📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

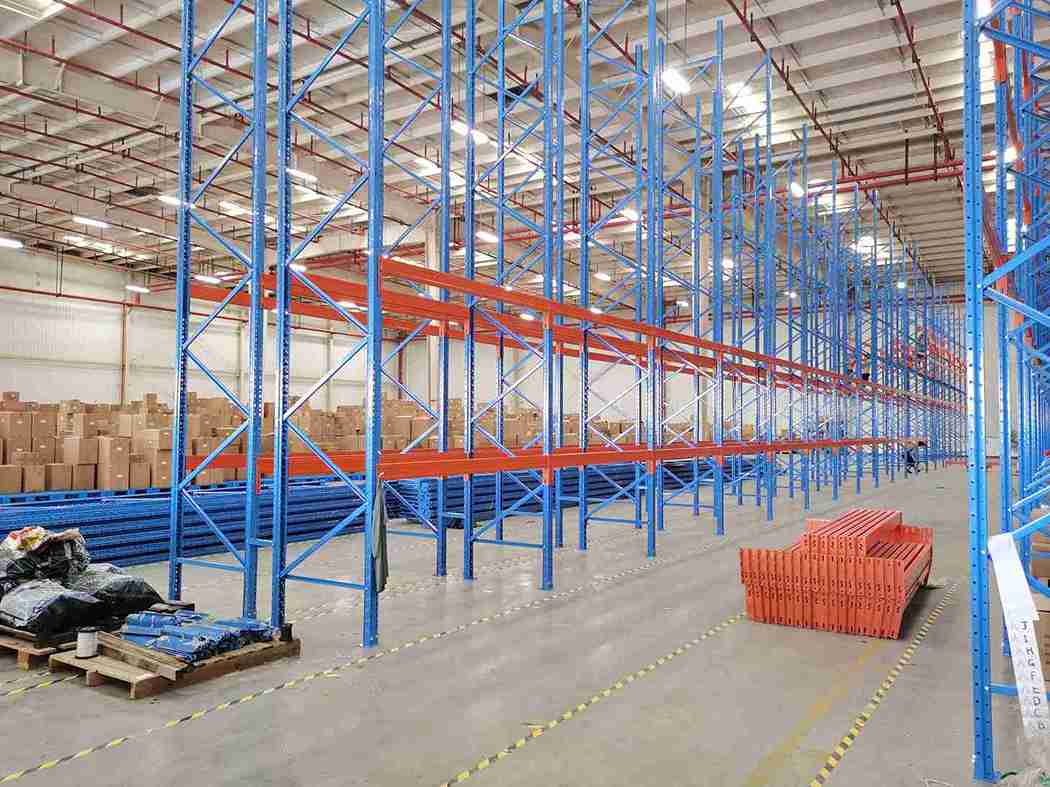

Maximize Storage Efficiency with Roll-formed Beam Racking: The Ultimate Guide for High-Density Warehouses

In the high-stakes world of modern logistics, warehouse managers and operations directors face a constant, pressing challenge: doing more with less space. The exponential growth of e-commerce, coupled with rising real estate costs, has made high-density storage not just an advantage but a necessity for survival and growth. At the very heart of this storage revolution lies a critical, often underappreciated component: roll-formed beam racking.

This is not merely a piece of hardware; it is the engineered backbone of an efficient, safe, and scalable storage operation. For companies navigating the competitive landscapes of Southeast Asia, the burgeoning markets of Africa, or the industrial hubs of Latin America, understanding and implementing the right roll-formed beam racking system is a decisive strategic move. This comprehensive guide delves deep into the engineering, application, and economic superiority of roll-formed beam racking, positioning it as the indispensable solution for any enterprise serious about maximizing storage efficiency and driving down operational costs.

The following analysis provides a masterclass in why roll-formed beam racking consistently outperforms alternatives, offering a clear pathway for businesses to optimize their storage infrastructure from the ground up.

