📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Definitive Guide to Pharmaceutical-Grade Narrow Aisle Racking: Engineering Storage Density for Compliance and Growth

In the intricate ecosystem of pharmaceutical supply chains, the warehouse is far more than a static repository. It is a dynamic, controlled node where product integrity, regulatory destiny, and operational profitability converge. For logistics directors, warehouse managers, and strategic planners across Southeast Asia, the Middle East, Africa, and Latin America, the challenge is universal: accommodating soaring SKU counts and stringent compliance mandates within finite, often exorbitantly expensive, real estate. The conventional answer—expanding a facility’s footprint—is frequently a capital-intensive and logistically fraught endeavor.

A more intelligent, transformative solution lies in looking upward and inward, leveraging a meticulously engineered narrow aisle racking for pharma storage system. This comprehensive examination delves beyond superficial specifications, exploring how a purpose-built narrow aisle racking for pharma installation, particularly when integrated with automation, redefines storage paradigms, safeguards product quality, and delivers an undeniable return on investment for modern pharmaceutical enterprises.

Understanding the Core Imperative: Why Standard Racking Fails Pharma

The limitations of traditional wide-aisle selective pallet racking in a pharmaceutical context are profound and multifaceted. These systems, designed for general industry, inherently prioritize forklift maneuverability over volumetric efficiency. In a GMP-governated environment, this design philosophy introduces a cascade of operational vulnerabilities.

Primarily, the spatial inefficiency is staggering. Aisles stretching 3 to 3.5 meters wide can consume up to 50% of a facility’s total cubic volume. For a pharmaceutical company operating a cold chain storage facility, this translates to paying enormous energy costs to cool empty airspace. The financial logic is unsustainable. Furthermore, the reliance on human-operated forklifts in these wide aisles introduces significant variables incompatible with pharmaceutical rigor.

The risk of pallet impact—damaging both the racking structure and, critically, the product itself—is ever-present. Inconsistent handling speeds and extended search times for specific lots or batches compromise temperature stability in climate-controlled zones and reduce overall throughput. For operations in regions facing infrastructural challenges, such as power fluctuations or humidity extremes, these inefficiencies are magnified, eroding margins and elevating risk.

The adoption of a specialized narrow aisle racking for pharma systems addresses these shortcomings at a foundational level. By radically reducing aisle widths—often to between 1.5 and 1.8 meters—the system immediately reclaims vast swathes of floor space for productive storage. However, the true sophistication of a narrow aisle racking for pharma solution lies not merely in the dimensional change but in the holistic engineering that supports it, transforming reclaimed space into a high-performance, compliant storage engine.

The Anatomy of a Pharma-Centric Narrow Aisle Racking System

Distinguishing a pharmaceutical-grade system from a standard industrial narrow aisle racking setup requires an understanding of several non-negotiable design and material principles. The operating environment dictates a higher standard.

Structural Integrity and Seismic Resilience:

Pharmaceutical loads are dense. Pallets of glass vials, bottled liquids, or raw materials can approach maximum weight capacities. A robust narrow aisle racking for pharma structure is calculated with elevated safety factors, often adhering to rigorous international standards like FEM 10.2.02 or comparable local codes. This is particularly crucial for markets in seismically active zones, such as parts of Southeast Asia and Latin America.

