📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

High-density storage has become a decisive competitive factor in modern warehousing. Across manufacturing, third-party logistics, retail distribution, e-commerce fulfillment, cold storage, and industrial supply chains, decision-makers are actively searching for storage systems that maximize space utilization while maintaining operational flexibility. High-Density Narrow Aisle Racking has proven to be one of the most reliable and scalable solutions to meet these demands.

This in-depth guide presents a comprehensive, experience-driven analysis of High-Density Narrow Aisle Racking, focusing on how it increases storage density, improves inventory accessibility, supports automation, and delivers long-term operational value. Written from a third-person industry perspective, the article reflects decades of practical expertise in warehouse racking and automated logistics systems, offering actionable insights for global markets including Southeast Asia, Central Asia, the Middle East, Africa, and Latin America.

1. Why High-Density Narrow Aisle Racking Has Become a Global Standard

Warehousing strategies have evolved significantly over the past decade. Rising land prices, limited industrial space, and increasing SKU complexity have forced warehouse operators to rethink traditional wide-aisle layouts. In this context, High-Density Narrow Aisle Racking has emerged as a preferred solution for organizations seeking higher storage capacity without expanding building footprints.

Unlike conventional pallet racking, High-Density Narrow Aisle Racking reduces aisle widths while preserving full pallet selectivity. This balance between density and accessibility makes it especially attractive for facilities handling diverse product ranges and fluctuating demand.

1.1 Market Drivers Behind High-Density Narrow Aisle Racking

Several structural factors continue to accelerate the adoption of High-Density Narrow Aisle Racking:

- Urbanization and scarcity of industrial land

- Growth of e-commerce and omnichannel fulfillment

- Rising labor and energy costs

- Increasing demand for automation-ready storage systems

These drivers have positioned High-Density Narrow Aisle Racking as a long-term investment rather than a short-term optimization.

2. Operational Principles of High-Density Narrow Aisle Racking

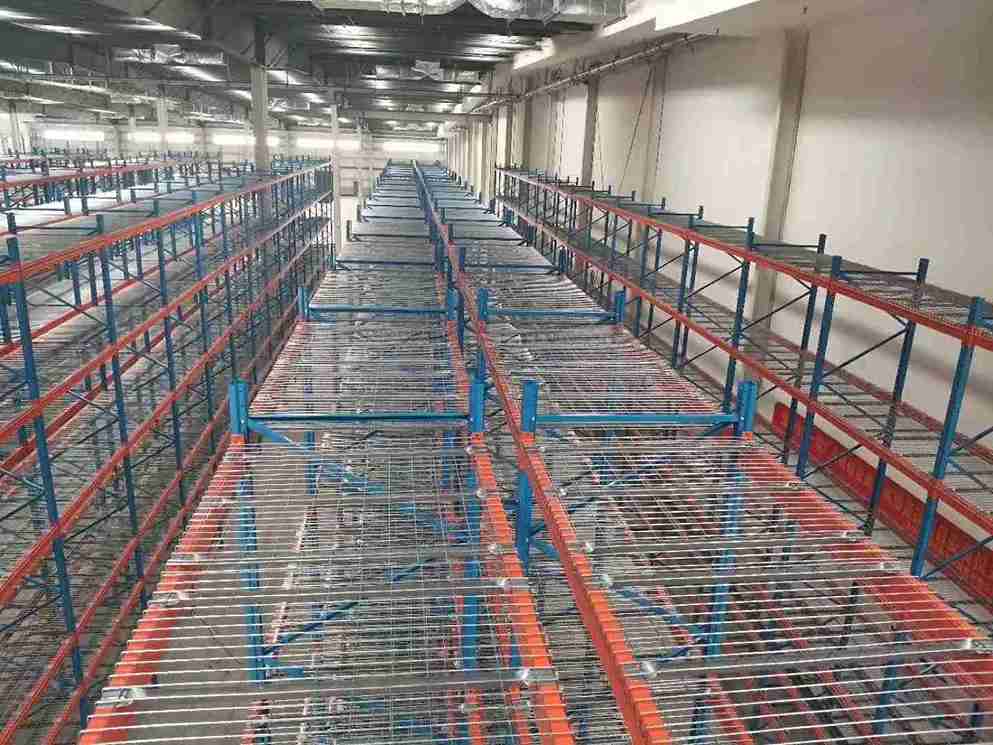

At an operational level, High-Density Narrow Aisle Racking is defined by precise aisle geometry, specialized material handling equipment, and engineered structural tolerances. Typical aisle widths range from 1.6 to 2.0 meters, significantly narrower than traditional selective racking layouts.