The Engineering Superiority of Roll-Formed Beam Racking

The term “roll-formed” refers to a specific, high-precision manufacturing process that fundamentally differentiates this class of roll-formed beam racking from its hot-rolled or structural counterparts. This cold-forming process involves feeding a continuous coil of high-strength steel through a series of progressively shaped rollers. Each station in this mill gradually bends the steel into a complex, closed-section profile without applying heat, resulting in a beam of exceptional consistency and strength.

Precision and Consistency: The Hallmarks of Quality

The manufacturing precision inherent in producing roll-formed beam racking cannot be overstated. Because the process is continuous and computer-controlled, every meter of roll-formed beam racking produced is identical. This uniformity is critical for the safety and integrity of a high-bay warehouse. It ensures that the load-bearing capacity is predictable and consistent across every single beam in the facility, eliminating the weak points that can plague inconsistently manufactured products. For a warehouse manager, this translates to unwavering confidence in their storage system’s reliability.

The Unbeatable Strength-to-Weight Ratio

The geometry of a roll-formed beam racking profile is a marvel of engineering. The cold-forming process allows for the integration of strategic vertical stiffeners and reinforcing ribs within the beam’s cross-section. These features act like the flanges on an I-beam, dramatically increasing the beam’s moment of inertia and resistance to bending under load. The result is a component that offers an exceptional strength-to-weight ratio. A beam from a high-quality roll-formed beam racking system can support immense palletized loads while itself being relatively lightweight, simplifying handling during installation and future reconfiguration. This efficient use of material is a direct contributor to the overall cost-effectiveness of roll-formed beam racking.

Durability and Surface Protection for Longevity

The cold-forming process preserves the structural integrity of the steel. Unlike hot-rolling, it does not create a scale on the surface, providing a perfectly clean and uniform substrate for coating. Premium roll-formed beam racking is typically finished with a multi-stage pretreatment (e.g., phosphating) followed by a tough electrostatic epoxy-polyester powder coat. This creates a finish that is highly resistant to chipping, scratching, and corrosion, which is a vital consideration for warehouses operating in the humid climates of Southeast Asia or the saline-air environments of coastal Middle Eastern and Latin American ports. This durability ensures that a roll-formed beam racking system maintains its structural and aesthetic integrity for decades.

Why Roll-Formed Beam Racking is the Default Choice for High-Density Applications

High-density storage is a systematic approach to maximizing the number of pallet positions within a given footprint. It is a philosophy that demands more from its core components than standard storage, and roll-formed beam racking is uniquely equipped to deliver.

Maximizing Cubic Space through Vertical Storage

The most straightforward way to increase density is to build upwards. The inherent strength and design flexibility of roll-formed beam racking make it the ideal solution for very-narrow-aisle (VNA) and high-bay applications. The predictable load capacity of this roll-formed beam racking allows engineers to design systems that confidently reach heights of 30, 40, or even 50 feet, fully utilizing the building’s cubic volume. Furthermore, the easy adjustability of roll-formed beam racking means that vertical beam levels can be fine-tuned to match the exact height of palletized goods, eliminating wasted inches of vertical space that, over hundreds of racking bays, amount to a significant loss of potential storage.

The Foundation of Selective Pallet Racking

Selective pallet racking, which provides direct access to every pallet, remains the most versatile and widely used system globally. Its efficiency is entirely dependent on the beam-upright interface. The quick-connect safety locks—often a torsion bar or a patented latch system—integral to roll-formed beam racking allow for rapid, tool-less reconfiguration. This enables warehouse managers to adapt their layout to changing inventory profiles—converting a bay from full-pallet storage to case-picking, for example—without downtime or specialized labor. This operational agility, provided by a robust roll-formed beam racking system, is a direct source of competitive advantage.

Superior Performance in Dynamic Environments

Warehouses are not static. They are dynamic environments subject to constant impacts from material handling equipment. The design of roll-formed beam racking often includes a thicker wall thickness at the connection points, the area most vulnerable to impact. This inherent robustness, combined with optional protective accessories like column guards and end-of-aisle protectors, makes a system built with roll-formed beam racking more resilient to the rigors of daily operation, reducing maintenance costs and downtime.

