📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Safe & Space-Saving: Expert Narrow Aisle Racking Solutions for Emerging Markets

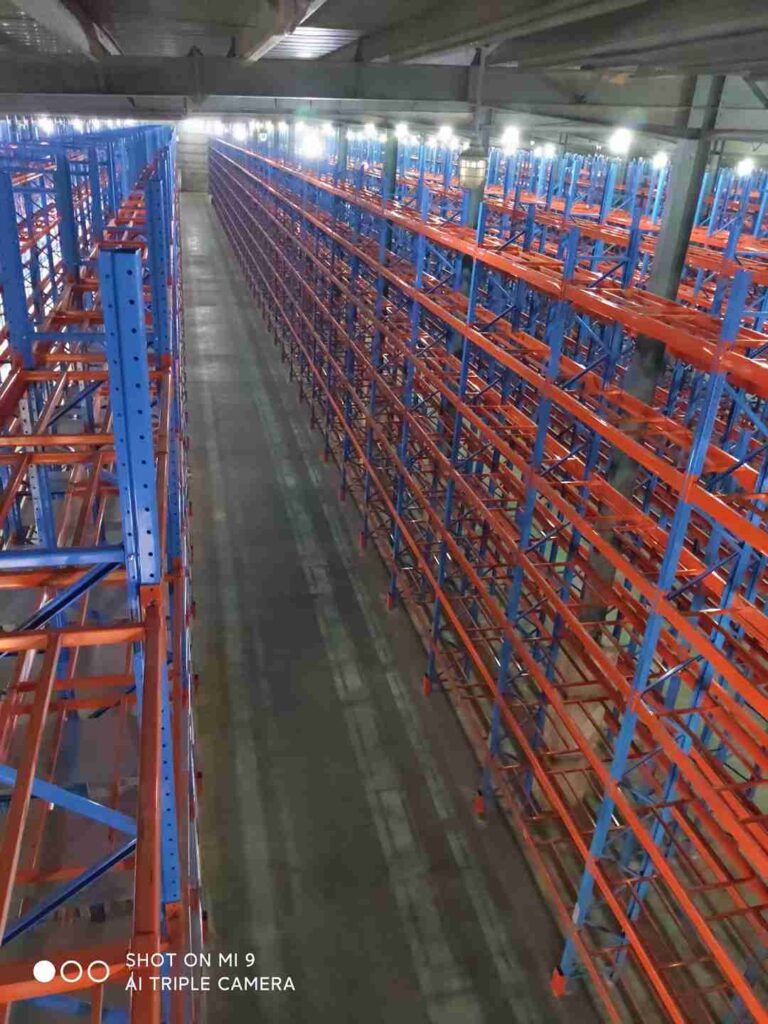

In the bustling industrial corridors of Jakarta, the sprawling logistics parks of Dubai, and the rapidly expanding manufacturing hubs of Mexico, a silent revolution in warehouse optimization is underway. At the heart of this transformation is a sophisticated storage methodology: high density narrow aisle racking. This system is not merely a piece of equipment; it is a foundational re-engineering of warehouse space, a strategic response to the unique pressures of growth in emerging economies.

For logistics directors, warehouse managers, and business owners navigating the challenges of soaring real estate costs, volatile supply chains, and escalating customer expectations, understanding and implementing the right high density narrow aisle racking solution is a critical determinant of competitive advantage. This definitive resource delves beyond superficial specifications, offering a masterclass in the engineering principles, operational nuances, and strategic integration of these systems, specifically tailored for the dynamic conditions of Southeast Asia, the Middle East, Africa, and Latin America.

The universal challenge is one of cubic efficiency. Traditional warehouses with wide aisles dedicate an unsustainable portion of their footprint—often exceeding 50%—to non-revenue generating space. A high density narrow aisle racking system directly attacks this inefficiency. By meticulously reducing forklift operating aisles to widths between 1.6 and 2.0 meters, it reclaims this lost area for storage.

However, the true genius of a well-executed high density narrow aisle racking design lies in its synergy with vertical space. When combined with high-reach or Very Narrow Aisle (VNA) forklifts, it allows facilities to exploit their full clear height, creating a dramatic multiplication of available pallet positions. The result is a potential increase in storage capacity of 40% to 60% within the same four walls, deferring or eliminating the need for costly facility expansion.

Yet, in emerging markets, the decision to adopt high density narrow aisle racking carries additional layers of consideration. Success hinges not on the racking alone, but on a holistic ecosystem encompassing unparalleled safety protocols, adaptability to local environmental and operational conditions, and a forward-looking design that accommodates future automation. This article explores why partnering with an expert who possesses deep regional experience is not a luxury, but a necessity for ensuring that a high density narrow aisle racking investment delivers its promised return safely, reliably, and durably.

