📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Is Your Narrow Aisle Racking Installation Cost Worth It? A Definitive ROI Maximization Guide

You’re here because you’ve seen the quotes. The numbers for your planned narrow aisle racking installation are on the table, and a critical question is forming in your mind: “Is this investment truly worth it?” This isn’t just a question about price; it’s a question about value. Many logistics managers and business owners focus solely on the upfront narrow aisle racking installation cost, but that’s a myopic view. The real metric that should command your attention is Return on Investment (ROI).

A properly planned and executed narrow aisle system isn’t an expense; it’s a capital improvement that transforms your warehouse operations. This definitive guide moves beyond simple price comparisons. We will dissect the core components of narrow aisle racking installation, reveal the hidden factors that impact your final cost, and provide you with a clear, actionable framework to calculate and maximize your ROI. By the end, you will have the expert knowledge to not only justify the investment but to ensure it delivers superior value for years to come, making your warehouse a model of efficiency and profitability.

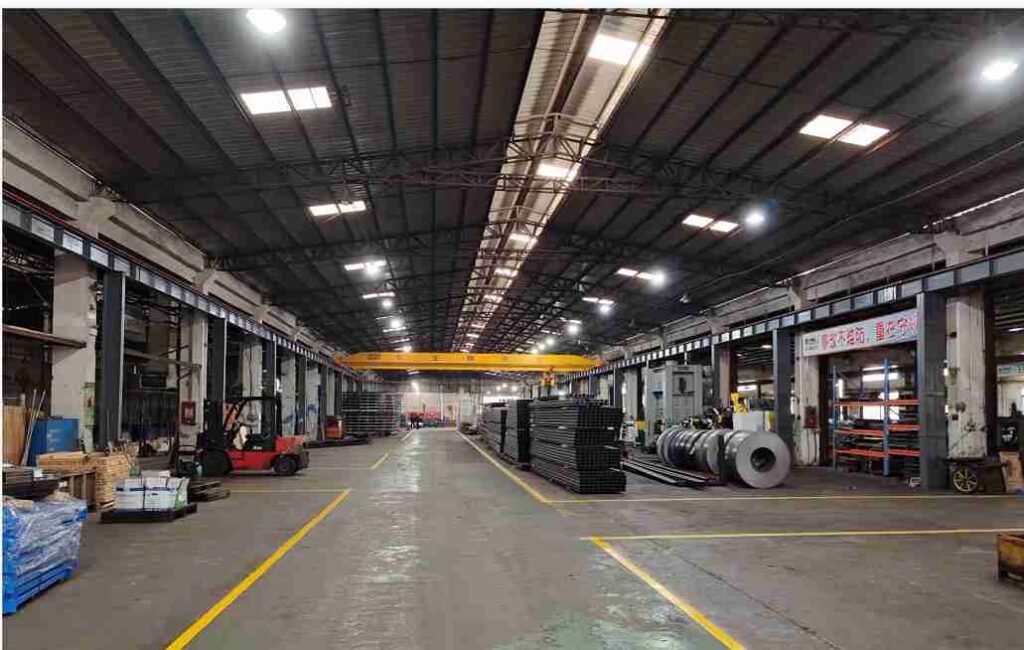

warehouse layout planning for narrow aisle racking installation cost optimization

Decoding the Numbers: What You’re Really Paying For in a Narrow Aisle Racking Installation

When you receive a quotation for a narrow aisle racking system, it’s tempting to look at the bottom line and make a snap judgment. However, that final figure is a synthesis of multiple critical components. Understanding what you’re paying for is the first step in assessing value and preventing costly surprises. A thorough analysis of the narrow aisle racking installation cost reveals much more than just the price of steel; it reveals the quality, safety, and long-term viability of your storage solution. Companies that fail to understand this often find themselves facing unexpected expenses down the line, turning what seemed like a low narrow aisle racking installation cost into a costly mistake.

warehouse layout planning for narrow aisle racking installation cost optimizationThe Core Components of Your Narrow Aisle Racking Installation Cost

A reputable supplier will provide a transparent breakdown. Here’s what to look for:

Structural Steel and Components:This is the raw material cost of the upright frames, beams, bracing, and footplates. The quality of the steel (grade, yield strength) and the manufacturing tolerances significantly influence both the price and the long-term durability and safety of the system. Cheaper, inferior steel can lead to deflection and premature wear, directly impacting the long-term value of your narrow aisle racking installation cost.

