📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Definitive Guide to Maximizing Warehouse Efficiency: A Deep Dive into Advanced Narrow Aisle Pallet Rack Designs

In the relentless pursuit of logistical supremacy, the modern warehouse is no longer a static repository but a dynamic, high-throughput engine. At the heart of this transformation lies a critical, often under-optimized component: the storage infrastructure. For operations targeting growth in demanding markets like Southeast Asia, the Middle East, Africa, and Latin America, where space is at a premium and operational agility is non-negotiable, conventional storage solutions fall short.

The strategic implementation of engineered narrow aisle pallet rack designs emerges as the foundational pillar for achieving unparalleled storage density, operational speed, and cost-effectiveness. This comprehensive resource transcends basic overviews, offering a masterclass in how next-generation narrow aisle pallet rack designs, when expertly configured for synergy with Automated Guided Vehicles (AGVs) and automated forklifts, can redefine warehouse performance. It serves as an essential blueprint for logistics managers, warehouse designers, and business owners aiming to build a future-proof, competitive operation.

The Strategic Imperative: Why Narrow Aisle Pallet Rack Designs Are Non-Negotiable

The global shift toward e-commerce fulfillment, just-in-time manufacturing, and expansive SKU counts has turned cubic storage space into a directly monetizable asset. Traditional wide-aisle configurations, often requiring 12 to 13 feet for forklift maneuverability, represent a profound waste of this asset—translating directly into higher real estate costs, inefficient energy use for lighting and climate control, and longer travel times for material handling equipment.

Engineered narrow aisle pallet rack designs systematically eliminate this waste by reducing aisle widths to between 5.5 and 8 feet. This single architectural shift can increase storage capacity by 40-50% within the same building footprint. However, the superiority of advanced narrow aisle pallet rack designs extends far beyond pure density:

Enhanced Operational Safety: Fewer and narrower aisles mean less cross-traffic and reduced potential for collisions. High-quality narrow aisle pallet rack designs incorporate integrated column guards, robust impact protection, and clear visibility lines, creating a safer environment for both automated and manual equipment.

Improved Inventory Control & Accuracy: The high-density, organized nature of these systems simplifies inventory management. When integrated with a Warehouse Management System (WMS), each location within the narrow aisle pallet rack designs becomes a precise, trackable address, drastically reducing mis-picks and lost stock.

Energy and Cost Synergies: A smaller operating footprint directly reduces lighting, ventilation, and heating/cooling requirements. This is a critical operational advantage in regions like the Middle East with high cooling costs or in large facilities across Latin America. The efficiency gains from narrow aisle pallet rack designs contribute significantly to the total cost of ownership (TCO) model.

For businesses in rapidly industrializing regions—from the bustling ports of Vietnam to the manufacturing hubs in Mexico—adopting these high-density systems is not merely an upgrade; it is a strategic imperative for maintaining margin and scalability.

The Evolution of Storage: From Static Racking to Intelligent, Automated Systems

The journey from basic bulk storage to today’s intelligent warehousing solutions mirrors the broader arc of industrial innovation. First-generation pallet racking solved the simple problem of vertical stacking. The advent of narrow aisle pallet rack designs marked the second wave, focusing on spatial optimization within the aisle.

Today, we are in the third wave: the era of integrated automation-ready storage. The most advanced narrow aisle pallet rack designs are no longer passive steel structures. They are active, data-connected components of a holistic automated material handling system. They are conceived from the outset to communicate with, guide, and be accessed by robotic systems. This evolution means that specifying narrow aisle pallet rack designs now requires a forward-looking mindset, considering not just today’s manual forklifts but tomorrow’s fleet of AGVs and autonomous mobile robots (AMRs). Leading providers design with this interoperability as a core principle, ensuring that their narrow aisle pallet rack designs serve as a perpetual platform for innovation.

Deconstructing the Design: Anatomy of High-Performance Narrow Aisle Systems

Not all narrow aisle pallet rack designs are created equal. Performance, durability, and automation compatibility are determined by specific engineering choices. Key design elements include:

Structural Integrity & Dynamic Load Rating: Unlike static racking, systems designed for use with AGVs and high-speed forklifts must account for dynamic forces—the slight impacts, vibrations, and shear forces during high-speed traversal and load placement. Premium narrow aisle pallet rack designs use high-strength, cold-rolled steel with increased yield strength and are calculated to withstand these repeated dynamic loads over a decades-long lifespan.