The Technical Underpinnings of Superior Density

Architectural Principles of Space Reclamation

The core proposition of any high density narrow aisle racking system is architectural in nature. It redefines the warehouse layout from a “road network” model to a “skyscraper” model. In a standard selective racking layout, wide aisles function like major highways, allowing for easy turning and maneuvering of counterbalance forklifts but consuming vast tracts of prime space. A high density narrow aisle racking configuration, in contrast, functions like a densely packed city block with efficient, single-directional streets. This shift is enabled by a specialized class of material handling equipment: narrow aisle forklifts, which operate with greater precision and are often guided within the aisle.

The design process for an optimal high density narrow aisle racking layout is a complex exercise in spatial algorithm. It begins with a meticulous analysis of the inventory profile—pallet dimensions, weight, turnover velocity (ABC classification), and future growth projections. Using advanced warehouse simulation software, engineers model various configurations to achieve the perfect equilibrium between storage density and operational throughput.

The choice between single-deep and double-deep high density narrow aisle racking is a classic example of this trade-off. Single-deep racks offer direct access to every pallet, maximizing selectivity for high-turnover SKUs. Double-deep configurations, which require specialized forklift attachments, effectively halve the number of aisles, pushing density even higher but introducing a Last-In-First-Out (LIFO) access pattern suitable for medium-slow moving goods. An expert designer will often propose a hybrid layout, strategically placing each type to match the specific flow of goods within a facility.

Material Science and Structural Integrity

The structural demands on a high density narrow aisle racking system are significantly greater than on conventional racking. Not only must it support substantial loads at greater heights, but it must also withstand the inevitable dynamic forces of daily operation in a constrained space. The quality of materials and manufacturing is paramount.

Premium high density narrow aisle racking is fabricated from high-tensile, cold-rolled steel. Upright frames are typically designed with open-back “C” or “L” profiles for standard applications, or with robust box-column sections for very high bays or seismic zones common in certain geographies like parts of Latin America and Southeast Asia. The steel is protected by a multi-stage pretreatment and powder-coating process, crucial for resisting the corrosive effects of high humidity in tropical climates or chemical exposure in industrial settings. The coating thickness and quality are non-negotiable specifications for longevity.

The beam-to-upright connection is the critical safety junction in any racking system. In a high density narrow aisle racking environment, where forklift alignment is more challenging, the risk of impact is heightened. Therefore, beams feature positive, mechanical locking systems—such as patented twin-tab designs or safety clips—that securely latch into the upright’s connector holes from the inside. This ensures that an external blow to the beam cannot dislodge it, preventing a potential cascade failure. Beam profiles themselves, whether step-beams or box-beams, are engineered for maximum strength-to-weight ratio and deflection control, ensuring pallets rest securely even under maximum load.

The Imperative of Safety: Engineering a “Forgiving” Environment

The reduced tolerances of a high density narrow aisle racking warehouse make a world-class safety philosophy non-optional. Safety must be engineered into the system’s DNA, not added as an afterthought. This involves a multi-faceted approach focusing on structural resilience, operator guidance, and procedural discipline.

Impact Protection and System Resilience

A pragmatic approach to safety acknowledges that impacts will occur. The goal of a professionally designed high density narrow aisle racking system is to localize damage and prevent catastrophic collapse. This is achieved through a suite of integrated protective components:

Heavy-Duty Column Guards: These are thick-walled steel shields bolted to the front face of uprights at critical heights (typically 6-24 inches from the floor). They are designed to absorb the kinetic energy of a forklift mast or load, protecting the structural integrity of the upright itself.

Aisle Barrier Rails: Running the length of the aisle at pallet beam height, these continuous rails prevent a forklift’s forks or the pallet load from accidentally penetrating the racking bay adjacent to the aisle, safeguarding both the product and the rack structure.

Reinforced Footplates and Floor Anchorage: Uprights are secured to the floor with high-grade anchor bolts, sized and spaced according to load calculations and local seismic codes. In high-traffic zones or on softer floors, oversized footplates distribute the load more effectively and resist uplift forces.

Wire Mesh Decking and Pallet Supports: These prevent pallets or individual cartons from being accidentally pushed off the rear of the beam, a common occurrence in tight spaces. They also provide a secondary containment layer for safety.

Guidance and Visibility: Enabling Operator Precision

Human error is mitigated by designing an environment that guides correct behavior. In a high density narrow aisle racking system, this principle is paramount.

Aisle Guidance Technology: This is the cornerstone of safe, efficient narrow aisle operation. Two primary systems are employed:

Wire Guidance: A low-voltage current passes through a wire embedded in a shallow channel in the concrete floor. A sensor on the forklift detects the electromagnetic field, allowing the vehicle’s steering to be automatically controlled within the aisle. This ensures perfect centering, eliminating lateral drift and drastically reducing rack strikes.