Specialized Narrow Aisle Equipment: Unlike traditional pallet racking, narrow aisle systems require specific equipment. This includes guide rails for the forklifts to run on, which reduce the aisle width and require precise installation. The cost of these rails, their anchoring systems, and any required floor preparation are a unique part of the narrow aisle racking installation cost that must be carefully evaluated.

Professional Installation Labor and Engineering: This is not a DIY project. The cost includes certified installers who understand the critical tolerances involved. Even a slight deviation in vertical alignment can render a narrow aisle system unusable. This labor also encompasses project management, on-site supervision, and crucially, the structural engineering sign-off that ensures the system is designed for your specific loads and seismic conditions. This expertise is a non-negotiable part of the narrow aisle racking installation cost that guarantees performance.

Permits and Compliance Fees: Depending on your location, your project may require building permits. A professional installer will manage this process, and the associated fees are often included in the quote. These regulatory requirements are a fixed component of any legitimate narrow aisle racking installation cost assessment.

The Hidden Variables That Can Make or Break Your Budget

The quote you receive is often based on ideal site conditions. The reality can be different, and these variables are where budgets can unravel. A comprehensive understanding of these factors is essential for accurately forecasting the true narrow aisle racking installation cost.

Site Readiness and Floor Flatness (FF/FL): Narrow aisle forklifts operate with clearances of mere inches. The floor flatness tolerance (FF/FL) is exceptionally strict. If your slab requires grinding or topping to achieve the required specification, this can add a significant, unforeseen cost to your project. This is perhaps the most common variable that affects the final narrow aisle racking installation cost, and it underscores the importance of a professional site survey.

Existing Infrastructure Obstacles: Sprinkler lines, electrical conduits, lighting, and HVAC ducts may need to be relocated to accommodate the new, taller racking system. This coordination with other trades is a common source of cost escalation and project delay. A detailed site survey can identify these issues early, preventing them from inflating the narrow aisle racking installation cost later.

Project Timeline and Phasing: A “crash” project that requires overtime labor and expedited material shipping will cost substantially more than a well-planned project with a realistic timeline. If you need to maintain operations during the installation, requiring phased work, this complexity will also be reflected in the labor <b>cost</b>. The timeline you set directly influences the final narrow aisle racking installation cost.

The ROI Equation: Moving Beyond Simple Payback Period

Calculating the ROI of your narrow aisle racking installation requires looking at both the quantifiable financial gains and the significant strategic advantages. Focusing solely on the initial narrow aisle racking installation cost ignores the powerful financial returns that a properly implemented system generates. The true narrow aisle racking installation cost must be weighed against a multi-year horizon of operational savings and efficiency gains.

Quantifiable Gains: The Tangible Benefits You Can Bank On

These are the benefits you can directly measure and assign a dollar value to. These gains directly offset the initial narrow aisle racking installation cost and begin generating a positive return.

Dramatic Increase in Storage Density: This is the primary driver. By reducing aisle width from, for example, 12-13 feet for a VNA truck to 6-7 feet, you can increase your storage capacity by 40-50% within the same building footprint. This defers or eliminates the need for a costly facility expansion or relocation. The value of the real estate you save is a direct financial return that can quickly justify the narrow aisle racking installation cost.

Boost in Operational Throughput and Picking Efficiency: Narrow aisle systems, especially when paired with the right narrow aisle forklifts, drastically reduce travel time for operators. Less time traveling means more time lifting, storing, and retrieving. This leads to a measurable increase in pallets moved per hour and a reduction in labor costs per pallet. This efficiency gain is a recurring annual saving that makes the narrow aisle racking installation cost a wise investment.

Reduced Product Damage and Enhanced Safety: The guide rails in a narrow aisle system physically keep the forklift on course, minimizing the chance of impact with the racking uprights. This leads to less product damage, lower racking repair costs, and a safer working environment, which in turn can reduce insurance premiums. These risk-mitigation benefits provide a strong financial argument for the narrow aisle racking installation cost.

The Strategic Advantages: Intangible Benefits with Real Impact

Some benefits are harder to quantify but are just as critical for long-term competitiveness. While not directly reducing the narrow aisle racking installation cost, they add immense value to the investment.

Improved Inventory Accuracy and Control:A more organized, high-density storage system makes cycle counting and inventory management far more efficient and accurate. This reduces stockouts and overstocking, improving cash flow. This operational clarity is a hidden benefit that amplifies the value received from the narrow aisle racking installation cost.

Future-Proofing Your Operations: Investing in a robust, high-quality narrow aisle racking system creates a scalable platform for future growth. It can easily integrate with warehouse management systems (WMS) and can be adapted to accommodate technologies like <a href=”/agv-solutions”>AGVs or other automation down the line. This forward compatibility ensures that the narrow aisle racking installation cost contributes to long-term business agility.

