📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Engineered for Efficiency: The Definitive Guide to Maximizing Warehouse Potential with Selective Pallet Racking

In the dynamic landscape of global logistics, where speed, accuracy, and cost-control are paramount, the structural backbone of any successful operation is often the most understated. For distribution centers in Indonesia, manufacturing plants in Mexico, cold storage facilities in the UAE, and e-commerce hubs in South Africa, the choice of storage infrastructure directly dictates competitive advantage. Among the array of solutions, one system consistently proves to be the versatile, resilient, and intelligent cornerstone: selective pallet racking.

This comprehensive exploration delves beyond the basic specifications, offering a masterclass in how truly optimized selective pallet racking transforms physical space into a strategic asset. It is a detailed examination of engineering principles, strategic configurations, and technological integrations that define world-class warehouse operations, providing facility managers and business owners with the knowledge to make profoundly impactful investment decisions.

The Unmatched Architectural Superiority of Modern Selective Pallet Racking

The fundamental premise of selective pallet racking is deceptively simple: provide direct, unimpeded access to every single pallet load. However, the engineering and design execution of this premise separate adequate storage from a high-performance storage system. A superior selective pallet racking installation is a symphony of precision-designed components, each playing a critical role in safety, durability, and adaptability.

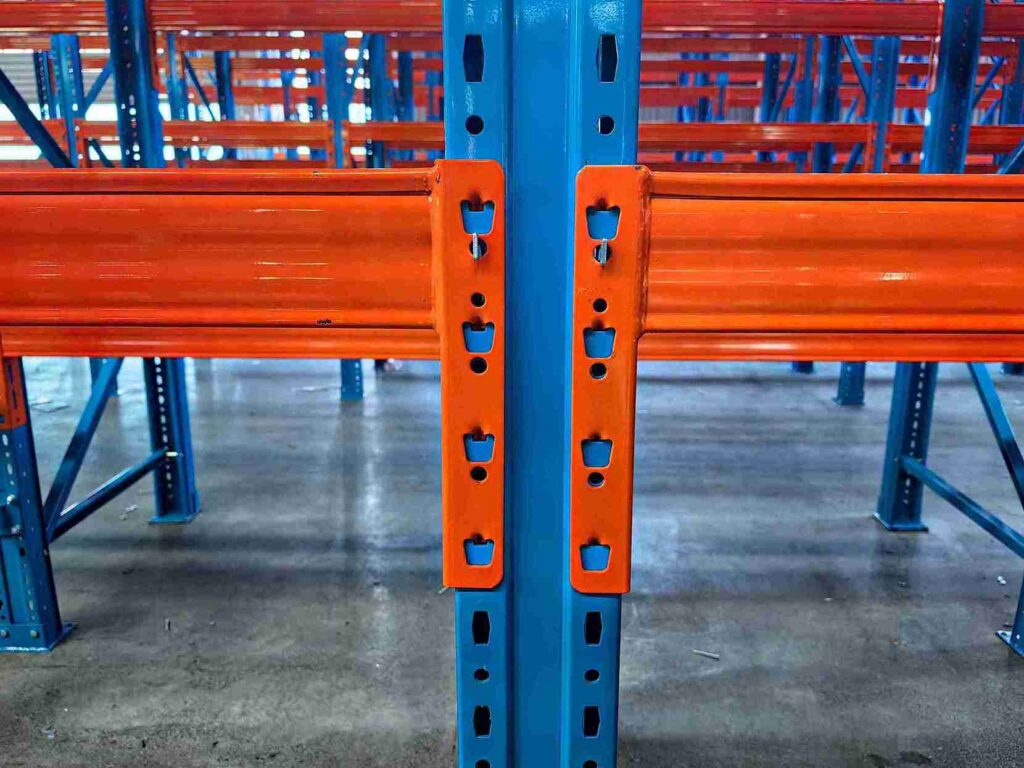

The Vertical Backbone: Upright Frames Engineered for Stability. The upright frame, or column, is the primary load-bearing element. Industrial-grade selective pallet racking utilizes high-tensile steel columns formed through a cold-roll process, creating a consistent, robust profile. The design of the column’s perforations—most commonly the universal teardrop pattern—is crucial. This patented design allows for secure, tool-less beam connection and enables virtually infinite adjustability in 2-inch or 3-inch increments.