Laser Guidance: A laser transmitter on the forklift projects a line onto a reflective target tape installed on the racking or end frames. An on-board camera tracks this line to auto-steer the vehicle. Laser systems offer easier installation and reconfiguration than wire guidance.

Optimized Lighting: Poor lighting increases eye strain and operator error. A professional high density narrow aisle racking project plan includes an assessment of ambient and task lighting. Solutions range from high-output LED fixtures mounted on the racking itself to directional aisle lights that eliminate shadows at high lift heights.

Comprehensive Signage: Every upright should be clearly labeled with its bay location and maximum load capacity. Aisle identifiers, floor markings for traffic direction, and prominent warning signs at aisle entrances create a visual communication system that reinforces safe practices.

Synergy with Material Handling Equipment: An Integrated Ecosystem

A high density narrow aisle racking system cannot be specified in isolation. It is one half of a symbiotic partnership with the material handling equipment (MHE). The choice of MHE dictates the final aisle width, racking tolerances, and operational procedures.

High-Reach Forklifts: The most common partner for a high density narrow aisle racking system. These trucks operate in aisles from 1.8m to 2.0m wide and can lift to heights of 12-14 meters. They offer a balance of density, selectivity, and flexibility, as they can often transition from narrow aisles to wider receiving areas. They require skilled, certified operators.

Very Narrow Aisle (VNA) Trucks: For the ultimate in storage density, VNA trucks operate in aisles as tight as 1.5m to 1.7m and can service heights beyond 15 meters. They almost universally require a guidance system (wire or laser) and come in man-up (operator ascends with the load) or man-down (remote operation) configurations. The precision required for VNA operations demands exceptionally tight tolerances in the high density narrow aisle racking installation and floor flatness.

The Automation Bridge: A forward-thinking high density narrow aisle racking design actively paves the way for automation. By ensuring rigorous consistency in aisle width, vertical alignment, and rack face straightness, the infrastructure becomes “AGV-ready.” The same precise environment that guides a manned VNA truck can be navigated by an automated guided vehicle or a fully autonomous forklift. Provisions can be made in the initial design for the future installation of navigation targets, communication beacons, or integration points with automated conveyor systems, protecting the capital investment for years to come.

Implementation in Emerging Markets: Navigating Local Realities

Deploying a sophisticated high density narrow aisle racking solution in Hanoi, Durban, or Bogotá presents a set of unique challenges and opportunities that a supplier with only textbook experience may overlook.

Environmental Adaptations: In the humid climates of Southeast Asia, specifying a powder-coating with superior resistance to moisture and fungal growth is critical. In the dusty, arid conditions of the Middle East, designs might include considerations for dust accumulation on beams and in guide rail channels. In regions with less predictable power grids, system designs that allow for safe manual operation during outages provide essential operational resilience.

Infrastructure Assessment: A thorough site evaluation is more than a formality. It includes a professional floor flatness survey to DIN 15185 or equivalent standards. If the floor does not meet the stringent requirements for VNA operation (e.g., ±10mm over 10m), solutions like laser screeding or grinding must be factored into the project. Building clear heights, column spacing, and the capacity of roof structures to support potential mezzanines or top-tier loads must be rigorously verified.

Skills Development and Knowledge Transfer: The success of a high density narrow aisle racking system is as much about people as it is about steel. A superior implementation partner provides comprehensive, hands-on training not just for forklift operators, but for maintenance staff and warehouse managers. This includes daily inspection routines, damage assessment protocols, and basic load beam adjustment procedures. Building this local competency ensures the system’s longevity and safe operation.

Regulatory Navigation and Standards Compliance: While local regulations may vary, a reputable provider designs and installs systems to internationally recognized safety and design standards, such as those from the Federation Européenne de la Manutention (FEM) or the Rack Manufacturers Institute (RMI). This global benchmark ensures a baseline of safety and performance, often exceeding local minimum requirements.

The Strategic Pathway: From Assessment to Operational Excellence

Implementing a high density narrow aisle racking system is a strategic project that follows a logical, phased pathway:

Diagnostic Audit & Data Analysis: This phase involves deep collaboration. Experts analyze inventory data (SKU counts, dimensions, weight, turnover), current and forecasted throughput, and the physical characteristics of the building. The output is a clear picture of the opportunity and constraints.

Simulation & Custom Design: Using the audit data, engineers create multiple digital layout models. They run simulations to test different high density narrow aisle racking configurations (single vs. double deep, varying aisle widths) against projected activity cycles. This data-driven approach identifies the layout that maximizes both density and workflow efficiency before any metal is cut.