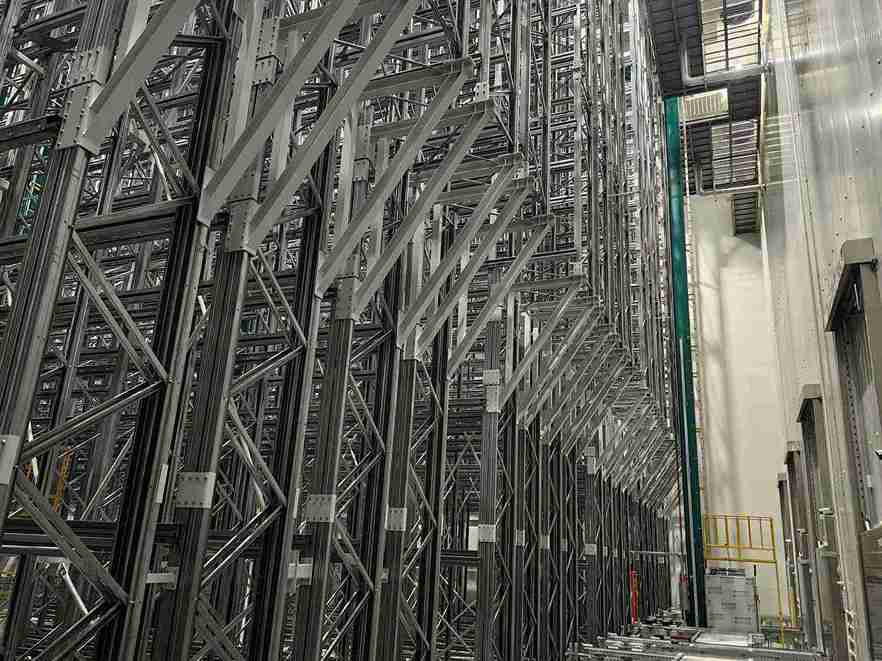

Engineering for seismic events involves dynamic load calculations, ensuring the system maintains its integrity during ground movement, protecting both invaluable inventory and personnel. The upright frames in a true narrow aisle racking for pharma application are fabricated from high-tensile, consistently certified steel, with laser-cut precision ensuring the tolerances necessary for seamless automation integration.

Corrosion Resistance: A GMP Mandate, Not an Option:

The environmental conditions within a pharmaceutical warehouse are aggressively corrosive. Cold chain storage areas undergo constant condensation cycles and routine wash-downs with cleaning agents as part of validation protocols. Ambient storage for raw materials may face exposure to powders or chemicals. A standard industrial paint finish is wholly inadequate. A certified narrow aisle racking for pharma system employs a multi-stage defense. The steel undergoes a thorough pretreatment (phosphating) before receiving a high-thickness, epoxy-polyester hybrid powder coating, typically between 80-120 microns.

For extreme environments, such as coastal regions in the Middle East or high-humidity areas in Africa, a hot-dip galvanized undercoat is specified prior to powder coating. This creates a monolithic barrier that resists chipping, peeling, and rust formation—preventing particulate contamination that would directly violate GMP clean area standards. This level of finish is a hallmark of dedicated narrow aisle racking for pharma products.

Automation-Ready Design Precision:

The defining characteristic of a modern narrow aisle racking for pharma system is its symbiosis with automated storage and retrieval systems (AS/RS). The racking is not a passive structure but an active component of the automation grid. Upright frames are manufactured with millimetric precision to ensure perfect vertical and horizontal alignment over long runs. This is critical because an automated stacker crane or shuttle operates on a digital map; even minor deviations can cause system faults.

Reinforced connector profiles and integrated mounting points for guidance rails are engineered into the structure from the outset. When specifying narrow aisle racking for pharma, forward-thinking operators ensure the design is “automation-ready,” even if phased implementation is planned, safeguarding future scalability.

