📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Stop Wasting Space! Is Your Continuous Beam Racking Limiting Your Storage Capacity?

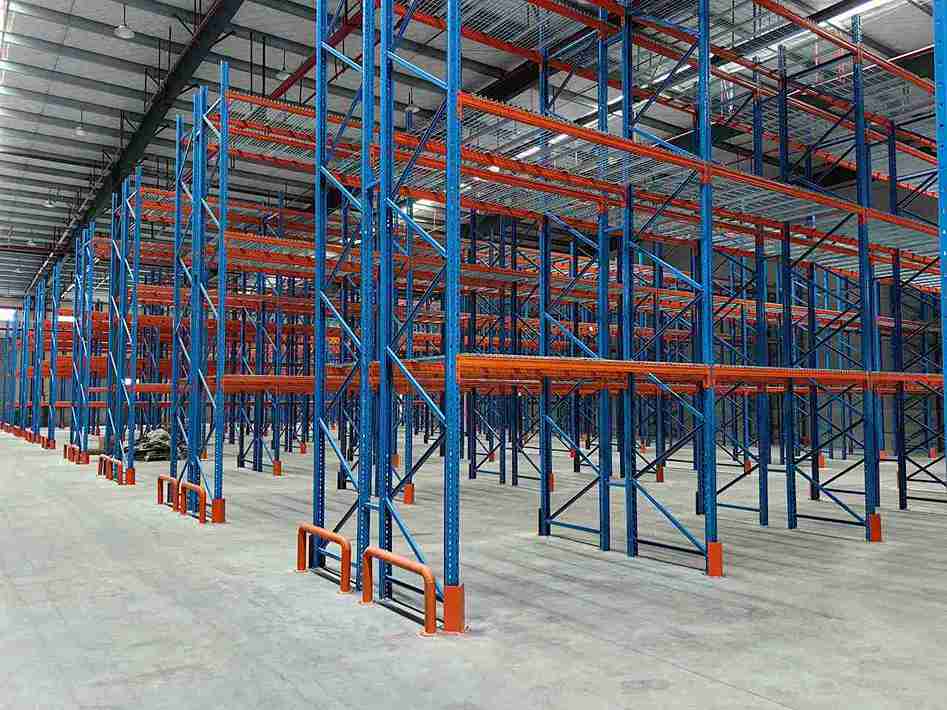

For decades, continuous beam racking has served as the fundamental framework for industrial storage, providing a seemingly straightforward solution for palletized goods. However, a deeper, more critical examination reveals a widespread and costly reality: a significant number of facilities are operating with continuous beam racking systems that are fundamentally constraining their growth, efficiency, and profitability.

The question posed is not merely rhetorical; it is a diagnostic tool for warehouse managers and business owners. When a continuous beam racking installation fails to exploit the full cubic potential of a storage facility, it ceases to be an asset and transforms into a liability. This comprehensive analysis moves beyond basic product descriptions to explore the engineering principles, strategic configurations, and integration methodologies that elevate standard continuous beam racking into a high-performance, space-optimizing powerhouse.

The following sections will deconstruct the hidden costs of inefficient systems, detail the components of a superior continuous beam racking setup, and provide a actionable blueprint for transforming static storage into a dynamic, profit-generating center.

The True Cost of Underperforming Continuous Beam Racking

Many operational leaders view their storage infrastructure as a sunk cost—a fixed element of the warehouse. This perspective is financially myopic. In reality, an under-optimized continuous beam racking system acts as a constant drain on resources, with impacts that ripple across the entire supply chain. The initial capital saved on a less robust continuous beam racking solution is often eclipsed within the first year by compounding operational inefficiencies.

The Cubic Space Paradox: Paying for Air

The most glaring inefficiency of a poorly planned continuous beam racking system is the neglect of vertical space. Warehouses are paid for by the cubic meter, yet many continuous beam racking layouts treat them as two-dimensional floor plans. A standard continuous beam racking installation might leave a meter or more of unused vertical clearance between the top of a stored pallet and the next beam level, or worse, fail to reach anywhere near the building’s eaves.

This wasted air represents a direct financial loss. The company incurs costs for lighting, heating, cooling, and security for space that generates zero revenue. This under-utilization forces premature and capital-intensive expansion into larger facilities. A strategically engineered continuous beam racking system, in contrast, is designed to exploit every permissible inch of vertical height, dramatically increasing storage capacity within the same footprint and deferring multi-million dollar expansion projects.

