📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Beyond Storage: The Integrated Racking System Blueprint for E-commerce Dominance

In the high-stakes arena of global e-commerce, the warehouse has decisively shifted from a passive cost center to the primary engine of competitive advantage. The relentless pressure to fulfill orders with blistering speed and pinpoint accuracy, while managing an explosion of SKUs and surviving brutal peak seasons, ruthlessly exposes the fatal flaws in traditional, disconnected storage setups.

Standard shelving and static pallet racking, once adequate, now create critical bottlenecks that throttle entire operations, leading to delayed shipments, spiraling labor costs, and eroded profit margins. The modern solution is unequivocally not about simply adding more storage space; it is about deploying intelligent, integrated racking systems for e-commerce that are engineered from the ground up for velocity and synchronization.

This definitive guide outlines the strategic blueprint for transforming static storage infrastructure into a dynamic, high-velocity fulfillment asset. It delves into how a unified racking system for e-commerce acts as the foundational physical layer, seamlessly connecting every operational stage from receiving to dispatch, thereby unlocking unprecedented levels of efficiency, accuracy, and scalable growth for businesses targeting markets in Southeast Asia, the Middle East, Latin America, and beyond.

<h2>The High Cost of Disconnected Storage in Modern E-commerce</h2>

A startling number of e-commerce operations, even thriving ones, are hampered by a fragmented warehouse reality: a patchwork of pallet racking in one corner, miscellaneous shelving in another, and conveyors clumsily grafted onto the layout as an afterthought. This disjointed approach creates insidious and continuous drains on productivity and profitability, making the entire operation vulnerable to market shifts. The limitations of a non-integrated racking system for e-commerce become painfully clear under pressure.

<h3>Where Inefficiency Hides: The Silent Profit Killers</h3>

Excessive Travel Time: In a disconnected warehouse, pickers can waste up to 60% of their shift simply walking between disparate storage zones. A properly designed racking system for e-commerce is organized around product velocity and optimized pick paths, dramatically minimizing non-value-added movement.

Dwell Time at Critical Stages: Goods languish in receiving because the put-away process is manual and the storage locations are not pre-allocated by an intelligent system. They stall again in packing and sortation because the workflow from picking to dispatch is not a fluid, continuous stream.

Error-Ridden Operations: Without a system-directed process, reliance on human memory and paper lists leads to a high rate of mis-picks and mis-ships. These errors trigger a cascade of costly consequences, including reverse logistics, reshipments, and most damagingly, customer dissatisfaction.

Inflexibility to Demand Shifts: The dynamic nature of online sales, with seasonal spikes or a suddenly viral product, can bring a traditional warehouse to its knees. A static racking system for e-commerce lacks the modularity and fluidity to adapt, causing severe operational disruption.

<h3>The Integration Mindset: From Static Cost to Dynamic Asset</h3>

The fundamental shift required is to cease viewing warehouse racking as a standalone capital expense and start recognizing it as the critical foundational layer of the entire operational workflow. An integrated racking system for e-commerce is conceptually designed and physically implemented to work in perfect concert with material handling equipment, the human workforce, and the Warehouse Management System (WMS). It is the physical architecture that translates digital commands into tangible, efficient physical motion, making the entire warehouse “intelligent.”

<h2>The Core Components of an Integrated Racking Ecosystem</h2>

A truly transformative integrated racking system for e-commerce functions as a cohesive ecosystem, far greater than the sum of its individual parts. It represents a carefully orchestrated symphony of storage media, automated handling equipment, and intelligent control software.

<h3>1. The Dynamic Storage Layer: Engineered for Velocity and Diversity</h3>

This layer forms the static-yet-intelligent core of the operation. Instead of forcing diverse products into a one-size-fits-all solution, a sophisticated racking system for e-commerce strategically deploys a hybrid mix of storage solutions, each optimized for different product profiles and velocity.

Pallet Flow Racks: Essential for high-volume, full-case picking of fast-moving goods. Utilizing a gravity-fed design, these advanced racking systems for e-commerce enforce perfect FIFO (First-In, First-Out) inventory management. This is non-negotiable for perishable goods, items with expiration dates, or products with high stock rotation.

