📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Strategic Mastery of Warehouse Cubics: The Definitive Guide to Narrow Aisle Space Utilization for Competitive Advantage in Growth Markets

For logistics operators and warehouse managers across Southeast Asia, the Middle East, Africa, and Latin America, the relentless pressure to do more within the same four walls is the defining operational challenge of this decade. The solution, repeatedly proven in thousands of facilities worldwide, is not merely a piece of equipment or a racking layout—it is a fundamental operational philosophy centered on narrow aisle space utilization. This comprehensive approach systematically re-engineers the storage cube to unlock dormant capacity, directly translating into superior profitability, scalability, and market responsiveness.

True mastery of narrow aisle space utilization involves a synergistic integration of precision-engineered storage structures, specialized material handling equipment, and intelligent software. It represents a move from passive storage to active, high-density inventory management. For markets characterized by rapid urbanization, rising land costs, and explosive growth in sectors like e-commerce and manufacturing, the strategic imperative to maximize every square and cubic meter has never been greater. This guide delves beyond basic concepts, offering a data-driven, implementation-focused blueprint for transforming warehouse operations through superior narrow aisle space utilization, positioning businesses not just to compete, but to lead.

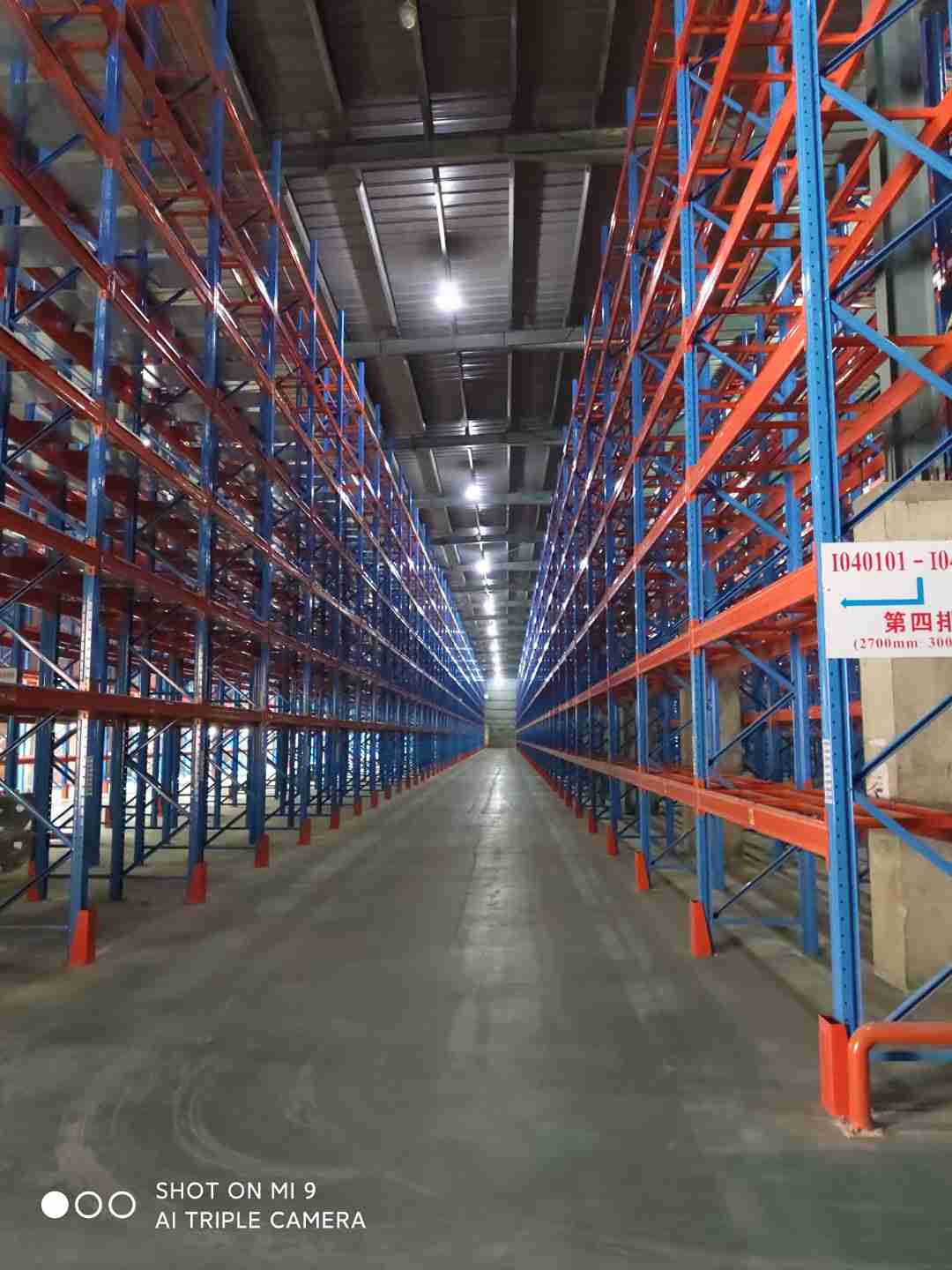

Warehouse transformation using bnarrow aisle space utilizationb racking systems

The High Cost of Empty Air: Quantifying the Inefficiency of Conventional Layouts

In a standard warehouse designed for counterbalance forklifts, the scene is familiar: vast swathes of precious floor area are dedicated not to storage, but to vehicle transit. Aisles typically spanning 3 to 3.5 meters in width can consume between 50% and 65% of the total facility footprint. This layout represents a monumental, ongoing capital drain. Companies are not just paying for this empty space in terms of rent or mortgage, construction, and taxes; they are also funding its lighting, climate control, and maintenance. In hot climates like the Middle East or tropical regions of Southeast Asia, cooling this void is exceptionally costly.

The inefficiency is volumetric, not just areal. Traditional racking, often limited to heights safe for standard forklifts, fails to capitalize on the full building cube. This results in a phenomenon known as “air stacking”—valuable vertical space is left unused. The operational consequences are severe: longer travel distances for order pickers, increased cycle times, higher energy consumption per pallet moved, and an inevitable ceiling on growth capacity.

When expansion is forced, it often means leasing additional satellite facilities, which fragments inventory, complicates management, and escalates costs. This operational model is unsustainable in competitive, fast-moving markets. The first step toward liberation is recognizing that conventional aisles are not pathways for productivity, but canyons of wasted potential. The deliberate pursuit of superior narrow aisle space utilization is, therefore, a direct attack on one of the largest fixed costs in the supply chain.