The Productivity Drain: How Racking Design Dictates Workflow

A continuous beam racking system is not a passive storage entity; it is the primary dictator of material flow within a warehouse. An inefficient continuous beam racking layout creates a cascade of productivity bottlenecks. Aisles that are too wide for the material handling equipment (MHE) fleet waste valuable floor space that could be converted to additional continuous beam racking lanes. Aisles that are too narrow force forklift operators to slow to a crawl, increasing cycle times and elevating the risk of impactful collisions with the continuous beam racking structure.

Furthermore, a non-strategic placement of SKUs within the continuous beam racking bays—such as storing high-turnover items in inconvenient locations—leads to excessive travel distances for order pickers. The design of the continuous beam racking system directly correlates to labor costs, order fulfillment speed, and overall operational throughput.

The Anatomy of a High-Performance Continuous Beam Racking System

To master optimization, one must first achieve mastery over the core components and their engineering. A modern, high-capacity continuous beam racking system is a symphony of precision-engineered parts working in concert.

Upright Frames: The Load-Bearing Backbone

The upright frames form the vertical spine of any continuous beam racking installation. Selecting the correct upright frame is a critical decision that goes far beyond simple height requirements. Key specifications include:

-

Column Gauge and Thickness: The robustness of the steel used directly determines the load-bearing capacity and impact resistance of the continuous beam racking.

-

Profile Design: The specific shape of the column (e.g., open-back, boxed, or structural) influences strength and compatibility with beam connectors and safety accessories.

-

Bracing Pattern: The configuration of the horizontal and diagonal braces between columns is crucial for the overall stability and lateral strength of the continuous beam racking system. An under-specified upright frame compromises the entire integrity of the continuous beam racking structure and poses a significant safety risk.

Pallet Beams and Connectors: The Heart of Flexibility and Safety

The beams are the workhorses of the continuous beam racking system, directly supporting the stored loads. The connection between the beam and the upright frame is arguably the most critical interface in the entire continuous beam racking structure. Modern systems typically employ one of two connector types:

-

Teardrop Connectors: These allow for quick, tool-less adjustment of beam levels, offering unparalleled flexibility for reconfiguring the continuous beam racking layout as inventory profiles change.

-

Bolt-Together Connectors: These provide a fixed, supremely rigid connection, often used in high-capacity, high-impact, or seismic applications where maximum structural integrity is required for the continuous beam racking system.

Each beam end is equipped with a safety lock—a mechanical device that prevents the beam from accidentally dislodging from the upright frame if struck by MHE, a fundamental safety feature in any reputable continuous beam racking design.

Advanced Engineering for Unlocking Maximum Storage Density

This is the transition from basic storage to strategic asset management. Advanced engineering transforms a standard continuous beam racking array into a highly dense, accessible, and customized storage solution.

Pushing Vertical Limits with Custom-Ungineered Uprights

Why constrain a facility with a 10-meter eave height to a standard 8-meter continuous beam racking system? The most effective method for increasing capacity is to build upwards. This often involves commissioning custom-height upright frames for the continuous beam racking system, designed to safely extend to within a safe working distance of sprinklers and lighting. The return on investment for this single engineering decision is profound. Adding even a single meter of effective storage height across a large continuous beam racking installation can yield a 10-15% increase in total pallet positions, a gain achieved without a single brick being laid.

The Science of Aisle Width Optimization

The width of aisles in a continuous beam racking layout is a strategic variable that balances storage density against accessibility. The traditional one-size-fits-all approach is obsolete. The modern methodology involves a detailed analysis of the MHE fleet:

-

Counterbalance Forklifts: Require wider aisles (typically 3.5 meters+), resulting in a lower density continuous beam racking layout.

-

Narrow Aisle (NA) Forklifts: Can operate in aisles as narrow as 2 meters, allowing for a much denser continuous beam racking configuration but requiring a specialized forklift and a skilled operator.

-

Very Narrow Aisle (VNA) Forklifts: These systems, which include man-up and man-down variants, can operate in aisles under 1.8 meters. They often require a guided continuous beam racking environment (wire or rail) for precision, enabling the highest possible density for a continuous beam racking system while maintaining selectivity.

Strategic Beam Level Configuration and Deep-Lane Storage

Uniform beam spacing is a common but inefficient practice in many continuous beam racking setups. A superior approach involves a mixed beam level strategy, where the vertical spacing within the continuous beam racking bay is customized to match the specific heights of different SKU groups. This eliminates the wasted vertical space commonly found in standardized layouts.

For medium-turnover inventory, a 2-deep selective continuous beam racking configuration can be implemented. This variant allows two pallets to be stored on the same beam level, one behind the other, effectively doubling the storage density in that bay while maintaining near-full selectivity, a powerful compromise for the right inventory profile.