For installations in seismically active regions like Chile or the Philippines, or for structures exceeding 12 meters in height, structural selective pallet racking is employed. This variant uses hot-rolled, C-channel steel with bolted connections, offering significantly greater load-bearing capacity and moment resistance to handle dynamic forces.

The Horizontal Workhorses: Load Beams and Their Critical Role. Load beams transform vertical frames into storage positions. The standard step-beam design incorporates a integral locking device that snaps securely into the upright’s teardrop. Capacity ratings are non-negotiable. A beam listed at 5,000 lbs per pair is engineered to hold that uniformly distributed load with a built-in safety factor, often 1.67:1, accounting for incidental impact and slight load imperfections. Beam deflection—the natural bend under load—is strictly regulated by the Rack Manufacturers Institute (RMI) standards to ensure pallet stability and system integrity.

For double-deep selective pallet racking configurations, specially designed beams with extended reach allow secure storage of two pallets deep, effectively doubling density while maintaining reasonable selectivity.

The Supporting Layer: Decking, Safety, and Specialized Accessories. While pallets can rest directly on beams, decking is a hallmark of a professional selective pallet racking system. Heavy-gauge welded wire grid decking serves multiple functions: it prevents pallets from shifting or falling through, provides a secondary level of safety for workers, allows for fire sprinkler penetration, and facilitates air circulation. Beyond decking, a suite of accessories completes the system.

Column protectors (upright guards) are not optional; they are sacrificial components designed to absorb forklift impact, protecting the critical structural upright. Other essential additions include row spacers for maintaining precise aisle widths, cross-bracing stabilizers, and pallet support bars for unstable loads. Each accessory enhances the safety, organization, and longevity of the selective pallet racking installation.

Strategic Operational Advantages: Why Selective Pallet Racking Powers Growth

The widespread global adoption of selective pallet racking is a direct result of its alignment with core business objectives: reducing cost, mitigating risk, and enabling scalable growth. Its advantages are both immediate and long-term, offering a compelling return on investment.

Unparalleled Flexibility in a Dynamic Market. The modular nature of selective pallet racking is its greatest strategic asset. Inventory profiles are never static; SKU counts expand, product dimensions change, and seasonal fluctuations demand adaptability. With a selective pallet racking system, reconfiguring storage layouts is a straightforward process. Beam levels can be relocated in minutes without dismantling the structure.

This means a warehouse can efficiently store appliances one quarter and consumer electronics the next. For businesses in emerging markets experiencing rapid growth, this scalability is invaluable. New racking bays can be added seamlessly, allowing storage capacity to expand in concert with sales, without requiring a costly and disruptive facility relocation.

Optimizing the Cube: The Science of Space Utilization. Warehouse profitability is often measured in cubic meter efficiency. Selective pallet racking allows for the precise calibration of storage density against accessibility. The key variable is aisle width. Using a standard counterbalance forklift might require a 3.5-meter aisle. By transitioning to a narrow-aisle (NA) reach truck, that aisle can be reduced to approximately 2.7 meters.

Implementing a forklift-agv or a very-narrow-aisle (VNA) turret truck can shrink aisles to under 2 meters. Each reduction converts previously non-productive aisle space into revenue-generating storage positions. This calculated optimization, enabled by the adaptable framework of selective pallet racking, maximizes the return on expensive industrial real estate in cities like Dubai, Bangkok, or São Paulo.

Driving Efficiency Through 100% Direct Access. In fast-moving logistics environments, speed is currency. Unlike dense storage methods (drive-in, push-back), which operate on a Last-In, First-Out (LIFO) basis, selective pallet racking provides First-In, First-Out (FIFO) accessibility and direct access to every SKU. This eliminates the time-consuming and labor-intensive task of “digging” for pallets. It streamlines both put-away and picking cycles, reduces forklift travel time, and accelerates order fulfillment.

For third-party logistics (3PL) providers or e-commerce operations where order profiles are unpredictable and turnaround times are critical, the efficiency gain offered by a well-organized selective pallet racking system is a fundamental competitive differentiator.