The Engineering Pillars of Maximum Density: Deconstructing the Narrow Aisle Ecosystem

Achieving exceptional narrow aisle space utilization requires moving beyond simply placing racks closer together. It demands a holistic system where every component is designed for precision, durability, and synergy.

1. The Structural Framework: Racking Engineered for Precision and Performance

The racking in a high-density system is the foundational element. It is fundamentally different from its wide-aisle counterpart.

Load Capacity and Dynamics: Beams and uprights are engineered for the specific load profiles and the dynamic forces introduced by narrow-aisle equipment, which operates with different stress vectors compared to a counterbalance forklift.

Tolerance and Alignment: The entire success of a narrow aisle space utilization project hinges on millimeter-perfect alignment. Racks must be installed with laser-guided precision to ensure consistent aisle widths. Even a slight deviation can cause operational delays, equipment damage, and safety hazards. Uprights are often designed with reinforced column sections to withstand occasional impacts and maintain alignment over time.

Height Optimization: Systems are designed to safely exploit the full clear height of the building, often up to 18 meters or more in a single-story construction. This vertical expansion is a critical multiplier in the narrow aisle space utilization equation.

2. The Material Handling Arsenal: Equipment Designed for the Tight Space

The aisle width is dictated by the equipment that navigates it. The evolution of this equipment is what makes modern narrow aisle space utilization possible.

Very Narrow Aisle (VNA) Turret Trucks: These are the stalwarts of high-density storage. In a “man-down” configuration, the operator compartment remains at floor level while the forks, mounted on a rotating turret, can store and retrieve pallets from either side without turning the vehicle. This allows aisles as narrow as 1.5 to 1.7 meters. Modern VNA trucks offer lift speeds exceeding 0.6 m/s, regenerative braking, and full integration with warehouse management systems (WMS).

Automated Guided Vehicles (AGVs) and Robotic Forklifts: This represents the pinnacle of efficiency and consistency in narrow aisle space utilization. Unmanned, these vehicles follow optimized paths 24/7, eliminating operator labor costs for mundane put-away and retrieval tasks. They operate with unerring accuracy, protecting racking and product. In markets facing a shortage of skilled forklift operators, or in harsh environments like cold storage, AGVs provide a reliable, high-productivity solution that dramatically enhances the return on investment from the dense storage infrastructure.

Guidance Systems: From reliable wire-in-floor guidance to advanced inertial or laser-based systems, this technology ensures the vehicle remains perfectly centered in the aisle. This precision is non-negotiable for protecting the racking investment and ensuring smooth operations.

3. The Cognitive Layer: Warehouse Intelligence Software

Hardware density without management intelligence leads to chaos. A sophisticated WMS is the brain that makes high narrow aisle space utilization viable.

Slotting Optimization: The WMS dynamically assigns stock to locations based on turnover rate (ABC analysis), product dimensions, and weight, ensuring fast-moving items are most accessible and space is used optimally.