Advanced Applications: Roll-Formed Beam Racking in Complex Storage Systems

The utility of roll-formed beam racking extends far beyond simple selective racking. Its reliability and engineered performance make it a critical component in more complex, high-density storage solutions.

The Critical Role in Narrow-Aisle and VNA Systems

When aisle widths are reduced to less than 6 feet to maximize storage density, the margin for error disappears. The precision and rigidity of roll-formed beam racking are non-negotiable in these environments. The consistent dimensions and minimal deflection of the roll-formed beam racking provide the stable, predictable structure that VNA turret trucks and order pickers require to operate safely and efficiently at high speeds, mere inches from the racking face. Any inconsistency in the racking could lead to a catastrophic collision.

Supporting Push-Back Rack and Drive-In Rack Systems

These high-density, LIFO and FIFO systems place unique demands on the racking structure. In push-back rack systems, the roll-formed beam racking must support the dynamic loads of carts moving on inclined rails. In drive-in rack systems, the beams must withstand the lateral forces of forklifts driving into the rack structure itself. The multi-directional strength and robust connection details of high-quality roll-formed beam racking are essential for the long-term reliability and safety of these demanding applications.

The Structural Core for Mezzanine Floors

When floor space is exhausted, creating a mezzanine level is a logical step. Roll-formed beam racking is frequently employed as the primary support structure for these multi-tiered systems. The proven load-bearing capacity and engineering data behind roll-formed beam racking make it a trusted and cost-effective choice for creating additional levels for value-added services, bulk storage, or office space, effectively doubling the usable area within the same footprint.

The Seamless Integration of Roll-Formed Beam Racking and Warehouse Automation

The future of logistics is automated, and the physical infrastructure must be prepared. Roll-formed beam racking is not just compatible with automation; it is a fundamental enabler, providing the precise and reliable physical interface that automated systems demand.

Precision for AGVs and Autonomous Mobile Robots (AMRs)

Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) navigate based on a digital map of the warehouse. This digital twin relies on extreme consistency in the physical world. The tight dimensional tolerances and unwavering consistency of roll-formed beam racking ensure that when a robot is programmed to retrieve a pallet, the pallet is in the exact expected position every single time. This precision, inherent in a well-designed roll-formed beam racking system, minimizes mis-picks, system errors, and damage to both the robot and the racking, maximizing the return on investment in automation.

The Interface with Automated Storage and Retrieval Systems (AS/RS)

In a unit-load AS/RS, the storage and retrieval machine (S/RM) must interact with the pallet and the racking with millimeter precision. The clean, consistent, and robust profile of roll-formed beam racking provides an ideal surface for the S/RM’s shuttle or forks to operate against. The system’s overall rigidity, derived from the strength of its roll-formed beam racking components, prevents any significant rack sway that could interfere with the crane’s high-speed movements, ensuring smooth and reliable operation 24/7.

Enabling the Lights-Out Warehouse

In fully automated, “lights-out” facilities, human intervention is minimal to non-existent. The storage infrastructure must be 100% reliable. The predictable performance, proven durability, and integrated safety locks of roll-formed beam racking make it the only logical choice for such mission-critical environments. A failure in the roll-formed beam racking in a lights-out warehouse could halt the entire supply chain for hours or days, making the investment in superior roll-formed beam racking a critical risk mitigation strategy.

A Data-Driven Framework for Customizing Your Roll-Formed Beam Racking Solution

Deploying a world-class storage system is not about selling products; it is about engineering solutions. A truly custom roll-formed beam racking configuration requires a deep, data-driven understanding of a client’s unique operational profile.

The Indispensable Warehouse Audit and Analysis

The first step in specifying the optimal roll-formed beam racking system is a comprehensive operational audit. This involves a detailed analysis of:

-

SKU Profiling: Categorizing inventory by dimensions, weight, turnover velocity (ABC analysis), and special handling requirements.

-

Pallet & Load Specifications: Documenting the type, condition, dimensions, and maximum/average weight of all unit loads.