The True Economics: Analyzing Total Cost of Ownership (TCO). While the initial purchase price is a consideration, the true cost of a storage system is measured over its 15-20 year lifespan. Selective pallet racking excels in TCO analysis. Its simple design requires minimal maintenance—no complex mechanical parts to repair or replace. Its compatibility with a wide range of standard material handling equipment prevents costly fleet specialization.

Its durability, when properly specified and installed, ensures decades of reliable service. Furthermore, its reconfigurability and expandability protect the initial capital investment from obsolescence. When these factors are modeled, selective pallet racking consistently presents the most financially sound, low-risk storage solution for capital-conscious businesses.

The Imperative of Professional Design: Engineering Your Storage System

Treating the procurement of selective pallet racking as a commodity purchase is a profound and potentially dangerous mistake. A properly engineered selective pallet racking system is the product of meticulous analysis and professional design, translating operational requirements into a safe, optimized physical structure.

The Foundation of All Design: Comprehensive Load Analysis. The design process begins with a rigorous assessment of the stored product. This includes:

Unit Load Dimensions & Weight: Capturing the maximum pallet size and the heaviest possible load, not averages.

Inventory Profile & Turnover: Understanding SKU velocity to inform slotting strategy within the selective pallet racking grid.

Material Handling Equipment (MHE) Specifications: The type, mast height, and load capacity of forklifts or forklift-agv units determine required clearances, aisle widths, and potential impact forces.

Site-Specific Environmental Factors: This includes seismic zone data (critical for installations in Central Asia or along the Pacific Rim), wind loads for semi-enclosed facilities, and corrosion resistance requirements for coastal environments in West Africa or Southeast Asia. High-quality epoxy or powder coatings are essential in these contexts.

Structural Calculations and Compliance: The Engineer’s Seal. Using the load data, qualified structural engineers perform calculations to specify the exact upright frame gauge, depth, and connection type, as well as the beam profile and capacity. These calculations adhere to stringent international standards such as RMI ANSI MH16.1, the European FEM 10.2.02, or local building codes.

The output is a set of stamped design drawings and a comprehensive load table. This documentation is not merely bureaucratic; it is the legal and safety blueprint for the selective pallet racking installation and is often required for insurance and regulatory compliance.

The Critical Role of Professional Installation and Anchorage. Engineering excellence can be nullified by poor installation. A professional installation team follows a strict protocol: laser-leveling of base plates to ensure perfect plumb, the use of certified anchor bolts torqued to precise specifications, and the systematic assembly and alignment of all components. The choice of anchorage—whether concrete wedge anchors, chemical anchors, or seismic shear plates—is determined by the floor composition and design loads.

The final step is the affixation of load application and restraint (LOAD) plaques to each rack bay, providing clear, permanent documentation of its engineered capacities. This rigorous process ensures the selective pallet racking system performs as intended, guaranteeing safety and longevity.

The Smart Warehouse Synergy: Integrating Selective Pallet Racking with Automation

The true potential of a selective pallet racking system is fully realized when it becomes the physical substrate for a digitally integrated smart warehouse. It provides the organized, predictable, and scalable framework upon which automation software and hardware depend.

The Physical-Digital Bridge: Selective Pallet Racking and WMS. A Warehouse Management System (WMS) is the brain of a modern facility. The selective pallet racking system provides the physical coordinate system—aisle, bay, level, position—that the WMS uses to map inventory. Advanced WMS logic determines the optimal put-away location based on product dimensions, weight, turnover rate, and compatibility. It then directs the forklift operator, via radio frequency (RF) terminal, or a forklift-agv, via integrated software, to the exact location. This synergy transforms the selective pallet racking structure from passive storage into an active, dynamically managed inventory engine, minimizing travel time and maximizing space utilization.

Automating the Aisle: AGVs, AS/RS, and Selective Racking. Selective pallet racking is the preferred infrastructure for a wide range of automation:

Automated Guided Vehicles/Carts (AGVs/AGCs): These robots transport pallets to and from the selective pallet racking faces. They require precisely aligned aisles and often interact with fixed transfer points at the rack base.

Autonomous Mobile Robots (AMRs) & Forklift-AGVs: More advanced systems, like forklift-agv units, can autonomously perform the complete pallet storage and retrieval cycle, lifting loads to heights of 10+ meters. Integrating these systems demands reinforced racking design, precise positioning guides, and often proprietary communication interfaces.

