📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Strategic Imperative of Cost-Effective Warehouse Racking Solutions

In the relentless pursuit of supply chain optimization, the warehouse stands as a critical nexus of cost and efficiency. The prevailing notion that substantial productivity gains necessitate seven-figure investments in automation is a dangerous misconception. This comprehensive guide articulates a more strategic path: the implementation of intelligently engineered, cost-effective warehouse racking solutions.

These systems represent the most pragmatic foundation for achieving dramatic efficiency improvements—potentially exceeding 30%—without capital-intensive projects. By delving into system typologies, integration methodologies, and operational principles, this resource demonstrates how targeted investments in storage infrastructure deliver exponential returns through enhanced density, accelerated workflows, and optimized labor utilization. The focus remains on practical, scalable warehouse racking solutions that transform storage areas from cost centers into strategic assets.

The Modern Warehouse Dilemma: Efficiency Demands Versus Budgetary Constraints

Distribution center managers across emerging markets face a universal challenge: escalating throughput requirements colliding with stringent capital expenditure limitations. The warehouse, once viewed as a static repository, now demands dynamic performance capabilities. When storage aisles become congested, pick paths grow inefficient, and vertical space lies fallow, the entire supply chain suffers. The intuitive response—investing in advanced robotics—often remains financially prohibitive for many organizations.

This is where the paradigm of cost-effective warehouse racking solutions creates transformative opportunities. These systems address the core inefficiencies plaguing storage operations through engineering and design, rather than through complex digitalization. A meticulously planned warehouse racking solution does more than just store goods; it orchestrates product flow. It minimizes non-value-added travel, maximizes every cubic foot of available space, and creates an ergonomic environment that boosts personnel productivity. For operations in Southeast Asia, Latin America, and other growth regions, these warehouse racking solutions provide the essential upgrade path—delivering immediate performance lifts while building a foundation for future technological integration.

Quantifying the Efficiency Dividend: The Anatomy of a 30% Performance Gain

A 30% efficiency gain is not a marketing abstraction; it is a composite metric derived from tangible operational improvements. Senior logistics executives rightly demand a detailed breakdown of such claims. The performance uplift from superior warehouse racking solutions materializes across several key performance indicators (KPIs).

A primary contributor is the radical reduction in order picking cycle times. By implementing warehouse racking solutions that incorporate velocity-based slotting (ABC analysis), travel distance per order can be curtailed by 25% or more. When pickers no longer traverse the entire facility for a single item, but instead access concentrated zones of high-demand SKUs, productivity soars. Furthermore, warehouse racking solutions designed for optimal density directly increase storage capacity by 30-50%, directly offsetting the costs of external storage or facility expansion. This is a direct financial saving.

Labor cost reduction, often amounting to a 10-15% saving, is another critical dividend. Streamlined workflows within intelligently configured warehouse racking solutions reduce redundant motion and fatigue. The ergonomic benefits of these warehouse racking solutions also lower the incidence of workplace injury and staff turnover, delivering indirect cost advantages. Finally, the accuracy inherent in well-organized warehouse racking solutions—where every item has a designated, logical location—dramatically reduces mis-picks and associated reverse logistics costs. In aggregate, these improvements consistently deliver a 30% or greater total efficiency enhancement, making the case for cost-effective warehouse racking solutions financially compelling.

Foundational Design Philosophies for High-Performance Storage Systems

The efficacy of any storage system hinges on its adherence to core material handling principles. The most successful warehouse racking solutions are not random assemblages of steel; they are physical manifestations of sound operational logic.