-

Material Handling Equipment (MHE) Profile: Analyzing the fleet of forklifts (reach trucks, counterbalance, VNA) to determine aisle width requirements and identify necessary impact protection for the roll-formed beam racking.

-

Throughput and Growth Projections: Understanding daily put-away and picking volumes, as well as forecasting future business growth to ensure the roll-formed beam racking system is designed for scalability.

Advanced Load Capacity and Seismic Engineering

This is where engineering excellence separates a adequate system from an exceptional one. For any roll-formed beam racking project, detailed structural calculations are performed based on the specific load data and the warehouse’s geographic location. Facilities in seismically active zones, such as parts of Central Asia, South America, or the Philippines, require a completely different engineering analysis than those in more geologically stable areas. Reputable providers design their roll-formed beam racking systems with significant safety factors and in full compliance with international standards like RMI (Rack Manufacturers Institute) and FEM (Federation Européenne de la Manutention).

Strategic Layout and Flow Optimization

Using advanced CAD and warehouse simulation software, the data from the audit is transformed into a dynamic layout model. This model optimizes the placement of the roll-formed beam racking to create the most efficient material flow, minimizing travel times for both order pickers and replenishment vehicles. The goal is to integrate the roll-formed beam racking system seamlessly into the workflow, not just to install it in the available space.

The Compelling Economic Case: Analyzing the Total Cost of Ownership

The initial purchase price of racking is a poor indicator of its long-term value. A sophisticated financial analysis must consider the Total Cost of Ownership (TCO), where roll-formed beam racking consistently demonstrates its superiority.

Initial Investment Versus Long-Term Value

While the price per beam is a factor, the long-term economic benefits of roll-formed beam racking are profound:

-

Space Savings: The high-density capabilities of a well-designed roll-formed beam racking system directly reduce the cost per pallet position, often saving enough on real estate costs to justify the investment alone.

-

Operational Efficiency Gains: Faster picking times, easier reconfiguration, and improved inventory visibility all contribute to a lower cost of operation, which is a direct result of a well-planned roll-formed beam racking layout.

-

Reduced Maintenance and Reconfiguration Costs: The durability and easy adjustability of roll-formed beam racking mean lower costs for repairs and future layout changes compared to more primitive systems.

Mitigating the Catastrophic Cost of System Failure

The true cost of a racking collapse is not just the damaged inventory and equipment; it is the complete stoppage of operations, potential liability, and reputational damage. The engineered safety, proven reliability, and robust construction of a quality roll-formed beam racking system are a form of operational insurance. Investing in certified and properly engineered roll-formed beam racking is a fundamental risk management decision for any serious business.

Upholding Global Standards and Safety with Roll-Formed Beam Racking

Safety is the non-negotiable foundation upon which all warehouse operations are built. A roll-formed beam racking system must be designed, installed, and maintained to the highest possible safety standards.

Certification and Compliance: RMI and FEM Standards

Leading manufacturers design their roll-formed beam racking to meet or exceed the rigorous standards set by bodies like the RMI and FEM. These standards govern material quality, manufacturing tolerances, design methodologies, and testing protocols. Specifying a roll-formed beam racking system that is RMI or FEM compliant provides an independent verification of its quality and safety, a critical consideration for multinational companies with operations across Southeast Asia, the Middle East, and beyond.

Implementing a Proactive Safety Culture

A roll-formed beam racking system is only as safe as the processes around it. Reputable providers supply more than just hardware; they provide the framework for safety:

-

Load Application and Rack Capacity (LARC) Plaques: These are affixed to every bay of the roll-formed beam racking, clearly stating the maximum permissible load per level.

-

Comprehensive Inspection Guides and Training: Clients are trained on how to conduct regular inspections of their roll-formed beam racking to identify and report damage like bends, cracks, or impacts.

-

A Full Suite of Safety Accessories: A range of products, including heavy-duty column guards, end-of-aisle protectors, and pallet safety bars, are available to integrate with the roll-formed beam racking and mitigate the risk of forklift impact.