The Automation Synergy: Transforming Density into Intelligent Throughput

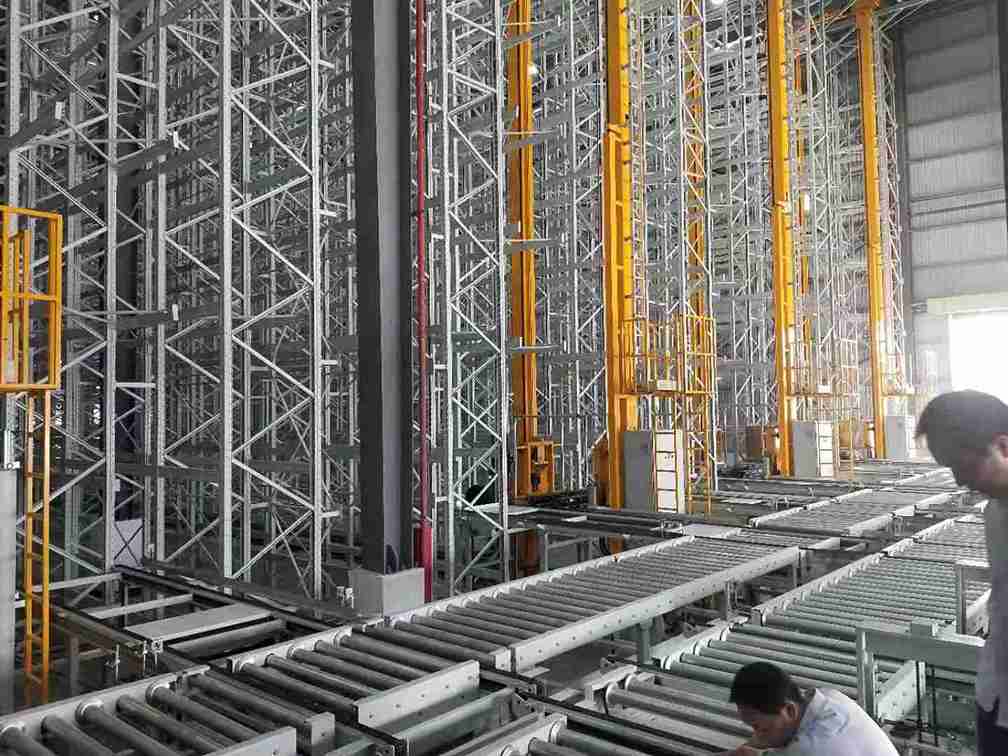

Implementing a narrow aisle racking for pharma system without considering automation is to realize only half the potential. The narrow aisles themselves are inaccessible to traditional forklifts, necessitating specialized equipment. This necessity births opportunity: the integration of deterministic, software-driven machinery that operates with unerring precision.

The Storage Retrieval Workhorses:

Two primary technologies interface with narrow aisle racking for pharma systems. The first is the Stacker Crane (AS/RS), the workhorse for high-throughput, high-density applications. These cranes run on floor- and ceiling-mounted rails, operating within the tight confines of the narrow aisle racking for pharma bays. They combine horizontal and vertical movement to access any pallet location with pinpoint accuracy. For cold chain storage, these cranes are built with cold-rated components—specialized lubricants, drives, and sensors—allowing reliable operation at temperatures as low as -30°C.

Their speed and pre-programmed retrieval paths minimize the time storage doors are open, drastically reducing thermal perturbation and energy waste. The second technology is the Robotic Pallet Shuttle, ideal for ultra-high-density, multi-deep storage within a single level of the narrow aisle racking for pharma system. A shuttle device travels inside the racking structure, managing the front-to-back movement of pallets, enabling incredible storage consolidation for slow and medium-turnover items, a common scenario in ambient store warehouses for packaged goods.

The Central Nervous System: WMS Integration and Intelligence:

The physical hardware is orchestrated by a sophisticated Warehouse Management System (WMS). This integration is what transforms a narrow aisle racking for pharma complex from a static archive into a dynamic fulfillment engine. The WMS enforces critical pharmaceutical logistics rules automatically: First-Expired, First-Out (FEFO) and lot tracking are managed by the software, directing the cranes to retrieve specific batches based on expiry data. It provides real-time, pallet-level inventory visibility and automates putaway logic, determining the optimal location based on product turnover, weight, and compatibility. This intelligence layer is essential for maximizing the efficiency gains promised by the narrow aisle racking for pharma infrastructure.

The Flexible Connectors: AGVs and Driverless Vehicles:

While stacker cranes master the dense storage lanes, the logistics flow is completed by Automated Guided Vehicles (AGVs) or driverless forklifts. These flexible mobile robots transport pallets between the narrow aisle racking for pharma system’s pickup/drop-off points and other zones—receiving, staging, packing, or shipping. Implementing laser-guided or natural feature navigation AGVs creates a seamless, continuous material flow that connects the high-density storage core to the wider warehouse operations, rounding out a fully automated narrow aisle racking for pharma ecosystem.

Quantifying the Advantage: The 80%+ Density Increase Demystified

The claim of an 80% or greater increase in storage density is not hyperbolic; it is a predictable outcome of applied engineering physics. Consider a theoretical warehouse module of 50 meters in length and 30 meters in width.

Baseline (Conventional Racking): Utilizing 3.2-meter aisles for counterbalance forklifts, with racking height limited to what a forklift can safely service (e.g., 10 meters), the module might hold approximately 3,000 pallet positions.

Optimized (Automated Narrow Aisle Racking for Pharma): Aisle width is reduced to 1.6 meters for a stacker crane. The racking height can be extended to the building’s clear eave height (e.g., 15 meters), as the crane is not limited by a lifting cab. Furthermore, the system can be configured for double-deep storage or incorporate shuttle systems within a level. The same physical footprint can now accommodate over 5,400 pallet positions.

This represents an 80% gain. The exact multiplier is influenced by site-specific parameters—building height, pallet dimensions, and required access policies—but a properly configured narrow aisle racking for pharma system consistently delivers transformative density improvements. For brownfield sites being retrofitted, gains of 50-70% are routinely achievable without expanding the building envelope.