Precision Specification & Procurement: Every component is specified: upright frame gauge and depth, beam length and capacity, decking type, and all necessary safety accessories. For a high density narrow aisle racking system, even the quality and grade of anchor bolts are a specified item.

Professional Installation & Commissioning: Certified installation crews, using laser levels and alignment tools, erect the system with millimeter precision. This stage includes the installation of guidance systems, protective devices, and signage. Upon completion, a full load test and safety inspection are conducted.

Training, Handover, and Ongoing Support: The system is formally commissioned with the client’s team. Training is conducted, and all documentation—including as-built drawings, load plaques, and maintenance manuals—is transferred. A schedule for periodic professional inspections should be established.

Conclusion: The Foundational Investment for Competitive Logistics

For businesses in the world’s most dynamic growth markets, warehouse space is a strategic asset. Maximizing its utility is not an operational tweak but a core business strategy. A professionally engineered and implemented high density narrow aisle racking system represents one of the highest-return investments a logistics-dependent company can make. It defers massive capital expenditure on new facilities, reduces operational costs per pallet stored, enhances inventory control, and builds a resilient, scalable foundation for future growth.

However, the phrase “professionally engineered” cannot be overstated. The density, safety, and longevity of a high density narrow aisle racking installation are direct results of the expertise behind it. In the complex environments of emerging markets, where conditions challenge standard assumptions, partnering with a provider that combines global engineering excellence with deep regional implementation experience is the single most important factor for success. It is the difference between simply installing storage and fundamentally transforming warehouse performance for the next decade. The journey begins with a clear-eyed assessment of current space utilization and a vision for a smarter, denser, and safer operational future.

Frequently Asked Questions (FAQs)

Q1: How does the seismic activity in certain regions affect the design of a high density narrow aisle racking system?

Seismic activity necessitates a fundamentally different engineering approach for any storage system, especially tall, high density narrow aisle racking. In seismic zones, engineers perform specific calculations based on local seismic codes (e.g., IBC, Eurocode 8) to determine the lateral forces the racking must withstand. This results in specifications for heavier-duty upright frames (often box-column designs), increased use of horizontal bracing, specific tie-backs to the building structure, and stricter requirements for floor anchorage using seismic-grade bolts. A qualified provider will always conduct a seismic risk assessment as part of the initial site audit for a high density narrow aisle racking project.

Q2: Can a high density narrow aisle racking system be relocated or reconfigured if our needs change?

A significant advantage of a quality high density narrow aisle racking system is its modularity. While more complex to dismantle and reassemble than simple shelving, it can be reconfigured. Beams can be relocated to different upright levels, and entire bays can be moved, though this requires professional assistance to ensure structural integrity is maintained. Factors like the condition of the components and the compatibility of parts from different batches must be considered. During the initial design, discussing potential future layout changes with your supplier can lead to specifications that facilitate easier reconfiguration later.

Q3: What is the lead time typically involved from design to operational handover for a large-scale high density narrow aisle racking project?

Lead times vary significantly based on project scale, customization, and global supply chain conditions. A typical timeline for a comprehensive high density narrow aisle racking project might be: 2-4 weeks for detailed design and simulation; 6-10 weeks for manufacturing of custom components; 2-4 weeks for shipping (depending on origin and destination); and 3-6 weeks for on-site installation and commissioning. For a total turnkey project including floor work and MHE procurement, the timeline can extend from 6 to 9 months. A reputable provider gives a detailed, phased project schedule upfront.

Q4: How do you manage the risk of product damage in such tight aisles, especially with fragile goods?

Minimizing damage in a high density narrow aisle racking environment is addressed through system design, equipment choice, and training. Key strategies include: 1) Using adjustable, padded fork spreaders on the forklifts to handle non-standard or fragile pallets gently. 2) Specifying wire mesh or solid decking on the racking beams to prevent small items from falling. 3) Implementing strict speed limits and operational protocols within the aisles. 4) For extremely fragile goods, a hybrid approach might be used, where bulk is stored in high density narrow aisle racking, but a separate, slower pick area with different handling is used for order fulfillment.

Q5: What are the ongoing maintenance and inspection requirements for a high density narrow aisle racking system?

A rigorous inspection regime is vital for safety and longevity. This includes: Daily Visual Checks by operators for obvious damage or leaning. Weekly Formal Inspections by a supervisor, focusing on beam connections, anchor bolts, and guide rails. Annual Professional Inspections conducted by a qualified engineer from the supplier or a third party. This annual audit involves checking plumb, load beam lock engagement, upright column deformation using a “rack ding” gauge, and the condition of all safety devices. A maintenance log should be kept for all inspections and any repairs made. The provider should supply a detailed inspection checklist as part of the handover documentation for the high density narrow aisle racking system.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com