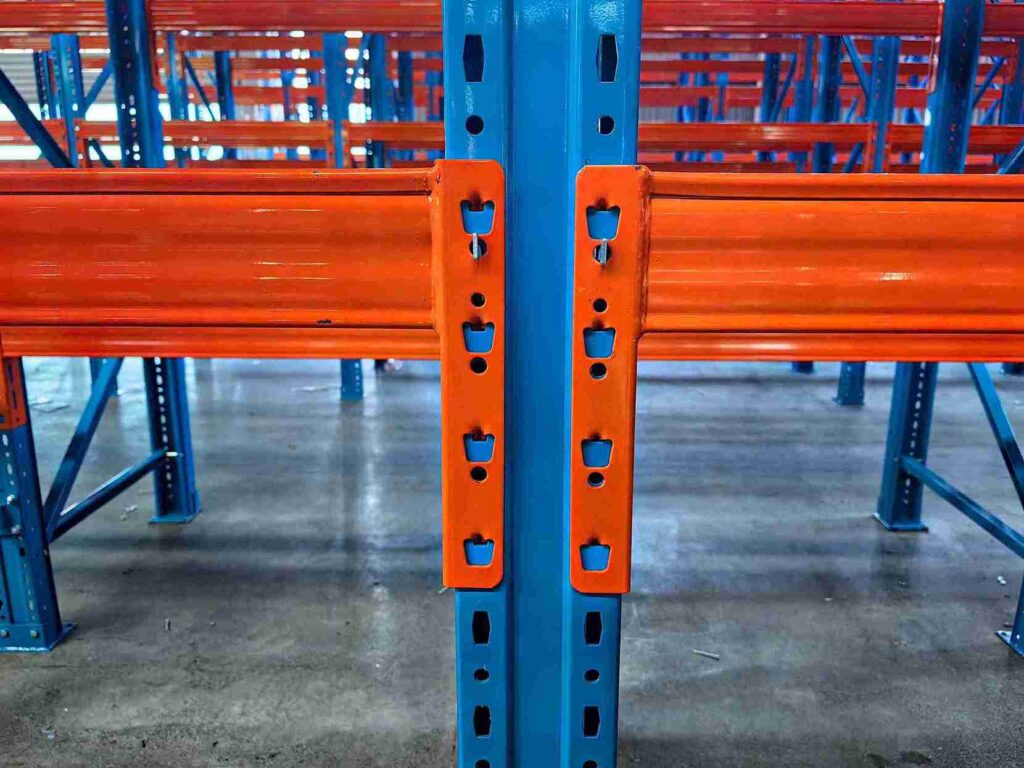

Precision Tolerances & Alignment: Successful AGV integration demands millimeter-level precision. The upright frames, guide rails, and load beams in automation-ready narrow aisle pallet rack designs are manufactured and installed with exceptional tolerance control. This ensures that navigation systems (laser, vision, or tape-based) on AGVs can operate flawlessly, aisle after aisle, without positioning errors.

Integrated Guidance & Protection Systems: True AGV-ready narrow aisle pallet rack designs often feature built-in guidance solutions. This may include embedded inductive wire channels in the floor, dedicated mounting points for magnetic or optical tape, or protective urethane guides on the rack base that also serve as physical navigation aids for the AGV. Impact protection is seamlessly integrated into the structure, not added as an afterthought.

Accessibility for Maintenance: Intelligent narrow aisle pallet rack designs consider the entire lifecycle. Modular designs with easily replaceable components, clear access for inspection, and designs that facilitate cleaning and maintenance in harsh environments (like dust-prone areas in Africa or humid climates in Southeast Asia) are hallmarks of a superior system.

AGV Integration: Engineering the Symbiosis Between Rack and Robot

The promise of automation is fully realized only when the storage infrastructure speaks the same language as the robots. Integrating AGVs into a warehouse is more than just programming paths; it requires the physical environment to be meticulously prepared. This is where purpose-built AGV-ready narrow aisle pallet rack designs become the critical enabler.

Navigation Compatibility: The rack layout must be optimized for the AGV’s navigation type. For laser-guided vehicles (LGV), the narrow aisle pallet rack designs must be laid out to ensure consistent reflective target visibility. For vision-based systems, racking components may include high-contrast fiducial markers. The design of the aisle itself—its width, straightness, and end-of-aisle turning zones—is dictated by the AGU’s turning radius and safety sensors.

Load Interface Design: The point of interaction between the AGV’s lift mechanism and the rack is crucial. Narrow aisle pallet rack designs must have standardized, consistent heights and clearances for fork entry. Beams are often designed with a specific profile that allows for smooth, snag-free operation by robotic forks, which may have less tactile feedback than a human operator.

System Redundancy and Safety: Redundant navigation features within the narrow aisle pallet rack designs environment ensure operational continuity. Furthermore, safety zones, emergency stop corridors, and clear signaling protocols are physically baked into the layout of these high-density narrow aisle pallet rack designs to ensure safe coexistence with any human workers.

A case in point: A multinational pharmaceutical distributor in Thailand implemented AGV-ready narrow aisle pallet rack designs in their new high-bay warehouse. The racks were designed with integrated wire-guidance channels and featured beam levels calibrated to the exact lift heights of their fleet of unit-load AGVs. The result was a 99.99% system uptime and a 60% reduction in product handling time, proving that the right narrow aisle pallet rack designs are the backbone of reliable automation.