The Holistic ROI: Gains Beyond Mere Square Meters

The financial justification for investing in a sophisticated narrow aisle racking for pharma system extends far beyond the value of the reclaimed air space. A comprehensive Total Cost of Ownership (TCO) analysis reveals multi-faceted savings.

Labor Productivity & Safety: A single automated narrow aisle racking for pharma system can replace multiple shifts of forklift operators, reducing direct labor costs, associated training, and management overhead. It also virtually eliminates accidents related to manual pallet handling, improving safety metrics and potentially lowering insurance premiums.

Energy Optimization (Critical for Cold Chain): In temperature-controlled environments, the high-density nature of a narrow aisle racking for pharma system means a smaller overall volume requires refrigeration. Coupled with the rapid, minimized door-open cycles of automated retrieval, facilities report energy consumption reductions of 30-40% for their cold storage operations—a direct and substantial operational saving.

Inventory Accuracy & Loss Prevention: Automated systems governed by a WMS achieve inventory accuracy rates exceeding 99.99%. The elimination of manual handling reduces product damage from impacts to near zero. More importantly, the enforced FEFO compliance ensures that costly expired goods write-offs are minimized, protecting both revenue and patient safety.

Scalability and Future-Proofing: Expansion of storage capacity often becomes a matter of utilizing more of the existing cubic airspace or increasing the depth configuration within the narrow aisle racking for pharma system, deferring or eliminating the need for costly new construction.

Compliance by Design: Building Validation into the Framework

For pharmaceutical companies, regulatory compliance is not a feature; it is the foundational license to operate. A well-executed narrow aisle racking for pharma project is engineered to facilitate and simplify the validation process (IQ/OQ/PQ).

Design Documentation (DQ/IQ): Reputable suppliers provide a complete dossier of design specifications, material certificates, welding procedures, and coating reports. This traceability is essential for Installation Qualification.

Cleanability and Hygiene: The smooth, high-quality finishes specified for narrow aisle racking for pharma systems, along with coved corners and minimized horizontal surfaces, are designed for easy cleaning and prevent the accumulation of dust or contaminants.

Unassailable Audit Trails: The integrated WMS and control software provide an immutable electronic log of every material movement, including timestamp, user (system login), batch/lot number, and location. This digital pedigree satisfies the strictest requirements for data integrity from regulators like the FDA, EMA, and regional health authorities, making audits a process of report generation rather than forensic investigation.

Regional Implementation Nuances: A Tailored Approach for Global Markets

The successful deployment of a narrow aisle racking for pharma system in Jakarta, Jeddah, Johannesburg, or Guadalajara requires more than a one-size-fits-all blueprint. Expert suppliers demonstrate deep regional awareness.

Southeast Asia & Coastal Africa (High Humidity/Heat): Emphasis is placed on the highest-grade corrosion protection for the narrow aisle racking for pharma structure. Electrical components for automation are selected for high ambient temperature tolerance and moisture resistance. System designs often incorporate graceful shutdown and recovery protocols for areas with less stable power grids.

Middle East (Dust, High Ambient Temperatures): Sealed bearings and ingress-protected (IP-rated) components are standard for automation equipment. Cooling systems for control cabinets are robustly sized. The structural design of the narrow aisle racking for pharma system accounts for significant thermal expansion and contraction.

Latin America (Seismic & Diverse Regulations): Engineering teams must be proficient in local seismic codes (e.g., NCh433 in Chile, CFE in Mexico). A nuanced understanding of varying national health authority expectations is critical. Local partner networks for service and support are vital for long-term system health.

The Strategic Pathway: From Feasibility to Go-Live

Engaging with a specialist to implement a narrow aisle racking for pharma solution is a collaborative, phased journey.

Deep-Dive Storage Audit & Simulation: The process begins with a granular analysis of SKU profiles, turnover velocities (ABC analysis), growth projections, and process flows. Using advanced simulation software, designers can model the proposed narrow aisle racking for pharma system’s performance under peak demand scenarios, optimizing the design virtually before commitment.

Phased Engineering & Collaborative Design: Detailed layout designs, structural calculations, and automation specifications are developed in iterative stages, with close consultation from the client’s engineering, validation, and operations teams.

Manufacturing & Pre-Assembly Quality Control: Components for the narrow aisle racking for pharma system are manufactured under controlled conditions, with rigorous quality checks at each stage. Pre-assembly of critical sections may occur to verify fit and function.

Supervised Installation & Commissioning: Certified installation teams, often supervised by expatriate engineers with global project experience, execute the build. Commissioning involves meticulous testing of every mechanical and software function against the predefined operational protocols.