Automated Storage and Retrieval Systems (AS/RS): While often associated with taller, single-aisle systems, shuttle-based AS/RS can operate within a selective pallet racking framework, using autonomous bots on rails to store and retrieve loads deep within the rack, creating a high-density hybrid solution.

Data, Visibility, and Continuous Improvement. The integration of selective pallet racking with warehouse control systems (WCS) and IoT sensors creates a data-rich environment. Telemetry from forklift-agv fleets can inform rack wear patterns. Pick-rate data from the WMS can highlight high-activity zones within the selective pallet racking layout, prompting strategic repositioning of fast-moving SKUs to the “golden zone” (waist-high levels) to further boost productivity. This closed-loop of data and physical infrastructure is the hallmark of a world-class operation.

Advanced Configurations and Industry-Specific Applications

The standard single-deep, two-wide configuration of selective pallet racking serves most needs, but engineered variations address specific challenges and industry requirements.

Hybrid Density Solutions: Double-Deep and Pallet Flow Integration. For operations needing higher density without sacrificing full selectivity, double-deep selective pallet racking stores two pallets deep per side. This requires forklifts with double-reach attachments or specialized forklift-agv. It is ideal for storing larger quantities of medium-turnover SKUs. In high-volume picking environments, integrating carton flow racking into the lower levels of a selective pallet racking structure creates a highly efficient pick module. Full pallets are stored above, and cases are gravity-fed to pickers at ergonomic stations below.

Vertical Expansion: Multi-Tier Racking and Mezzanine Systems. In facilities with high clear heights, selective pallet racking can be designed to support multiple storage levels via structural mezzanines. The racking uprights themselves become the primary support columns for elevated floors, creating two or three levels of storage or office space within the same footprint. This is an extremely cost-effective alternative to building expansion, particularly in urban industrial zones where land is at a premium.

Specialized Applications: Cold Storage, Bulk Handling, and Manufacturing.

Cold Storage: In freezer and cooler applications, selective pallet racking is fabricated from special low-temperature steels and uses lubricants that remain functional at sub-zero temperatures. The open design promotes critical air circulation around loads.

Bulk Industrial & Drum Storage: With the addition of specialized beam-mounted supports or wire containers, selective pallet racking securely stores heavy drums, rolls, or oversized industrial parts.

Manufacturing & Work-in-Process (WIP): Selective pallet racking is often used within manufacturing plants to organize raw materials and WIP, feeding production lines in a controlled, FIFO manner. Its flexibility is key as production needs change.

The Global Procurement Strategy: Selecting a Partner for the Long Term

For businesses operating in Southeast Asia, Africa, the Middle East, and Latin America, choosing the right supplier for a selective pallet racking system is a strategic decision with decades-long implications. It extends far beyond initial price comparison.

Evaluating Quality and Safety Credentials. The baseline requirement is certification to international manufacturing and safety standards. Suppliers should provide evidence of ISO 9001 certification for quality management and design their products to RMI, FEM, or equivalent standards. Component test certificates from independent laboratories are a strong indicator of integrity. For seismic zones, evidence of successful shake-table testing or engineering calculations from a recognized authority is non-negotiable.

The Value of In-Region Expertise and Project Management. A supplier with a physical presence and a track record in the target region brings invaluable advantages. They understand local building codes, import regulations, and climatic challenges. They offer end-to-end project management: conducting the initial site survey, providing detailed CAD layouts and engineering drawings, managing sea or land freight logistics, handling customs clearance, and executing the installation with trained, local crews. This single-point accountability reduces risk and ensures a smooth, on-schedule deployment of the selective pallet racking system.

Lifecycle Support: Maintenance, Inspection, and Expansion. The relationship should be viewed as a partnership. Premier suppliers offer ongoing support packages, including scheduled preventive maintenance inspections. These inspections, conducted by certified technicians, check for plumb, anchor integrity, beam connector engagement, and impact damage, providing a formal report and corrective recommendations. The availability of a local spare parts inventory for beams, connectors, and safety devices is crucial for minimizing downtime. Furthermore, a reliable partner should be able to seamlessly design and execute expansions or reconfigurations of the original selective pallet racking system years later, ensuring perfect compatibility.