The Cubic Space Utilization Doctrine

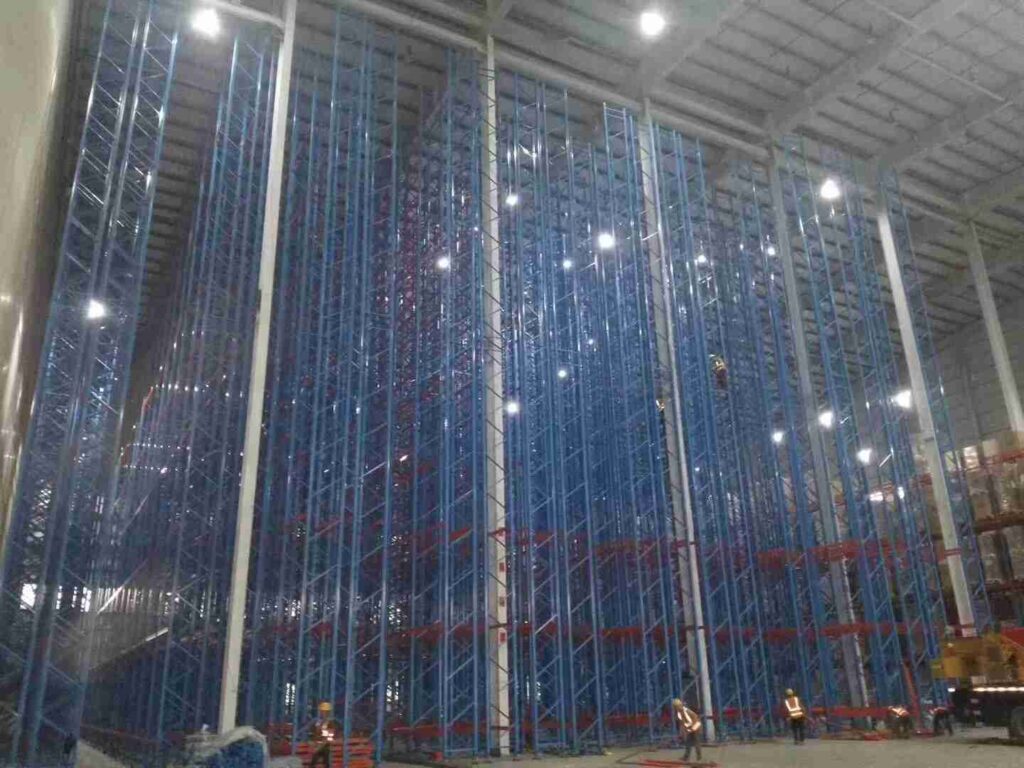

The most egregious waste in many warehouses is the neglect of vertical space. Capital-intensive floor area is squandered when storage rises only 12 feet in a 30-foot clear-height building. Modern warehouse racking solutions are fundamentally engineered to safely conquer this air rights territory. This doctrine asserts that the total cubic volume of the facility is the primary asset to be optimized. Whether through taller selective racking, double-deep configurations, or drive-in systems, the best warehouse racking solutions turn unused volume into productive inventory capacity. This principle is the cornerstone of all cost-effective warehouse racking solutions.

The Goods-to-Person Workflow Optimization Principle

While full automation achieves this with robots, it is possible to approximate the principle affordably. The goal is to minimize the travel time of personnel. This is achieved by warehouse racking solutions that bring goods to the picker in a logical, sequential manner. Flow rack systems (pallet flow and carton flow) are the quintessential example of this principle in action. They are a class of warehouse racking solutions that use gravity to present the next item at the point of pick, creating a dramatic consolidation of workflow and a significant reduction in walking. This principle is vital for designing warehouse racking solutions that boost productivity.

The Inherent Flexibility and Scalability Mandate

A static storage system is a liability in a dynamic market. The most robust warehouse racking solutions are designed for evolution. They feature beam levels that can be repositioned without tools, components that can be reconfigured, and layouts that can be expanded linearly. This adaptability ensures that the warehouse racking solutions implemented today will not become obsolete tomorrow. This future-proofing is a critical aspect of the long-term value proposition of cost-effective warehouse racking solutions, protecting the capital investment against operational changes.

The System Portfolio: An In-Depth Analysis of Engineered Storage Solutions

The market offers a diverse array of warehouse racking solutions, each engineered for specific operational profiles. Selecting the correct typology is paramount to achieving the targeted efficiency gains.

Selective Pallet Racking: The Gold Standard of Accessibility

As the most ubiquitous form of storage, selective pallet racking offers direct, unimpeded access to every single pallet location. This makes it an exceptionally versatile component of modern warehouse racking solutions.

Efficiency Mechanics: The system’s efficiency is derived from its simplicity and compatibility with Warehouse Management System (WMS) directed operations. When a WMS provides optimized put-away and picking paths, selective racking transforms into a highly dynamic tool. It is the ideal platform for warehouse racking solutions handling a vast number of SKUs where random access is a requirement.

Cost-Effectiveness Analysis: Due to its standardization and competitive global supply chain, selective racking remains one of the most cost-effective warehouse racking solutions on a per-position basis. For long-term durability and safety, industry leaders often recommend structural racking over roll-formed variants for main storage aisles. Its reconfigurable nature ensures that these warehouse racking solutions can evolve with inventory needs, delivering a superior lifespan and return on investment.

Drive-In and Drive-Through Racking: The Density Maximizers

For operations dominated by high-volume storage of a limited number of SKUs—such as for seasonal products or raw materials—these warehouse racking solutions offer unparalleled storage density.