This configuration allows warehouses to increase pallet positions by up to 50% while maintaining orderly, highly controlled material flow.

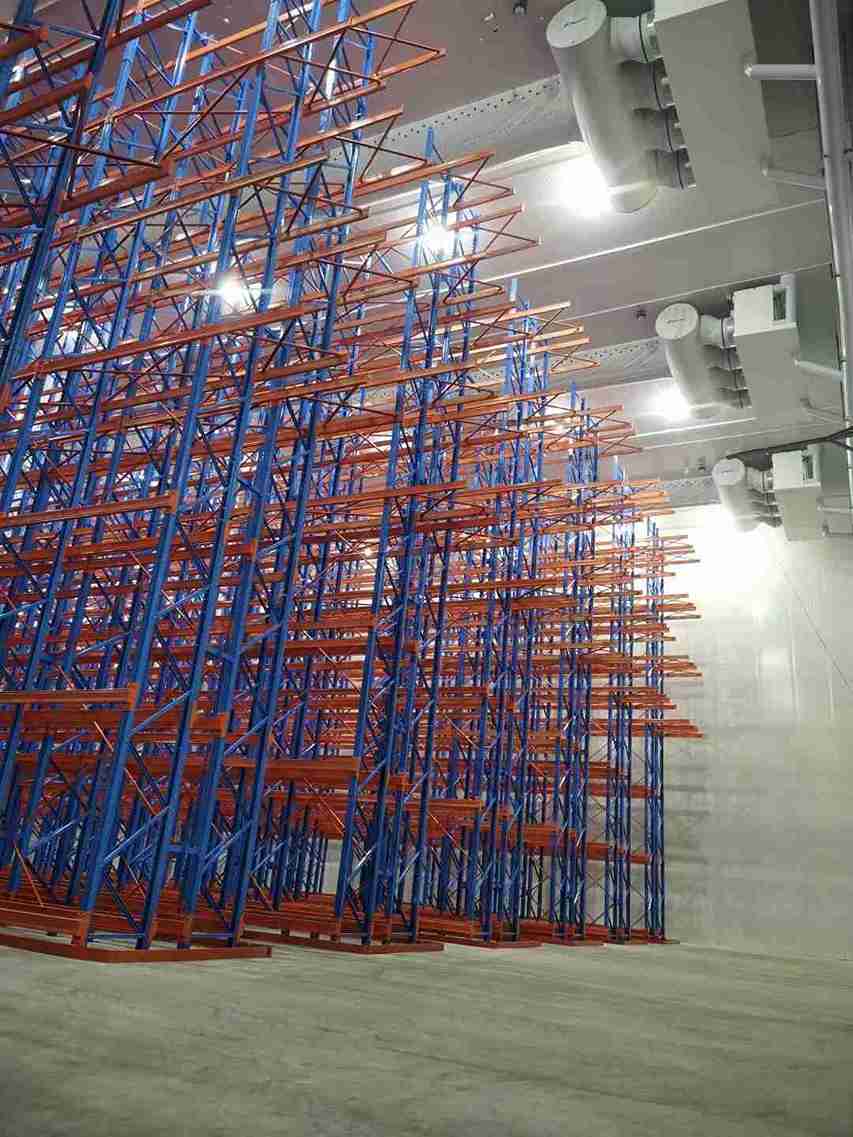

2.1 Vertical Space Optimization

One of the most overlooked advantages of High-Density Narrow Aisle Racking is vertical space utilization. Many warehouses operate far below their maximum clear height. By combining narrow aisles with taller rack structures, facilities can unlock unused cubic volume and dramatically increase storage density.

3. Structural Engineering Behind High-Density Narrow Aisle Racking

The performance of High-Density Narrow Aisle Racking depends heavily on structural engineering. Uprights, beams, bracing, and anchors must be designed to handle higher loads, greater heights, and dynamic forces generated by VNA equipment.

High-quality systems are manufactured using high-tensile steel, precision roll-forming, and strict quality control protocols. Load calculations are verified against international standards to ensure long-term reliability.

3.1 Load Capacity and Stability Considerations

In High-Density Narrow Aisle Racking, load distribution is more critical due to reduced lateral clearances. Engineers must account for:

- Pallet weight variability

- Rack deflection limits

- Seismic and wind loads (where applicable)

Properly engineered High-Density Narrow Aisle Racking systems deliver stability even at heights exceeding 15 meters.