Conclusion: Building a Resilient and Adaptive Logistics Foundation

In the relentless pursuit of supply chain excellence, infrastructure decisions carry enduring weight. Selective pallet racking represents a paradigm of functional design—simple in concept but infinitely adaptable in expert application. Its enduring relevance in warehouses across the globe is a testament to its core virtues: unmatched accessibility, inherent flexibility, and robust, cost-effective performance.

Investing in a professionally engineered and integrated selective pallet racking system is not merely a purchase of steel; it is a capital allocation towards building a resilient, efficient, and scalable operational foundation. This foundation supports lean inventory practices, enables the adoption of advanced automation, empowers a productive workforce, and ultimately delivers a superior return on investment by turning cubic space into a controlled, high-velocity asset.

For logistics leaders navigating the complexities of growth in dynamic global markets, mastering the implementation of advanced selective pallet racking solutions is not just an operational task—it is a critical strategic imperative for future success.

Frequently Asked Questions (FAQs)

1. What is the realistic lifespan of a properly maintained selective pallet racking system, and what factors most influence its longevity?

The service life of a high-quality selective pallet racking system, when specified correctly for its application and maintained, routinely exceeds 20 years. The primary factors influencing longevity are: Load Discipline: Never exceeding the stated capacity on load plaques. Forklift Impact Management: The use of column protectors, guard rails, and operator training significantly reduces structural damage. Environmental Conditions: Racking in corrosive environments (e.g., coastal, chemical) requires appropriate steel grades and protective coatings. Professional Inspections: An annual formal inspection by a qualified technician to identify and rectify minor issues before they escalate is the single most effective practice for extending system life.

2. How does the design process for selective pallet racking account for the use of both traditional forklifts and emerging Forklift-AGV systems?

The design process integrates key equipment parameters. For traditional forklifts, the turning radius and mast height determine minimum aisle width and vertical clearances. For a forklift-agv, the design requirements are more precise. Engineers must account for the forklift-agv‘s exact positioning accuracy, its guidance system (e.g., laser targets on the rack), and potential repeated micro-impacts. This often leads to specifications for heavier-duty column protectors, reinforced footplates, and ultra-precise aisle alignment tolerances. A forward-thinking design will often accommodate both initially, with a clear pathway to fully automated aisles in the future.

3. Can selective pallet racking be effectively used in warehouses with very uneven floors?

While a perfectly level floor is ideal, professional installers have methods to compensate for slab deviation. The critical metric is plumb—the upright frames must be perfectly vertical. Using laser levels, installers shim the base plates with high-grade, load-rated steel shims to achieve plumb on an uneven floor. However, there are limits. Severe floor heave or settlement (beyond typical tolerances) may require floor grinding or corrective sub-floor work before a safe and stable selective pallet racking installation can proceed. A professional site survey will identify this requirement early.

4. What are the key differences in the design and specification of selective pallet racking for cold storage environments versus ambient warehouses?

Cold storage applications impose unique demands on selective pallet racking. Material Science: The steel must be certified for low-temperature service (often using specific grades with Charpy V-Notch impact test ratings) to prevent brittle fracture. Coatings & Hardware: Powder coatings and lubricants must remain flexible and adherent at temperatures as low as -30°C. Thermal Bridging: Designers may specify thermal break pads between base plates and the floor to reduce heat transfer and prevent floor ice heave. Airflow: Layouts are carefully planned to align with cooler airflow patterns to maintain consistent temperatures, making the open design of selective pallet racking particularly advantageous.

5. How does a business justify the investment in a high-specification, professionally engineered selective pallet racking system versus a lower-cost, catalog-grade alternative?

Justification is built on risk mitigation and total cost of ownership (TCO).

Risk: An engineered system comes with certified load ratings, seismic calculations (if needed), and professional installation—dramatically reducing the risk of catastrophic collapse, which carries immense safety, financial, and reputational costs.

Operational Efficiency: A precision-designed system maximizes storage density and throughput, generating ongoing savings in space and labor costs.

Longevity & Flexibility: Higher-grade materials and finishes last longer and withstand reconfiguration.

Insurance & Compliance: Many insurance providers require engineered drawings and may offer lower premiums for certified installations. When modeled over a 15-year horizon, the higher initial investment in premium selective pallet racking typically yields a lower TCO and a significantly lower risk profile.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com