Efficiency Mechanics: By drastically reducing the number of access aisles, these warehouse racking solutions can increase storage density by up to 75% compared to selective layouts. Forklifts operate within the rack structure itself, storing pallets in multiple-depth lanes. Drive-through configurations, with access from both ends, facilitate superior FIFO (First-In, First-Out) management for time-sensitive goods.

Cost-Effectiveness Analysis: While the cost per pallet position is higher, the radical reduction in the facility’s footprint required for a given volume makes these warehouse racking solutions incredibly cost-effective on a cost-per-stored-pallet basis. They represent a strategic trade-off, sacrificing some accessibility for massive gains in space utilization, which is often the most expensive operational overhead.

Pallet and Carton Flow Racking: Gravity-Powered Automation

This category represents the intersection of static racking and automation, offering a high-impact, medium-technology option among warehouse racking solutions.

Efficiency Mechanics: These warehouse racking solutions use inclined shelves with wheel or roller tracks. Product is loaded from the rear and moves by gravity to the front pick face. This enforces perfect FIFO and creates a high-density, high-velocity picking zone. Pickers remain stationary, and products flow to them, which can slash picking time and errors by over 30%. This is one of the most effective warehouse racking solutions for case picking operations.

Cost-Effectiveness Analysis: Flow systems command a premium over static shelving, but their cost is a small fraction of a fully automated retrieval system. The return on investment is often remarkably swift, driven by direct labor savings and accuracy improvements. For businesses seeking a transformational upgrade without a multi-year payback period, these warehouse racking solutions are frequently the optimal choice.

Mezzanine Systems: The Vertical Expansion Solution

When floor space is exhausted, the most logical warehouse racking solution is to add a second tier. Mezzanines are structural platforms that create new, usable levels within the existing building envelope.

Efficiency Mechanics: These warehouse racking solutions instantly double or triple operational square footage without the need for construction. The new space can host bulk storage, value-added processing (kitting, labeling), or even office functions, freeing the prime ground-level space for high-velocity activities.

Cost-Effectiveness Analysis: On a pure cost-per-gained-square-foot basis, mezzanines are arguably the most cost-effective warehouse racking solutions for capacity expansion. The investment is substantially lower than the cost of new construction or leasing additional warehouse space. They are a permanent capital improvement that enhances the value and functionality of the entire facility.

The Synergistic Ecosystem: Integrating Racking with Scalable Technologies

The highest-return projects are those where physical warehouse racking solutions are seamlessly integrated with scalable digital and mechanical technologies. This creates a synergistic ecosystem where the whole is greater than the sum of its parts.

The Conveyor-Flow Rack Hybrid Model

A powerful synergy is created by combining pallet flow warehouse racking solutions with a simple conveyor system. Full pallets can be conveyed to the rear loading points of the flow racks, while picked cartons are conveyed away from the front to the packing and shipping area. This model creates a continuous, high-speed product flow that minimizes manual transport. These integrated warehouse racking solutions effectively create zones of automation within a broader manual operation, delivering automated-level throughput at a fraction of the cost.

AGVs as the Mobile Link in the Storage Chain

Autonomous Guided Vehicles (AGVs) can serve as the flexible link between different zones of warehouse racking solutions. An AGV can be tasked with automated replenishment of forward-picking areas from bulk storage racks. This eliminates the need for forklift operators to perform repetitive put-away tasks, allowing them to focus on more complex value-added duties. This hybrid approach leverages the flexibility of AGVs with the structured density of warehouse racking solutions, a combination that is both highly efficient and remarkably cost-effective.

The Indispensable Role of the Warehouse Management System (WMS)

A WMS acts as the central nervous system for all warehouse racking solutions. It is the intelligence that dictates the “where” and “when” for every pallet and carton. A modern WMS optimizes put-away locations based on product velocity and cube, generates pick paths that minimize travel, and provides the real-time data needed for continuous improvement of the warehouse racking solutions’ layout. Without a WMS, even the best-engineered warehouse racking solutions operate below their potential. The investment in a capable WMS is a force multiplier for the physical investment in warehouse racking solutions.

The Implementation Roadmap: A Phased Approach to Transformation

Executing a successful warehouse redesign requires a disciplined, phased methodology. Rushing the process leads to costly errors and operational disruption.

Phase 1: Holistic Discovery and Data Analysis: This goes beyond a physical measurement. It involves a deep analysis of at least three months of order history, SKU master data, and receiving patterns. The goal is to understand not just what is stored, but how it moves. This data forms the blueprint for the new warehouse racking solutions.