Task Interleaving and Path Optimization: It sends intelligent work orders to equipment, combining tasks like a put-away followed immediately by a retrieval from the same aisle to minimize deadhead travel. For AGV fleets, it acts as a traffic control system, optimizing the flow of dozens of vehicles.

Inventory Integrity: In an environment with thousands of pallet locations in tight aisles, 99.9% inventory accuracy is mandatory. The WMS, often combined with barcode or RFID scanning, provides this control, ensuring no pallet is “lost” in the dense array.

The Financial Calculus: Modeling the ROI of Superior Space Utilization

The decision to invest in a narrow aisle space utilization strategy must be justified by compelling financials. The return is multifaceted and substantial.

Direct Capacity Gains: The most obvious benefit. By reducing aisle width from 3.5m to 1.6m and increasing storage height, a facility can typically achieve a 60-100% increase in pallet positions within the same footprint. This either defers or eliminates the need for costly expansion. In cities like Manila, Bangkok, or Dubai where industrial land is at a premium, this avoided capital expenditure is a massive financial win.

Operational Efficiency Savings: Density begets efficiency. Shorter, narrower aisles mean drastically reduced travel distances for order picking and stock replenishment. This translates into:

Lower Labor Costs: More picks per hour per operator.

Reduced Energy Consumption: Less distance traveled means lower power use for electric vehicles; a smaller footprint means less area to light and cool.

Higher Throughput: The facility can process more orders in the same time window, increasing revenue capacity.

Improved Accuracy and Safety: A more organized, system-directed operation reduces picking errors and product damage. The inherent design of VNA operations often enhances pedestrian safety by segregating man and machine. Fewer accidents mean lower insurance costs and less downtime.

A robust financial model for a narrow aisle space utilization project will factor in: (1) Capital cost of equipment and installation, (2) Savings from avoided expansion/leasing, (3) Annual operational savings (labor, energy, maintenance), (4) Increased revenue capacity, and (5) Intangible benefits like improved customer service. The payback period in high-throughput or high-rent environments is frequently under two years.

Tailored Implementation: Critical Success Factors for Emerging Markets

The flawless execution of a narrow aisle space utilization project in Jakarta requires different considerations than in Jeddah or Johannesburg. Local adaptation is key.

Infrastructure Adaptation:

Floor Flatness: This is the single most critical site preparation factor. VNA and AGV operations require floors with a tolerance often stricter than ±3mm over a 3-meter span. Partnering with local contractors who understand this requirement and can achieve it with laser screeding or grinding techniques is essential.

Power Quality and Climate: In regions with voltage fluctuations or high ambient temperatures, equipment must be specified with appropriate protection and cooling packages. AGV systems can be designed with opportunity charging stations to mitigate grid instability.

Workforce Development and Change Management:

Technology is only as good as the people who use and maintain it. A successful rollout includes:

Phased Training: Starting with theoretical training on system principles, followed by extensive hands-on simulator and practical training.

Local Champion Development: Identifying and upskilling local technicians for first-line maintenance builds long-term self-sufficiency.

Cultural Integration: Presenting the system as a tool that enhances job prestige and safety, rather than a threat, ensures smoother adoption.

The Automation Continuum: From Assisted to Fully Robotic Space Utilization

Narrow aisle space utilization is the perfect foundation for automation. Companies can progress along a continuum:

Manual VNA: Operator-driven turret trucks. Offers excellent density and a strong entry point.

AGV-Assisted VNA: Using automated vehicles for the predictable, repetitive movement of full pallets between receiving/staging and the racking face, while manned trucks handle the final storage/retrieval. This hybrid model offers a fantastic balance.

Fully Automated High-Density Storage: Integrating automated storage/retrieval machines (AS/RS) or robotic shuttles within the narrow aisle structure. This delivers the highest possible levels of narrow aisle space utilization, speed, and labor efficiency.

Designing the initial narrow aisle space utilization infrastructure to be “automation-ready”—with the right structural tolerances, data points, and aisle specifications—protects the initial investment and allows for seamless future upgrades.

Safety and Resilience: The Bedrock of Dense Operations

Intensifying narrow aisle space utilization must never compromise safety. The system design incorporates multiple layers of protection:

Rack Integrity: Robust column guards, end-of-aisle protectors, and high-visibility markings are standard. Regular rack inspection protocols are part of the operational manual.

Equipment Safeguards: VNA trucks and AGVs are equipped with multi-sensor safety systems (lasers, cameras, bumpers) that automatically slow or stop the vehicle if an obstacle is detected.

Operational Protocols: Strict pedestrian zoning, lock-out/tag-out procedures for rack maintenance, and comprehensive operator certification programs are enforced.

Disaster Resilience: In seismic zones or regions with specific wind-load requirements, the structural design of the racking is calculated accordingly, often involving specialized bracing and anchorage solutions.