4. Guidance Systems Used in High-Density Narrow Aisle Racking

Precise guidance is essential for safe and efficient operation in High-Density Narrow Aisle Racking environments. Common guidance solutions include:

- Wire-guided systems embedded in the floor

- Rail-guided systems mounted at aisle level

- Laser or camera-based guidance for automated vehicles

These systems reduce the risk of rack impact and enable consistent high-speed operation.

5. Equipment Compatibility and Material Handling Integration

High-Density Narrow Aisle Racking is closely linked with specialized material handling equipment. Very Narrow Aisle forklifts, turret trucks, and articulated reach trucks are commonly deployed to maximize system efficiency.

Increasingly, High-Density Narrow Aisle Racking is also designed to support AGVs and automated pallet handling solutions, creating a smooth transition toward smart logistics.

5.1 VNA Forklifts in High-Density Narrow Aisle Racking

VNA forklifts are engineered to operate within the tight clearances of High-Density Narrow Aisle Racking. Their rotating forks and guided travel paths enable precise pallet placement, even at extreme heights.

6. Comparison with Other High-Density Storage Systems

When evaluating warehouse storage options, High-Density Narrow Aisle Racking is often compared with alternative high-density systems.

6.1 Narrow Aisle Racking vs. Drive-In Racking

Drive-in systems offer high density but limited selectivity. High-Density Narrow Aisle Racking maintains full access to every pallet, making it more suitable for operations with multiple SKUs.

6.2 Narrow Aisle Racking vs. Shuttle Racking

Shuttle systems excel in deep-lane storage. However, High-Density Narrow Aisle Racking provides greater flexibility and simpler maintenance for mixed inventory environments.

6.3 Narrow Aisle Racking vs. AS/RS

Automated systems deliver high throughput but require significant capital investment. High-Density Narrow Aisle Racking offers a scalable path toward automation with lower initial cost.

7. Industry Applications of High-Density Narrow Aisle Racking

High-Density Narrow Aisle Racking is widely adopted across industries:

- Manufacturing and spare parts storage

- 3PL and contract logistics facilities

- E-commerce and omnichannel distribution centers

- Cold storage and temperature-controlled warehouses

- FMCG and retail distribution hubs

Each application benefits from increased capacity and improved inventory control.

8. Safety, Compliance, and Operational Reliability

Safety is a core consideration in High-Density Narrow Aisle Racking design. Protective measures include rack guards, end-of-aisle barriers, load backstops, and anti-collapse mesh.

Routine inspections and operator training are essential to maintaining long-term system integrity.

9. Lifecycle Cost Benefits of High-Density Narrow Aisle Racking

When evaluated over its lifecycle, High-Density Narrow Aisle Racking delivers measurable financial benefits:

- Reduced land and construction costs

- Lower energy consumption per pallet

- Improved labor productivity

- Compatibility with future automation upgrades

These advantages make High-Density Narrow Aisle Racking a sustainable long-term solution.

10. Best Practices for Implementing High-Density Narrow Aisle Racking

Successful implementation of High-Density Narrow Aisle Racking requires careful planning, accurate data analysis, and close coordination between racking engineers, equipment suppliers, and warehouse operators.

Phased installation strategies help minimize operational disruption and ensure a smooth transition.

Conclusion

High-Density Narrow Aisle Racking represents a strategic approach to warehouse optimization rather than a simple storage upgrade. By maximizing space utilization, maintaining full selectivity, and supporting automation, it enables warehouses to adapt to evolving supply chain demands. For organizations seeking scalable, future-ready storage solutions, High-Density Narrow Aisle Racking continues to set the benchmark for efficiency and reliability.

Frequently Asked Questions

1. How does the structural design of a High-Density Narrow Aisle Racking system differ from standard selective pallet racking to handle higher seismic loads in regions like Indonesia?

The design philosophy for a seismic-rated High-Density Narrow Aisle Racking system is fundamentally more robust. While standard racking may rely on simple diagonal bracing, a seismic design for High-Density Narrow Aisle Racking often incorporates moment-resisting frames (MRFs) at the end of runs and increased horizontal bracing at multiple levels. Connections are engineered to resist both shear and tensile forces, preventing progressive collapse. Upright sections may be heavier gauge, and specific load configurations account for dynamic amplification. A competent engineer will design the High-Density Narrow Aisle Racking system using relevant local codes (like SNI in Indonesia) or international standards (like FEM 10.2.08), performing specific seismic calculations that go far beyond the static load analysis used for standard applications.

2. What is the typical process for retrofitting an existing live warehouse with a High-Density Narrow Aisle Racking system without shutting down completely?