Integrating Continuous Beam Racking with Automated Logistics Systems

The frontier of warehouse efficiency lies in automation. A modern continuous beam racking system must be conceived not in isolation, but as an integral component of a potentially automated ecosystem.

Designing for AGV and AMR Interface

Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) interact with continuous beam racking with a level of precision that far exceeds human operation. To ensure seamless integration, the continuous beam racking system must be designed with exacting standards:

-

Dimensional Fidelity: The continuous beam racking structure must be installed with minimal tolerance for deviation. Even slight misalignments can cause retrieval failures for robotic systems.

-

Consistent Pick-Face Geometry: All pick-and-drop locations within the continuous beam racking system must present a uniform interface to the automaton.

-

Enhanced Structural Guiding: Some advanced continuous beam racking designs incorporate subtle physical guides or optical targets to aid in the precise navigation and positioning of AGVs/AMRs. Proactively designing the continuous beam racking for this compatibility is far more cost-effective than retrofitting.

Continuous Beam Racking as the Foundation for AS/RS

In an Automated Storage and Retrieval System (AS/RS), the continuous beam racking is no longer just a storage structure; it becomes the foundational guide and support for the retrieval machinery itself. This demands a paradigm shift in the specification of the continuous beam racking:

-

Ultra-High Precision Engineering: The continuous beam racking must be perfectly plumb and level to within millimeter tolerances over its entire expanse to ensure the smooth operation of the AS/RS cranes.

-

Dynamic Load Capacity: The continuous beam racking must be engineered to withstand not only the static weight of the stored goods but also the dynamic forces imposed by the accelerating, decelerating, and traversing cranes.

-

Integrated Rail Support: The continuous beam racking upright frames are specifically designed with hardpoints and attachments to securely anchor the crane rails, forming a single, unified machine. In this context, the continuous beam racking is a critical, active component of the automation system.

The Non-Negotiable Pillars: Safety and Load Management

Pursuing high density must never compromise safety. A densely packed, high-bay continuous beam racking system concentrates significant mass and value, making rigorous safety protocols and structural integrity paramount.

A Proactive Approach to Rack Protection and Damage Prevention

In a busy warehouse, impacts between MHE and the continuous beam racking are inevitable. A robust safety strategy anticipates these events and mitigates their consequences. Key protective measures for a continuous beam racking system include:

-

Heavy-Duty Column Guards: Installing reinforced steel or ultra-high-molecular-weight polyethylene (UHMWPE) guards around the base of upright frames absorbs impact energy, preventing catastrophic damage to the primary structural members of the continuous beam racking.

-

Aisle-End Barriers: Positioning highly visible, resilient barriers at the end of each continuous beam racking run protects the most vulnerable uprights from lateral impacts.

-

Pallet Supports and Wire Mesh Decking: These accessories, integrated into the continuous beam racking beams, prevent pallets or individual items from being dislodged and falling, protecting both inventory and personnel below.

Comprehensive Understanding of Load Dynamics and Capacity

The load capacity displayed on a continuous beam racking compliance placard is based on ideal, laboratory-like conditions. Real-world warehousing introduces dynamic variables that must be accounted for in the design phase:

-

Eccentric Loading: Pallets that are unevenly loaded or improperly placed create twisting moments on the continuous beam racking beams that standard calculations may not fully capture.

-

Seismic and Environmental Loads: In geographically active regions, the continuous beam racking design must incorporate specific engineering to resist seismic forces. Wind loads can also be a factor in semi-open facilities.

-

Fatigue and Cumulative Damage: The repeated minor stresses from operational vibrations and low-level impacts can, over time, affect the continuous beam racking‘s structural integrity. A professional design includes margins for these real-world factors.

Future-Proofing the Investment: Designing for Adaptability and Growth

A warehouse is a dynamic environment. A superior continuous beam racking system is designed not just for today’s needs, but with the flexibility to adapt to tomorrow’s challenges.

Embracing a Modular and Scalable Philosophy

By adhering to a modular component philosophy, a continuous beam racking system can grow and evolve with the business. This approach ensures that new continuous beam racking bays, additional heights, or complete reconfigurations can be executed efficiently, using compatible components. This protects the capital investment in the continuous beam racking system and provides the operational agility to respond to changes in product mix, seasonality, or market demands without requiring a complete and costly system replacement.

