Treating equipment training as an afterthought rather than a core part of the project, resulting in low productivity, high damage rates, and safety incidents.

Q5: How does selective narrow aisle racking compare to other high-density systems like drive-in or push-back racking in terms of selectivity and stock rotation?

This is a fundamental comparison. Selective narrow aisle racking offers 100% selectivity, meaning every pallet is accessible at any time without moving another. This supports First-In, First-Out (FIFO) or First-Expired, First-Out (FEFO) inventory control perfectly. In contrast, drive-in racking is a high-density, last-in, first-out (LIFO) system where selectivity is very low—to reach a pallet in the back, you must move all pallets in front of it.

Push-back racking offers better selectivity than drive-in but still operates on a LIFO principle within each lane (typically 2-6 pallets deep). Therefore, for operations requiring strict lot control, high SKU counts, or fast turnover, selective narrow aisle racking is the only high-density solution that maintains full inventory control and access.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com