Phase 2: Digital Twin Simulation and Layout Validation: Prior to procurement, a 3D digital model of the proposed warehouse racking solutions is built. This digital twin is used to simulate product flow, test different scenarios, and identify potential bottlenecks in traffic or capacity. This step de-risks the project significantly.

Phase 3: Phased Physical Implementation and Commissioning: Installation is scheduled in logical phases—often by zone or product category—to ensure ongoing operations can continue with minimal interference. This meticulous approach to deploying warehouse racking solutions demonstrates a commitment to operational continuity.

Phase 4: Organizational Change Management and Training: The success of the new warehouse racking solutions is dependent on user adoption. Comprehensive training sessions and clear standard operating procedure (SOP) documentation ensure that the team is empowered to leverage the new system to its full potential.

Beyond Steel: Complementary Investments for a High-Performance Operation

The performance of warehouse racking solutions is enhanced by complementary investments in infrastructure and technology.

Industrial Floor Marking and Signage: A clearly marked floor with defined travel aisles, staging areas, and safety zones is a low-cost adjunct that dramatically improves the safety and navigability of any warehouse racking solutions layout.

Pick-to-Light and Put-to-Light Systems: For high-velocity picking zones within the warehouse racking solutions, these systems use lights and digital displays to guide operators, reducing errors and training time to near zero.

Ergonomic Packing and Workstations: Positioning adjustable workstations at the terminus of picking zones within the warehouse racking solutions ecosystem reduces physical strain and promotes sustained productivity.

Conclusion: Building a Future-Ready Warehouse on a Foundation of Strategic Racking

The pursuit of warehouse efficiency in a cost-conscious global market demands a focus on fundamentals. The most reliable and accessible path to a 30% or greater performance gain lies not in speculative technological leaps, but in the strategic deployment of intelligently engineered, cost-effective warehouse racking solutions. These systems—from adaptable selective racking to high-density drive-in systems and gravity-flow live storage—provide the structural and operational framework for a faster, denser, and more accurate operation.

By integrating these physical assets with the guiding intelligence of a WMS and the flexible mobility of technologies like AGVs, businesses can construct a logistics operation that is not only supremely efficient today but also strategically poised for the challenges of tomorrow. In the calculus of modern supply chain management, investing in optimized warehouse racking solutions is the most consequential and reliable decision a logistics leader can make.

Frequently Asked Questions (FAQs)

1. How do you approach designing warehouse racking solutions for facilities with low floor load capacities or irregular column spacing?

This is a common challenge in older facilities or multi-story warehouses. Our engineering team begins with a thorough structural assessment. The design of the warehouse racking solutions is then tailored to these constraints. This can involve distributing weight over a larger footprint, using specialized base plates, designing the layout to strategically avoid columns, or even incorporating structural reinforcement into the warehouse racking solutions themselves. There are always cost-effective warehouse racking solutions available for challenging building environments.

2. What is the typical lead time for a large-scale project involving custom warehouse racking solutions?

Lead times are project-dependent but generally follow a predictable sequence. The design and engineering phase typically requires 3-5 weeks. The manufacturing period for the warehouse racking solutions components is usually 6-8 weeks. On-site installation for a large-scale distribution center can be completed within a 2-4 week window, executed in phases to ensure minimal disruption to the client’s ongoing operations.

3. Beyond visible damage, what are the key indicators that our existing warehouse racking solutions require a safety inspection or upgrade?

Subtle signs often precede obvious damage. These include persistent difficulty in positioning pallets, which may indicate slight misalignment; beams that appear level but require shimming; or rust formation in high-humidity environments, which can compromise structural integrity. Any of these signs warrant an immediate professional inspection of your warehouse racking solutions by a qualified engineer.

4. Can your warehouse racking solutions be designed to accommodate a future transition to a fully automated ASRS (Automated Storage and Retrieval System)?

Absolutely. A forward-thinking strategy is a hallmark of our design philosophy. We can design the initial warehouse racking solutions with future automation in mind. This involves ensuring precise aisle dimensions, floor flatness tolerances, and structural specifications that are compatible with major ASRS manufacturers. This proactive approach protects your initial investment and creates a seamless, cost-effective upgrade path when the business case for full automation matures.

5. What specific data should we prepare to help you model the most efficient warehouse racking solutions for our operation?

To build an accurate model, we require your SKU master list (including dimensions, weight, and packaging type), several months of historical order lines/picking data, and receiving reports showing purchase order quantities. Forecasts for future growth and any specific operational challenges (e.g., FIFO requirements, high-value items needing caged areas) are also invaluable. This data allows us to simulate different warehouse racking solutions and provide a data-backed recommendation for the optimal layout.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com