The Intelligent Future: Roll-Formed Beam Racking in the IoT-Enabled Warehouse

The next evolutionary leap in warehouse management is the convergence of physical infrastructure with digital intelligence, and roll-formed beam racking is poised to be a key platform for this transformation.

The concept of “smart racking” involves embedding sensor technology directly into the roll-formed beam racking structure. Imagine IoT weight sensors on each beam level of the roll-formed beam racking, providing real-time inventory data to the WMS. Or impact detection sensors that immediately alert managers to a forklift collision, pinpointing its exact location within the roll-formed beam racking matrix. This data creates a “digital twin” of the warehouse, enabling predictive analytics, optimizing space utilization in real-time, and revolutionizing inventory accuracy. The rigid, predictable, and robust nature of roll-formed beam racking provides the ideal physical foundation to deploy this sensor network reliably. This intelligent evolution of roll-formed beam racking will form the core of the truly responsive, data-driven warehouses of the future.

Conclusion: Building the Foundation for Logistical Excellence

In conclusion, the selection of a warehouse’s storage system is one of the most consequential decisions an operations leader will make. It is a strategic choice that impacts efficiency, safety, scalability, and the bottom line for years to come. The evidence, from engineering principles to economic analysis, overwhelmingly supports roll-formed beam racking as the superior solution for high-density storage challenges.

Its precision, strength, adaptability, and seamless integration with automation make it the only logical foundation for a modern, competitive logistics operation. For businesses looking to expand their capacity, enhance their efficiency, and future-proof their operations across global markets, the path forward is clear. A custom-engineered roll-formed beam racking system is not an expense; it is a transformative investment in logistical excellence.

Frequently Asked Questions (FAQs)

1. How does the design of the beam end connector in roll-formed beam racking contribute to overall system safety?

The beam end connector is a critically engineered component in roll-formed beam racking. High-quality systems feature a positive, mechanical safety lock—such as a torsion bar that expands within the upright column or a patented latch mechanism. This design ensures that the beam cannot become accidentally dislodged from the upright, even under significant upward force or impact. This failsafe mechanism is a fundamental safety feature that distinguishes professional-grade roll-formed beam racking from inferior products.

2. Can roll-formed beam racking be effectively used in environments with extreme temperature fluctuations, such as in the Middle East or Central Asia?

Yes, high-quality roll-formed beam racking is designed to perform in a wide range of environmental conditions. The cold-forming process and high-strength steel used ensure dimensional stability. The powder-coat finish offers excellent resistance to thermal cycling, preventing cracking or peeling that can occur with inferior paints. For uninsulated warehouses in desert climates, the roll-formed beam racking‘s performance remains uncompromised.

3. What are the key differences between roll-formed beam racking and structural racking, and when is one preferred over the other?

Roll-formed beam racking is created by cold-forming steel coil into a custom profile, resulting in a lightweight, high-strength component with excellent adjustability. Structural racking typically uses hot-rolled C-channel or I-beam sections that are welded together; it is very strong but heavier, less adjustable, and often more expensive. Roll-formed beam racking is preferred for the vast majority of warehouse applications due to its cost-effectiveness, flexibility, and precision. Structural racking is typically reserved for static, ultra-heavy-duty applications where reconfiguration is not anticipated.

4. How does your company ensure the quality and consistency of the steel used in your roll-formed beam racking systems?

Partners work exclusively with certified mills that provide material test certificates for every batch of steel. The steel chemistry and mechanical properties (yield strength, tensile strength) are verified upon receipt. This rigorous sourcing standard ensures that the raw material for every piece of roll-formed beam racking meets the specified engineering requirements, guaranteeing consistent performance and safety.

5. What is the typical process for a multinational corporation to procure and install a large-scale roll-formed beam racking system across multiple countries?

The process is managed as a turnkey international project. It begins with a centralized audit and design phase to ensure a standardized solution. Then, the roll-formed beam racking is manufactured and shipped directly to the various port destinations. The company leverages a network of vetted, trained local installation partners in each country (e.g., in Vietnam, Saudi Arabia, Chile) who handle the final logistics and erection according to the master installation manual, ensuring consistent quality and safety standards worldwide.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com