Carton Flow Racks: The undeniable workhorse for the e-commerce piece-picking environment. Positioned in the fast-moving “golden zone” at ergonomic heights, these racking systems for e-commerce allow pickers to rapidly access the most popular SKUs with minimal reach and zero walking. The continuous flow of cartons ensures the next item is always at the picker’s fingertips.

Selective Pallet Racking: The backbone for reserve storage of medium-to-slow-moving SKUs. When intelligently integrated into the overall layout, these robust racking systems for e-commerce serve as the high-density reservoir that efficiently and systematically replenishes the dynamic forward-pick areas, such as the carton flow lanes.

Multi-Tier Mezzanine Systems: A game-changing solution when warehouse floor space is constrained and expensive. Mezzanines represent the ultimate form of vertical integration, effectively doubling or tripling the usable square footage within the same building envelope. They create dedicated, elevated zones for value-added services like kitting, custom packaging, or high-volume returns processing, all supported by their own level of integrated racking systems for e-commerce.

<h3>2. The Mobility & Automation Layer: The Connective Tissue</h3>

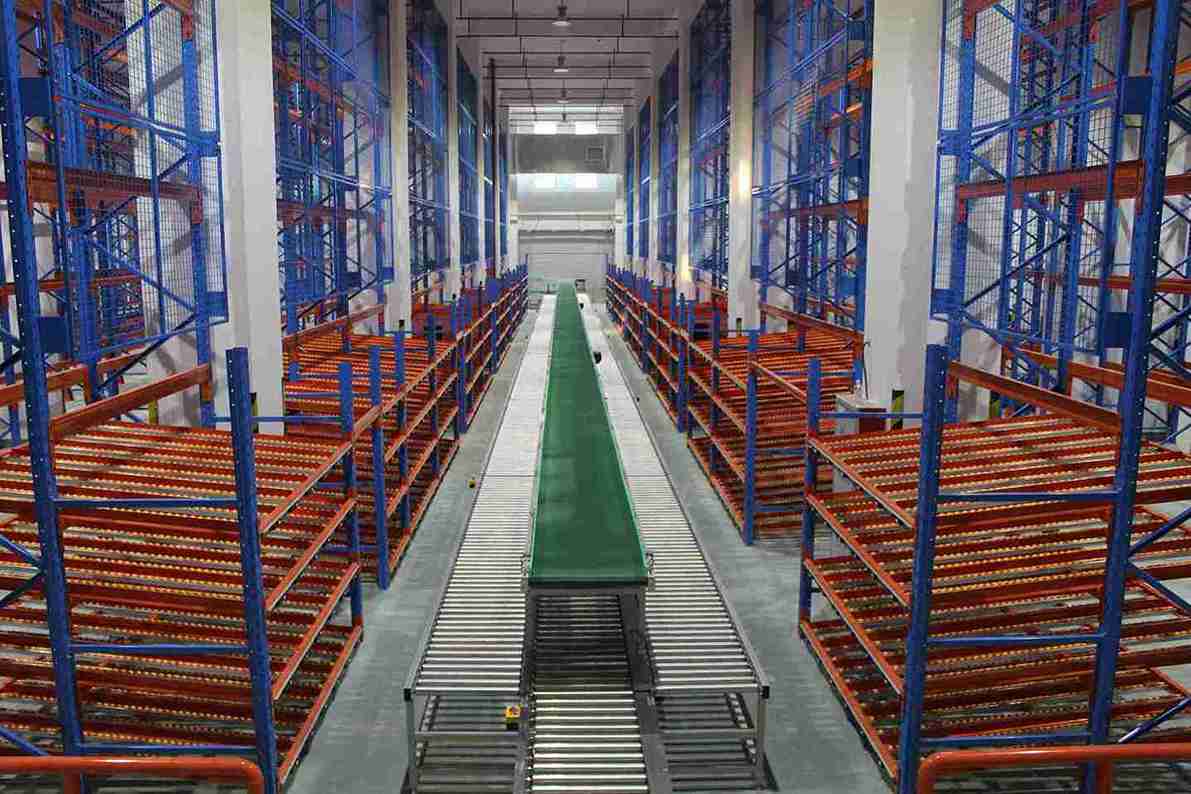

This layer injects kinetic energy into the static storage structure, creating the seamless flow that defines modern efficiency. It is what transforms a collection of racking systems for e-commerce into a living, breathing fulfillment organism.