Enhanced Brand Reputation and Reliability:The ability to fulfill orders faster and more accurately with fewer errors builds customer trust and loyalty, giving you a powerful competitive edge. This market perception of reliability is an invaluable asset that stems from the operational excellence enabled by your investment, making the narrow aisle racking installation cost a strategic differentiator.

A Step-by-Step Framework to Calculate Your Projected ROI

Let’s put theory into practice. Here is a simplified framework to calculate the potential ROI for your project. This model will clearly show how the initial narrow aisle racking installation cost is transformed into a powerful financial asset.

Step 1: Calculate Your Current Cost of Operations

Establish your baseline. You need to know where you are to measure improvement. This baseline is crucial for contextualizing the narrow aisle racking installation cost.

Labor Cost: (Number of operators) x (Hourly wage + benefits) x (Hours worked).Real Estate Cost: Cost per square foot/month x Total warehouse square footage.Current Throughput: Average pallets moved per hour/per operator.Incidentals: Annual cost of product damage + racking damage repairs.

Step 2: Project Your Post-Installation Gains

Estimate the improvements based on industry averages and your specific setup. These gains are the mechanism for recovering the narrow aisle racking installation cost.

Storage Gain: (Current pallet positions) x (Estimated 40% increase) = New capacity. Value this gain based on the cost of alternative storage (e.g., leasing more space). This directly offsets the <b>narrow aisle racking installation cost.

Efficiency Gain: (Current pallets/hour) x (Estimated 20-30% increase) = New throughput. Calculate the labor savings from moving the same number of pallets in fewer hours. This recurring saving quickly amortizes the narrow aisle racking installation cost.

Damage Reduction: Estimate a 60-70% reduction in your current annual damage costs. This saving protects your bottom line and improves the ROI of the narrow aisle racking installation cost.

Step 3: Run the ROI Calculation

Now, plug the numbers into the standard ROI formula.

Annual Return = (Value of Storage Gain + Labor Savings + Damage Reduction Savings)

Total Investment = (Total Narrow Aisle Racking Installation Cost + Cost of New Narrow Aisle Forklifts)

ROI = (Annual Return – Total Investment) / Total Investment x 100

Real-World ROI Calculation Example

Let’s assume:

Total Investment: $300,000 (for both racking and one new forklift)

Annual Return:

Deferred warehouse expansion: $80,000/year value.

Labor efficiency savings: $50,000/year.

Damage reduction: $10,000/year.

Total Annual Return: $140,000

ROI Calculation: ($140,000 – $300,000) / $300,000 * 100 = -53% in Year 1.

This seems negative, but it’s misleading. The system has a payback period of just over 2 years ($300,000 / $140,000 ≈ 2.14 years). From year 3 onward, the system generates a pure annual profit of $140,000 against the sunk cost. Over a 10-year lifespan, the total return is $1.4 million on a $300,000 investment—a phenomenal return. This analysis demonstrates that the narrow aisle racking installation cost is not a mere expense but a capital deployment that generates substantial returns.

The strategic management of the narrow aisle racking installation cost is what separates industry leaders from the rest. A detailed evaluation of the narrow aisle racking installation cost is therefore paramount for any business looking to optimize its logistics footprint. The narrow aisle racking installation cost should be viewed through the lens of value generation, not just accounting. When companies analyze the narrow aisle racking installation cost with this mindset, they often discover that the investment is one of the most profitable they can make.

Choosing the Right Partner: Why Expertise Trumps a Cheap Price Every Time

The lowest bidder is often the riskiest choice. The precision required for a successful narrow aisle racking installation is immense. An error in the foundation of the system can lead to operational nightmares, constant repairs, and even safety hazards. The initial narrow aisle racking installation cost quoted by an inexperienced supplier may be low, but the total cost of ownership, including downtime and repairs, will be exorbitant. Therefore, selecting a partner based on expertise and a proven track record is the most effective way to ensure the narrow aisle racking installation cost delivers maximum value. The true narrow aisle racking installation cost encompasses not just the price, but the performance and reliability of the installed system.

The Critical Role of a Site Survey and Professional Assessment

Never accept a quote based on rough drawings. Insist on a comprehensive site survey conducted by an experienced engineer. This survey should measure floor flatness, identify all overhead obstacles, and verify soil reports for new constructions. This due diligence is your primary defense against hidden costs and is non-negotiable for maximizing your ROI. A partner like [Your Company Name] will always insist on this step—it protects both of us. This rigorous assessment is fundamental to providing an accurate and reliable narrow aisle racking installation cost projection. A professional evaluation of the narrow aisle racking installation cost must include this critical step to be considered credible. The narrow aisle racking installation cost provided after a thorough survey is a figure you can trust.