Knowledge Transfer & Long-Term Partnership: Comprehensive training for maintenance and operations staff is provided. The relationship transitions to a long-term service and support agreement, often supported by remote monitoring technology that allows for proactive maintenance, ensuring the narrow aisle racking for pharma system delivers decade-spanning performance.

Conclusion: The Storage Imperative for a Competitive Future

The evolution from manual, space-inefficient warehousing to an automated, high-density narrow aisle racking for pharma ecosystem represents a strategic inflection point for pharmaceutical logistics. It is an investment that transcends mere storage, morphing into a core competitive asset that ensures regulatory adherence, guarantees product integrity, unlocks latent capacity, and delivers a compelling, calculable financial return. In the fast-growing yet competitive markets of the global south, where operational excellence and agility determine market leadership, adopting this technology is no longer a speculative luxury but an operational imperative.

The critical question for industry leaders is not whether they can afford to upgrade to a dedicated narrow aisle racking for pharma solution, but whether they can afford the escalating costs—financial, regulatory, and competitive—of persisting with outdated, inefficient storage methodologies. The journey toward optimized storage begins with a clear-eyed evaluation of current constraints and a vision for a more efficient, compliant, and profitable future.

Frequently Asked Questions (FAQs)

Q1: How does the fire protection and sprinkler system design integrate with a high-bay, high-density narrow aisle racking for pharma system?

A: This is a critical safety consideration. Standard ceiling-mounted sprinklers are ineffective in dense storage exceeding 12 feet. An ESFR (Early Suppression, Fast Response) sprinkler system or an in-rack sprinkler system is typically required for a narrow aisle racking for pharma installation. The racking layout and automation equipment must be designed in coordination with fire protection engineers to ensure adequate water distribution and coverage for every pallet position, complying with local building and fire codes (NFPA, FM Global, or regional equivalents). This integrated design is a standard part of a professional narrow aisle racking for pharma project scope.

Q2: What are the key differences in selecting a narrow aisle racking for pharma system for a bulk raw material warehouse versus a finished goods distribution center?

A: The operational focus drives the configuration. For raw material narrow aisle racking for pharma stores, the emphasis is often on high-density, lower-frequency access. Configurations like double-deep or drive-in racking might be suitable for stable, homogenous materials. For finished goods distribution, high throughput and direct access to every SKU for order picking are paramount. Here, single-deep narrow aisle racking for pharma linked to a high-speed AS/RS and a goods-to-person picking system is typical. The WMS logic also differs, focusing more on FEFO for raw materials and multi-order batch picking efficiency for distribution.

Q3: Can an existing warehouse with a relatively low clear height (e.g., 8 meters) still benefit from a narrow aisle racking for pharma solution, or is it only for high-bay buildings?

A: Absolutely. While the most dramatic density gains are achieved by leveraging vertical space, a narrow aisle racking for pharma system in a lower-clear-height building still delivers substantial benefits. The primary gain comes from reclaiming the floor area lost to wide aisles. Even at 8 meters, converting from 3m aisles to 1.6m aisles can increase pallet positions by 30-50%. It also paves the way for automation, improving accuracy and labor efficiency. The system design is simply optimized for the available cube.

Q4: How does the system handle damaged or non-standard pallets that could potentially jam an automated crane or shuttle in the narrow aisle racking for pharma structure?

A: Robust systems incorporate multiple safeguards. First, inbound pallet quality control is essential; the WMS can mandate a pallet dimension check at receiving. Second, the automation equipment is fitted with sensitive torque sensors and obstacle detection lasers. If a pallet encounters abnormal resistance during storage, the crane will abort the cycle, alert operators, and place the pallet in a designated quarantine location for manual inspection. The design of the narrow aisle racking for pharma system itself includes smooth, guiding surfaces and generous entry profiles to minimize hang-ups.

Q5: For a multi-national pharma company building a new greenfield facility, at what stage in the architectural design process should the narrow aisle racking for pharma and automation supplier be involved?

A: The ideal time is during the conceptual or preliminary design phase, alongside the civil and MEP (Mechanical, Electrical, Plumbing) engineers. Early involvement of the narrow aisle racking for pharma specialist ensures the building’s column grid, clear heights, door placements, and floor flatness specifications are optimized for the storage system, avoiding costly redesigns later. They can also provide critical load data for the structural frame and inform the design of the electrical substation and HVAC requirements, especially for cold chain storage areas, leading to a more integrated and cost-effective overall facility design.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com