AGVs (Automated Guided Vehicles): Deployed for consistent, high-volume horizontal transport of palletized loads. These silent workhorses seamlessly shuttle full pallets from receiving docks to their assigned locations in the reserve storage racking system for e-commerce. They also automate the movement of completed orders from packing stations to the dispatch staging area, operating reliably 24/7.

Automated Guided Carts (AGCs): As lighter-duty cousins to AGVs, these units are perfect for moving carts of picked orders through the warehouse. They follow optimized, pre-determined paths, significantly reducing human traffic and congestion around the high-activity racking systems for e-commerce pick zones.

Conveyor & Sortation Systems: These systems act as the high-speed arteries of the integrated operation. A well-engineered conveyor network physically links the picking zones, packing stations, and sortation units, creating a continuous, non-stop flow of goods. Modern cross-belt and tilt-tray sorters interact directly with the output of the racking system for e-commerce, routing individual items or totes to specific dispatch lanes based on carrier, postal code, or order priority.

<h3>3. The Digital Nervous System: WMS & Control Software</h3>

The hardware provides the muscle, but the software provides the brains. A robust, industry-specific WMS is the central intelligence that animates the entire integrated racking system for e-commerce. It exercises command and control by:

Dynamically optimizing put-away locations based on a complex algorithm of product dimensions, weight, turnover velocity, and seasonal demand.

Creating the most efficient pick paths for wave, batch, or single-order picks, directly guiding workers through the racking system for e-commerce layout.

Issuing real-time commands to the AGVs and conveyor systems, dictating their movements and tasks.

Providing unparalleled, real-time inventory visibility and generating deep performance analytics for continuous operational improvement.

<h2>Mapping the Integrated Workflow: From Receiving to Dispatch</h2>

To fully appreciate the transformative power of this approach, one must trace the journey of a single product through a fully synchronized warehouse, witnessing the synergy between components in real-time.

<h3>Stage 1: Intelligent Receiving & Put-Away</h3>

A truck arrives at the receiving dock. Staff scan the pallets or cartons, and the data is instantly transmitted to the WMS. The system immediately identifies the product and, based on its pre-programmed logic, assigns an optimal location within the integrated racking system for e-commerce. This decision could mean:

A specific lane in the pallet flow racking for a fast-moving bulk item needing immediate accessibility.

A high-bay location in the selective pallet racking for medium-term reserve storage.

Simultaneously, an AGV is automatically dispatched to the dock. The pallet is loaded onto it, and the vehicle transports the goods directly to the WMS-assigned location within the racking system for e-commerce, all without human intervention for transport or decision-making. Dock dwell time is slashed to a minimum.

<h3>Stage 2: High-Velocity Picking & Replenishment</h3>

A customer order enters the system. The WMS consolidates it with others to create an optimized batch, maximizing pick density. It then transmits precise pick instructions to a picker’s RF terminal or to a pick-to-light system mounted directly on the carton flow racks. The generated pick path is a smooth, logical route that systematically navigates the racking system for e-commerce, completely eliminating backtracking and wasted steps.

Concurrently, the WMS perpetually monitors real-time inventory levels in the forward-pick areas. When stock for a high-velocity SKU dips below a pre-set threshold, it automatically generates a replenishment task. An AGV or a forklift operator is instructed to retrieve a pallet from the reserve selective racking and transport it to the forward pick face, a process often scheduled during off-peak hours to maintain uninterrupted picking efficiency.

<h3>Stage 3: Seamless Consolidation, Packing & Sortation</h3>

Picked items are placed into totes and deposited onto the conveyor system. This network transports them directly to a central consolidation zone where all items for a single order are automatically merged. The completed order is then routed to a packing station. After sealing, the package re-enters the conveyor system, feeding into a high-speed sortation unit. The sorter scans the label and, with precision, diverts the package to the exact dispatch chute designated for its carrier or destination zone. This entire flow is a direct result of the seamless integration between the racking system for e-commerce and the material handling automation.