Forklift-Ready Designs: Bridging the Present and the Automated Future

While AGVs represent the cutting edge, the global reality is that forklifts—both manual and automated—will remain the workhorses of material handling for the foreseeable future, especially in markets with varying labor costs and automation adoption curves. Therefore, the most pragmatic and flexible narrow aisle pallet rack designs are engineered to be universally forklift-ready.

This means designing for compatibility with:

Traditional Man-Up Turret Trucks: These are the classic narrow aisle machines. Racks must have precise vertical beam spacing to allow the operator clear visibility and access, with special attention to top beam heights and back-to-back rack clearances.

Automated Guided Forklifts: These vehicles combine the load-handling capability of a forklift with the autonomous navigation of an AGV. Narrow aisle pallet rack designs for these systems must meet the dual requirements of structural robustness for heavy loads and the precision alignment needed for automated navigation.

Counterbalance Forklifts in Hybrid Systems: In facilities using a mix of wide and narrow aisles, some narrow aisle pallet rack designs may be accessed by standard counterbalance trucks. Here, design focuses on exceptional impact resistance and clear aisle demarcation.

The genius of expertly engineered forklift-ready narrow aisle pallet rack designs lies in their adaptability. A warehouse in Colombia, for example, might begin operations with a fleet of traditional reach trucks. By choosing forward-compatible narrow aisle pallet rack designs, they can seamlessly transition to automated forklifts in Phase 2, and perhaps integrate with AGVs for specific tasks in Phase 3—all without replacing the core storage infrastructure. This protects capital investment and provides unparalleled strategic flexibility.

Regional Adaptations: Tailoring Narrow Aisle Pallet Rack Designs for Global Challenges

A one-size-fits-all approach is a recipe for failure in international logistics. Superior narrow aisle pallet rack designs are meticulously adapted to the unique environmental, economic, and operational conditions of their deployment region.

Southeast Asia – Humidity and Seismic Activity: In tropical climates like Indonesia and the Philippines, narrow aisle pallet rack designs must combat persistent high humidity and corrosion. This necessitates hot-dip galvanized steel finishes, often with additional powder coatings. In seismically active zones, these narrow aisle pallet rack designs incorporate specialized seismic bracing and connection details that allow for controlled flex and energy dissipation, adhering to strict local building codes.

The Middle East – Dust, Heat, and Sand: Warehouses in Saudi Arabia or the UAE face extreme heat, abrasive sandstorms, and wide temperature fluctuations. Narrow aisle pallet rack designs here utilize special alloy steels with higher heat tolerance, advanced sealing techniques to protect bearings in mobile racking components, and dust-proofing measures on critical connection points.

Africa – Infrastructure Variability and Cost Sensitivity: Across diverse African markets, challenges range from unreliable power grids to a need for exceptionally durable, low-maintenance solutions. Narrow aisle pallet rack designs for these markets might prioritize modularity for easy repair, incorporate designs that facilitate natural ventilation to reduce cooling needs, and be compatible with hybrid power systems for automated equipment.

Latin America – Mixed-Use Facilities and Volatile Markets: The dynamic economies of Brazil, Mexico, and Chile often require warehouses to handle diverse product types. Versatile narrow aisle pallet rack designs that can easily adjust beam levels, accommodate various pallet sizes (common in regional trade), and support high weight capacities for industrial goods are essential. Durability against potential humidity in coastal areas is also a key design factor.

Understanding these nuances is what separates a global supplier from a local vendor. It ensures that the installed narrow aisle pallet rack designs deliver not just promised density, but also longevity and reliability in their specific operating context.

The Technology Ecosystem: Software, Sensors, and Smart Racking

The modern incarnation of narrow aisle pallet rack designs exists within a rich technology ecosystem. The physical rack is the skeleton, but the nervous system is digital.

Warehouse Management System (WMS) Integration: Every location within the narrow aisle pallet rack designs is a unique identifier in the WMS. Advanced systems use the WMS to direct equipment to the optimal storage location based on turnover (using Golden Zone strategies), expiration dates, or picking sequences. The efficiency of the narrow aisle pallet rack designs is multiplied by the intelligence of the software controlling it.

IoT and Condition Monitoring: Proactive narrow aisle pallet rack designs can be equipped with IoT sensors. These monitor load weight on beams to prevent overloading, detect impacts through vibration sensors, and even monitor structural alignment. This data feeds into a Condition-Based Maintenance (CBM) program, transforming maintenance from a reactive cost center to a predictive, planning function.