A Phased Implementation Roadmap: From Audit to Optimization

A systematic approach ensures success and minimizes operational disruption:

Discovery and Data Audit: A deep analysis of SKU profiles, pallet data, historical and forecasted throughput, and growth plans.

Simulation and Design: Using advanced software to create 3D models and flow simulations of multiple layout options, predicting capacity and throughput gains before any steel is erected.

Site Preparation: Detailed guidance on floor preparation, lighting, network infrastructure, and any required building modifications.

Staged Installation: Careful sequencing to install racking, guidance systems, and commission equipment while keeping existing operations running, often in a phased “swim-lane” approach.

Commissioning and Knowledge Transfer: Full system testing under load and comprehensive training for all user levels.

Performance Management: Establishing KPIs (e.g., space use percentage, picks per hour, cost per pallet handled) and reviewing them regularly to identify further optimization opportunities.

Future-Proofing: The Smart Warehouse Evolution

A strategic narrow aisle space utilization project is the first major step toward a smart, connected warehouse. This infrastructure naturally supports:

IoT Integration: Sensors on racks can monitor load, impact, or environmental conditions. Sensors on vehicles enable predictive maintenance.

Digital Twin Creation: The precise 3D model of the layout becomes a living digital twin, used for ongoing planning, simulation, and workforce training.

Advanced Analytics: Data from the WMS and equipment generates insights for continuous improvement in slotting, labor planning, and inventory forecasting.

Conclusion: The Strategic Imperative for Market Leadership

In the dynamic commercial landscapes of Asia, Africa, the Middle East, and Latin America, logistics efficiency is a primary competitive weapon. Suboptimal storage is a hidden tax on growth, agility, and profitability. Mastering narrow aisle space utilization is not a tactical equipment purchase; it is a strategic overhaul of the storage paradigm. It is an investment that pays dividends not only in direct cost savings and capacity gains but also in enhanced operational resilience, scalability, and the ability to meet customer demands with unprecedented speed.

The journey requires a partner with global expertise, local execution capability, and a deep commitment to engineering-led solutions. It requires moving from seeing warehouse space as a simple container to viewing it as a complex, three-dimensional chessboard that can be optimized with intelligence and precision. For leaders ready to stop funding empty space and start capitalizing on every cubic meter of their asset, the path forward is clear: a dedicated, comprehensive strategy centered on world-class narrow aisle space utilization.

Frequently Asked Questions (FAQs)

1. How does the cost of a narrow aisle system compare to building a new warehouse expansion?

While the upfront capital investment for a high-density narrow aisle space utilization system is significant, it is almost always substantially lower than the cost of acquiring land, constructing a new building, and outfitting it with basic racking. The financial analysis must include the total cost of ownership over 10-15 years. The narrow aisle solution avoids ongoing costs for additional property taxes, insurance, utilities, and maintenance on a larger footprint. In most urban and peri-urban locations in growth markets, the ROI from maximizing existing space dramatically outperforms the expansion scenario.

2. Can existing wide-aisle racking be converted or retrofitted for narrow aisle operations?

In some limited cases, yes, but it is often not recommended. Existing racking may not have the load specifications, upright strength, or alignment precision required for narrow aisle equipment. The most reliable and safe approach is a purpose-designed system. However, a site audit can determine if certain components can be reused. Typically, the project involves a new structural system designed for the specific demands of high narrow aisle space utilization, ensuring decades of safe and productive operation.

3. What are the lead times for equipment like specialized VNA trucks or AGVs in these regions?

Lead times vary by manufacturer and model complexity. For popular VNA truck models, standard lead times can range from 16 to 24 weeks. For customized AGV solutions, the timeline from design to commissioning can be 6 to 9 months. Proactive planning is crucial. Reputable suppliers manage regional inventory of critical spare parts and may have demonstration or stock models available for quicker deployment. The structural racking, often sourced and fabricated more locally, can usually be delivered on a parallel timeline.

4. How do we handle the storage of slow-moving inventory (Dead Stock) in a high-density system?

Optimizing narrow aisle space utilization involves intelligent slotting. Slow-moving items are typically assigned to the less accessible, higher locations within the dense racking array. Some designs incorporate a hybrid approach: using the highest-density narrow aisle setup for fast and medium-moving goods, and a small section of drive-in or push-back racking for very slow-moving or dead stock pallets. The WMS is configured to enforce this logic automatically.

5. What kind of ongoing maintenance is required, and how is it managed?

A planned preventive maintenance (PPM) program is vital. For VNA trucks, this includes regular checks of hydraulic systems, guidance sensors, forks, and electrical components. For AGVs, it involves battery health monitoring, sensor calibration, and software updates. Maintenance contracts with local service technicians are highly advisable. The system’s design emphasizes accessibility for maintenance, and modern equipment often features remote diagnostic capabilities, allowing experts to troubleshoot issues online, reducing downtime.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com