<h3>Stage 4: Optimized Dispatch & Loading</h3>

At the dispatch bay, packages arrive pre-sorted into roll cages or onto pallets by specific route or carrier. This eliminates the chaotic, last-minute searching and manual sorting that plagues traditional warehouses and creates dispatch delays. Loaders can now quickly and accurately build outbound trailers, ensuring faster truck turn-around times and guaranteeing on-time departures—a critical metric for carrier performance and customer satisfaction.

<h2>The Tangible ROI: Measuring the Impact of Integration</h2

Investing in a sophisticated integrated racking system for e-commerce is a strategic capital decision with a clear, compelling, and measurable financial return that justifies the initial expenditure.

Labor Productivity: By systematically eliminating wasteful travel and automating horizontal transport, businesses routinely achieve a 40% to 70% increase in picks per hour. The labor force is upskilled and redeployed to value-added tasks like quality control and complex kitting, rather than mundane movement.

Order Accuracy: System-directed picking via RF scanners, voice pick, or pick-to-light systems drives accuracy rates to 99.99% and above. This near-perfect accuracy virtually eliminates the substantial costs associated with returns, reshipments, and the administrative overhead of handling customer complaints.

Space Utilization: The strategic implementation of a multi-tier mezzanine or high-density push-back racking system for e-commerce can increase storage capacity by 50% to 150% within the same existing building footprint. This dramatically defers or even eliminates the need for a financially burdensome facility relocation or expansion.

Scalability and Future-Proofing: The inherently modular nature of these integrated racking systems for e-commerce means a business can start with a core automated zone and expand it linearly as sales volumes grow. This phasing strategy protects the initial investment and ensures the storage solution evolves in lockstep with the business.

<h2>Case in Point: Transforming a Regional E-commerce Fulfillment Center</h2>

A recent partnership with a mid-sized fashion retailer in Southeast Asia serves as a powerful testament to the transformation possible. The company was struggling with a 72-hour order cycle during peak season, with their warehouse being a textbook example of disconnected storage.

The Challenge: Managing approximately 8,000 SKUs, a complex mix of hanging garments and folded items. Peak season volumes skyrocketed to 300% of normal capacity. Order accuracy was a concerning 97%, and the daily dispatch cutoff time was constantly being pushed back, delaying customer deliveries and increasing stress.

The Integrated Racking Systems for E-commerce Solution:

Designed and installed a comprehensive two-tier mezzanine system with integrated conveyor passes. The ground floor was dedicated to high-volume activities: receiving, bulk storage, and dispatch.

The mezzanine level housed the entire pick-pack-ship operation, creating a dedicated, optimized environment for order fulfillment.

We implemented high-throughput carton flow racks for fast-moving accessories and folded wear.

Specialized garment flow racks were installed for hanging items, ensuring wrinkle-free and efficient picking.

A network of conveyors moved totes seamlessly from picking zones, to packing stations, and finally to the sortation unit.

The entire physical system was managed by a new, industry-leading WMS that was deeply integrated with the client’s existing ERP software.

The Results, 6 Months Post-Implementation:

Order Cycle Time: Plummeted from 72 hours to an impressive 8 hours.

Daily Order Capacity: Increased by 220% without requiring additional floor space.

Order Accuracy: Rose to an exceptional 99.8%, drastically reducing returns.

Labor Costs: Reduced by 25% despite the significantly higher order volumes, directly attributable to the efficiency gains from the new integrated racking system for e-commerce.

<h2>Future-Proofing Your Warehouse: The Path to Full Automation</h2>

Implementing a robust integrated racking system for e-commerce is the most critical and strategic first step on the path to a fully automated warehouse. The structured, organized, and WMS-directed environment it creates is the absolute prerequisite for the successful implementation of more advanced robotics and automation technologies.

The Bridge to AS/RS and AMRs: A well-planned and installed racking system for e-commerce can be seamlessly converted to support an Autonomous Mobile Robot (AMR) fleet, where robots bring the shelving units to stationary pickers. This same structured layout is also the foundation for a full Automated Storage and Retrieval System (ASRS), where robotic cranes travel within the racking structure itself to retrieve and deliver items, creating a lights-out storage and retrieval process.