Digital Twin and Simulation: Before installation, advanced providers use simulation software to create a digital twin of the proposed narrow aisle pallet rack designs within the virtual warehouse. This allows for optimization of traffic flow, identification of potential bottlenecks, and accurate prediction of throughput—de-risking the entire investment before a single beam is erected.

The Implementation Roadmap: From Concept to Operational Excellence

Successfully deploying high-performance narrow aisle pallet rack designs is a phased, disciplined process.

Discovery and Data Analysis: It begins with a deep analysis of SKU profiles, pallet specifications, inventory turnover rates (ABC analysis), and growth projections. Floor condition surveys and building structural assessments are critical.

Conceptual Design and Simulation: Multiple narrow aisle pallet rack designs layouts are modeled, comparing storage capacity, equipment paths, and projected efficiency gains. This stage aligns all stakeholders on the operational vision.

Detailed Engineering and Specification: This is where the generic becomes specific. Every component of the narrow aisle pallet rack designs is specified—steel grade, finish, bolt type, safety accessory—creating a comprehensive bill of materials and installation guide.

Professional Installation and Commissioning: Certified installation crews follow precise procedures, using laser levels and alignment tools to ensure the narrow aisle pallet rack designs meet the engineered tolerances. Load testing and system integration sign-off are final steps.

Training and Ongoing Support: Operators and maintenance staff receive thorough training on the unique aspects of the new narrow aisle pallet rack designs, including safety protocols, daily inspections, and basic troubleshooting. A clear support and spare parts agreement ensures long-term performance.

Conclusion: Building the Foundation for a Dominant Logistics Operation

In the final analysis, the choice of storage infrastructure is one of the most consequential decisions a logistics or warehouse manager can make. It is a long-term capital investment that directly dictates daily operational ceilings for speed, cost, and scalability. Specifying advanced, automation-ready narrow aisle pallet rack designs is not merely a purchasing decision; it is a strategic commitment to building a faster, denser, smarter, and more resilient operation.

For businesses targeting leadership in the competitive landscapes of Southeast Asia, the Middle East, Africa, and Latin America, partnering with an expert who understands the intricate interplay between steel, software, and regional realities is paramount. The ideal partner doesn’t just sell narrow aisle pallet rack designs; they engineer integrated storage solutions that serve as a perpetual platform for efficiency, ready to embrace both the forklifts of today and the robotic systems of tomorrow.

Frequently Asked Questions (FAQs)

1. How do we calculate the exact ROI for implementing new narrow aisle pallet rack designs in our existing facility?

A precise ROI calculation requires a detailed analysis of current costs (real estate per square meter, labor hours for picking/replenishment, energy consumption) versus the projected state after implementing new narrow aisle pallet rack designs. Key metrics include the increased storage capacity (allowing for deferred expansion or subletting), the reduction in travel time for operators, and lower utility costs per stored pallet. Reputable providers offer feasibility studies that model these financial outcomes based on your specific operational data.

2. Can our existing concrete floor support the heavier point loads of a high-density narrow aisle pallet rack design system?

This is a critical structural question. While narrow aisle pallet rack designs distribute weight efficiently, their high-density nature often results in greater point loads on the floor. A professional site assessment always includes a floor survey and core sampling if needed. In many cases, existing floors are sufficient, but for older facilities or very high racks, reinforcement or the use of base plates to distribute the load may be necessary. This assessment is a non-negotiable part of responsible narrow aisle pallet rack designs engineering.

3. What fire protection considerations are unique to high-density narrow aisle pallet rack designs?

High-density storage presents specific fire safety challenges, as traditional sprinkler systems may be less effective in tightly packed aisles. Modern narrow aisle pallet rack designs often integrate with specialized fire protection solutions, such as in-rack sprinkler heads installed at vertical intervals within the rack structure itself. Compliance with local fire codes (like NFPA or regional equivalents) is essential, and the layout of the narrow aisle pallet rack designs must be planned in conjunction with the fire protection engineer.

4. How does the lead time and procurement process for custom narrow aisle pallet rack designs work for an international project, say in Africa?

International projects require meticulous logistics planning. The process involves finalizing engineered drawings, manufacturing the components to specification (often with region-specific finishes), and then managing the international freight, customs clearance, and last-mile delivery. Experienced global suppliers have established supply chains and local partners to manage this process smoothly. Lead times can vary from 8 to 16 weeks from order to site delivery, depending on complexity and destination.

5. Are there sustainable or “green” options when specifying narrow aisle pallet rack designs?

Absolutely. The sustainability of narrow aisle pallet rack designs is multi-faceted. Firstly, the steel used can include a high percentage of recycled content. Secondly, the efficiency gains—using less building space and energy—have a direct positive environmental impact. Furthermore, manufacturers are increasingly using environmentally friendly powder coating processes. The longest-lasting, most adaptable narrow aisle pallet rack designs are inherently sustainable by avoiding premature replacement and the waste associated with it.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com