A phased retrofit is a complex but routine operation for experienced providers. It begins with a detailed master plan for the entire High-Density Narrow Aisle Racking installation. The warehouse is then strategically segmented into zones. Operations are gradually consolidated into specific areas while the first zone is cleared, demoed (if old racking exists), and the new High-Density Narrow Aisle Racking is installed. Once operational in that zone, inventory is shifted, and the process rolls into the next zone.

This “rolling thunder” approach requires meticulous inventory planning, temporary staging areas, and sometimes the use of temporary equipment. The core of the High-Density Narrow Aisle Racking rapid deployment methodology—pre-fabrication, kitting, and synchronized crews—is even more critical here to minimize the duration each zone is offline.

3. Can a High-Density Narrow Aisle Racking system be effectively used for cooler or cold storage environments, such as for food and beverage 3PLs?

Absolutely, and it is a highly efficient solution for cold storage where space is exceptionally expensive. The High-Density Narrow Aisle Racking system itself must be specified with materials suitable for low-temperature and high-humidity conditions, often requiring a superior galvanization specification. The greater consideration is the material handling equipment. Man-down turret trucks are typically preferred for very cold environments (e.g., -25°C freezer) as the operator remains in a (heated) cabin at ground level.

These trucks are built with cold-rated hydraulics, seals, and electronics. The guidance system (often wire-guided for reliability in cold temps) and the High-Density Narrow Aisle Racking layout must account for potential ice buildup on floors. The density gains from the High-Density Narrow Aisle Racking system directly reduce the volume of refrigerated space that needs to be cooled and maintained, leading to significant ongoing energy savings.

4. What are the key software and data requirements needed from our side to ensure an optimal High-Density Narrow Aisle Racking layout design?

The more data provided, the more optimized the High-Density Narrow Aisle Racking design will be. Critical inputs include:

SKU Master Data: Dimensions (pallet footprint and height), weight, and turnover velocity (ABC analysis) for every stock type.

Inventory Profiles: Maximum and average inventory levels per SKU to determine lane depths (e.g., how many pallets deep per SKU).

Order Histograms: Data on picking patterns (full pallet vs. case picking) to determine the optimal ratio of pallet racking to carton flow modules within the High-Density Narrow Aisle Racking zone.

Growth Forecasts: Projected increases in SKU count or volume to design scalability into the High-Density Narrow Aisle Racking layout from day one.

WMS Data: Understanding how your WMS currently assigns locations helps in designing a logical location numbering scheme that integrates seamlessly with the new High-Density Narrow Aisle Racking system.

5. How does the long-term total cost of ownership (TCO) compare between a High-Density Narrow Aisle Racking system with specialized trucks and a traditional system with standard forklifts?

While the initial capital outlay for a High-Density Narrow Aisle Racking system and its dedicated narrow aisle trucks is often higher, the TCO over a 10-15 year period is frequently lower. The analysis must include:

Real Estate Savings: The ongoing avoided cost of additional leased space is a massive credit to the High-Density Narrow Aisle Racking TCO.

Operational Efficiency: Lower energy consumption per pallet moved (narrow aisle trucks are often electric and travel shorter distances), reduced labor hours per order, and lower product damage all contribute to a lower operating cost for the High-Density Narrow Aisle Racking solution.

Maintenance Costs: Narrow aisle trucks, while sophisticated, are designed for the specific task and often have lower long-term maintenance costs than multi-purpose counterbalance forklifts subjected to tougher wear.

Residual Value: A well-maintained, high-quality High-Density Narrow Aisle Racking system has a strong residual value and can be reconfigured for future needs, whereas traditional wide-aisle racking offers less flexibility.

A detailed TCO model will almost always reveal that the High-Density Narrow Aisle Racking system provides a superior financial return over its lifecycle.

11. High-Density Narrow Aisle Racking Solutions for Middle East Markets

In the Middle East, warehouse development is strongly driven by national logistics strategies, free trade zones, and the rapid expansion of regional distribution hubs. Countries such as the UAE, Saudi Arabia, Qatar, Oman, and Kuwait continue to invest heavily in logistics infrastructure to support import–export activity, manufacturing diversification, and fast-growing e-commerce sectors. Within this context, High-Density Narrow Aisle Racking has become a core storage solution for modern warehouse facilities.

Warehouses in the Middle East are typically designed with generous clear heights, large footprints, and high-performance concrete floors. These structural characteristics make them particularly suitable for tall High-Density Narrow Aisle Racking installations combined with VNA forklifts or semi-automated handling equipment. By reducing aisle widths and increasing

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com