Data-Driven Optimization: The immense volume of granular data generated by the WMS and control systems provides a goldmine of insights for continuous improvement. This data allows for dynamic slotting, layout adjustments, and process refinements, enabling the racking system for e-commerce to continuously adapt to evolving sales patterns and consumer demands.

<h2>Conclusion: Your Strategic Advantage Awaits</h2>

In the relentless, fast-paced world of global e-commerce, the battle for customer loyalty and market share is increasingly won or lost within the four walls of the fulfillment center. A fragmented, outdated warehouse storage strategy will inevitably crumble under the pressure of modern consumer expectations for speed and accuracy. Embracing an integrated racking system for e-commerce is far more than a simple equipment upgrade; it is a fundamental re-architecting of a company’s fulfillment logic and operational DNA.

It is the deliberate, expert fusion of physical infrastructure, smart automation, and digital intelligence into a single, cohesive, and highly responsive engine for growth. By synchronizing the entire workflow from receiving to dispatch, businesses unlock unprecedented levels of operational efficiency, dramatically slash operational costs, and construct a scalable, resilient platform that secures a durable competitive edge for years to come. The future of fulfillment is unequivocally integrated, and the time for forward-thinking businesses to build theirs is now.

Frequently Asked Questions (FAQs)

1. How does an integrated racking system specifically help with managing returns, a major e-commerce challenge?

A well-designed integrated racking system for e-commerce streamlines reverse logistics by designating a specific zone, often on a dedicated mezzanine level, for returns processing. Incoming return totes can be conveyed directly to this area. The WMS then efficiently manages the inspection, grading, and restocking workflow, getting sellable items back into the active pick faces of the carton flow racking much faster. This transforms a traditional cost center into a recovered asset, improving inventory turnover and customer satisfaction through faster refunds or exchanges.

2. We have a low ceiling height. Can we still benefit from an integrated approach?

Absolutely. While high ceilings allow for dramatic vertical storage in high-bay racking systems for e-commerce, lower ceilings shift the focus to maximizing cube utilization through high-density systems like push-back racking or mobile pallet racks. The core principle of integration remains paramount: connecting these dense storage systems with efficient horizontal transport like AGVs and optimizing the pick-face layout for minimal travel. This proves that a high-performance integrated racking system for e-commerce is about workflow intelligence and density, not solely dependent on clear height.

3. What is the typical project timeline from design to full operational deployment for such a system?

A project of this scale is executed in disciplined, overlapping phases. Detailed design and engineering planning typically take 4 to 8 weeks. The physical installation of the racking, mezzanines, and conveyors can take 6 to 12 weeks, depending on the complexity and size of the facility. Concurrently, software configuration, WMS integration, and interface development occur. Finally, comprehensive system testing, staff training, and a phased go-live process ensure a smooth transition with minimal operational disruption. Total project durations typically range from 5 to 8 months for a complete turnkey integrated racking system for e-commerce.

4. How do you ensure the WMS communicates effectively with our existing ERP and e-commerce platform?

This systems integration is a critical success factor. Implementation teams use robust, pre-built Application Programming Interfaces (APIs) and established middleware that act as universal translators between different software platforms. Specialists possess extensive experience connecting the WMS that governs the integrated racking system for e-commerce with major ERP platforms (like SAP or Oracle) and e-commerce carts (like Shopify or Magento). This ensures seamless, real-time, and bi-directional data flow for inventory levels, order ingestion, and shipment tracking, creating a single source of truth.

5. Can this system adapt to our unique product types, such as large, bulky items or high-value small electronics?

Yes, professional integration is fundamentally about customization. For large, bulky items like furniture or appliances, the solution might be based on wide-span shelving or cantilever racks, integrated with heavy-duty conveyor lines or forklifts. For high-value small electronics, the design would incorporate secure, caged areas with access control, integrated with secure tote-based conveyors and detailed, lot-level tracking within the WMS. The principle remains consistent: first, tailor the components of the racking system for e-commerce to the product profile, and then seamlessly connect them into the wider automated workflow to ensure security, auditability, and efficiency.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com