Case Study: Revolutionizing a 3PL’s Distribution Hub with Optimized Continuous Beam Racking

A leading third-party logistics (3PL) provider faced a critical juncture: expand into a new building or radically optimize their existing space. Their existing continuous beam racking was a classic example of underperformance, failing to utilize over 3 meters of vertical space and featuring inefficient, varying aisle widths. A partnership was formed to re-engineer the entire storage infrastructure. The solution involved a complete overhaul of the continuous beam racking system, which included:

-

The installation of custom-engineered, high-capacity continuous beam racking upright frames that extended to the building’s maximum safe height.

-

A strategic zoning of the warehouse, implementing a VNA continuous beam racking zone for slow-movers and a optimized narrow aisle continuous beam racking zone for high-velocity SKUs.

-

A dynamic beam leveling plan for the continuous beam racking, tailored to the specific height profiles of hundreds of different client products.

The Result: The new, high-density continuous beam racking system delivered a 40% increase in pallet locations, slashed average pick times by 18%, and ultimately allowed the 3PL to cancel its expansion plans, saving an estimated $3 million in capital expenditure and securing its competitive position for the next decade.

Conclusion: Re-evaluating Continuous Beam Racking as a Core Strategic Advantage

The evolution from a passive storage fixture to a actively managed, high-performance asset requires a fundamental shift in perspective. A continuous beam racking system is far more than a metal skeleton; it is the central nervous system of warehouse efficiency. Its design and implementation have a direct and measurable impact on operational costs, scalability, throughput, safety, and ultimately, corporate profitability.

By embracing the principles of advanced engineering, strategic integration with automation, and a unwavering commitment to safety and flexibility, businesses can transform their continuous beam racking from a potential bottleneck into their most powerful tool for logistical excellence. The pressing question for any warehouse operator is no longer if they can find a better continuous beam racking solution, but how quickly they can afford to ignore the immense opportunity cost of their current setup.

Frequently Asked Questions (FAQs)

1. What is the realistic payback period for investing in a custom-engineered, high-density continuous beam racking system versus a standard system?

While the upfront cost for a premium continuous beam racking system is typically 20-30% higher, the payback period is often remarkably short, frequently between 18 to 36 months. This calculation factors in the hard cost savings from deferring facility expansion, the reduced cost-per-pallet-stored, and the soft cost savings from productivity gains and reduced damage. A standard continuous beam racking system may have a lower initial price but often carries a higher total cost of ownership over its lifespan.

2. Beyond visible damage, what are the signs that our existing continuous beam racking system may be under-specified or compromised?

Subtle signs often precede major failures. These include beams that appear to be sagging beyond their natural deflection, upright frames that are no longer perfectly plumb, rust formation at connection points, or loose or disengaged safety locks. A more technical sign is persistent difficulty in aligning MHE with the continuous beam racking pallet openings, which can indicate rack movement or settlement. Any of these signs warrant an immediate professional inspection of the continuous beam racking structure.

3. How does the procurement process for a high-capacity continuous beam racking system differ from a standard order?

Procuring a high-performance continuous beam racking system is a consultative and engineering-intensive process, not a simple transaction. It begins with a detailed site survey, including load audits, MHE fleet analysis, and review of building structural drawings. This is followed by a custom design phase using advanced CAD and simulation software to model the continuous beam racking layout for optimal flow and density. The process involves rigorous documentation, including detailed engineering drawings and load capacity charts for the entire continuous beam racking installation.

4. Can a continuous beam racking system be effectively combined with other storage types, like mezzanines or cantilever racking, in the same facility?

Absolutely, and this integrated approach is often the key to maximizing overall facility efficiency. A continuous beam racking system can seamlessly interface with a mezzanine, using the continuous beam racking structure for support in some designs, to create multi-level storage. Similarly, a continuous beam racking zone for palletized goods can be adjacent to a cantilever racking zone for long loads, creating a unified storage solution. The design must be holistic, ensuring traffic flow and load paths are coherently planned between the different systems and the continuous beam racking areas.

5. What specific questions should we ask our racking supplier to gauge their expertise in high-density, automated continuous beam racking solutions?

To separate basic suppliers from expert partners, ask:

-

“Can you provide a finite element analysis (FEA) report for the proposed continuous beam racking design under dynamic load conditions?”

-

“What is your specific engineering protocol for ensuring our continuous beam racking system is compatible with future AGV/ASRS integration?”

-

“What are the specific tolerances (plumb, level, alignment) you guarantee during the installation of our continuous beam racking system, and how is this verified?”

-

“Can you provide case studies where you have designed a continuous beam racking system achieving a storage density increase of over 35%?”

Their responses will clearly indicate their capability to deliver a sophisticated, high-performance continuous beam racking solution.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com