Questions to Ask Your Potential Narrow Aisle Racking Supplier Can you provide a detailed, line-item breakdown of the quotation? A transparent breakdown is essential for understanding the narrow aisle racking installation cost.Do you conduct a formal, in-person site survey before finalizing the quote? This is non-negotiable for an accurate narrow aisle racking installation cost.Are your installers certified, and what is your safety record (e.g., EMR rate)? The quality of installation directly affects the long-term value of your narrow aisle racking installation cost.Can you provide case studies or references from projects of a similar scale? Past performance is the best indicator of how they manage the narrow aisle racking installation cost and deliver value.

Who is responsible for obtaining the necessary permits? Clarifying this avoids unexpected additions to the narrow aisle racking installation cost.What is your process for handling unforeseen site conditions? A professional process protects you from uncontrolled escalations in the narrow aisle racking installation cost.Do you provide the structural engineering calculations and stamps? This ensures the system’s safety and is a critical component of the professional narrow aisle racking installation cost.

Conclusion: Investing in Intelligence, Not Just Steel

The question is no longer, “What is the narrow aisle racking installation cost?” The definitive question is, “What is the value of transforming my warehouse into a high-density, high-throughput, and highly profitable operation?” The initial investment is a single data point in a much larger financial picture. By focusing on the total cost of ownership and the projected ROI, you shift the conversation from price to performance.

A well-executed narrow aisle racking installation is one of the smartest investments a logistics-dependent business can make. It is an investment in intelligence, efficiency, and future growth. Don’t just buy racking; invest in a solution that pays for itself and then continues to pay you back for the life of your facility. The strategic management of the narrow aisle racking installation cost is a hallmark of a forward-thinking organization.

When you partner with experts who understand how to optimize the narrow aisle racking installation cost for long-term value, you are not just installing a storage system; you are building a competitive advantage. The narrow aisle racking installation cost, therefore, should be seen as an investment in your company’s operational excellence and future profitability. A detailed, professional assessment of the narrow aisle racking installation cost is the first step toward unlocking this value.

Frequently Asked Questions (FAQs)

What is the typical lifespan of a professionally installed narrow aisle racking system?

With proper use and minimal impact, a high-quality narrow aisle system from a reputable supplier like us can have a functional lifespan of 20+ years. The longevity is directly tied to the quality of the initial installation and the ongoing maintenance. This long lifespan dramatically improves the ROI, effectively amortizing the initial narrow aisle racking installation cost over a much longer period, which enhances its value proposition.

How does the cost of a narrow aisle system compare to a mobile pallet racking system?

Mobile racking typically has a higher upfront cost due to the complex carriage mechanism. While it offers even greater density, its throughput can be slower. Narrow aisle offers an excellent balance of high density, high throughput, and a lower initial investment than full mobile systems. This makes the narrow aisle racking installation cost a very compelling value proposition for businesses seeking to optimize both space and operational speed. The narrow aisle racking installation costoften represents the optimal balance of performance and investment.

Can my existing forklifts be used in a narrow aisle system?

Almost certainly not. Standard counterbalance forklifts require wider aisles. Narrow aisle systems require specialized equipment like narrow aisle forklifts (turret trucks, order pickers) that operate within the guide rails. The cost of this new equipment must be factored into your total project budget and will influence the overall narrow aisle racking installation cost. It is a crucial part of the total project investment.

What kind of ongoing maintenance should I budget for after installation?

You should budget for regular inspections of the racking structure (especially beam connectors and uprights) and the guide rails. Furthermore, the specialized narrow aisle forklifts require a strict preventative maintenance schedule to ensure uptime and safety. While this is a separate operational cost, it is essential for protecting the value of your initial narrow aisle racking installation cost investment and ensuring its long-term performance and safety.

We have a busy warehouse. Can the installation be done in phases to minimize disruption?

Absolutely. A seasoned installer will develop a detailed phasing plan that allows you to maintain operations. This may involve working in specific zones, often during off-peak hours or weekends, to systematically transition your inventory from old storage to the new narrow aisle racking system with minimal impact. While phased installation may slightly affect the project timeline and potentially the narrow aisle racking installation cost due to increased project management complexity, it is a standard and highly effective approach for active facilities. The ability to phase the work is a key service that ensures the narrow aisle racking installation cost</b> does not include the hidden expense of major operational shutdowns.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com