📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Maximize Warehouse Efficiency: The Definitive Guide to Advanced Custom Pallet Storage Solutions

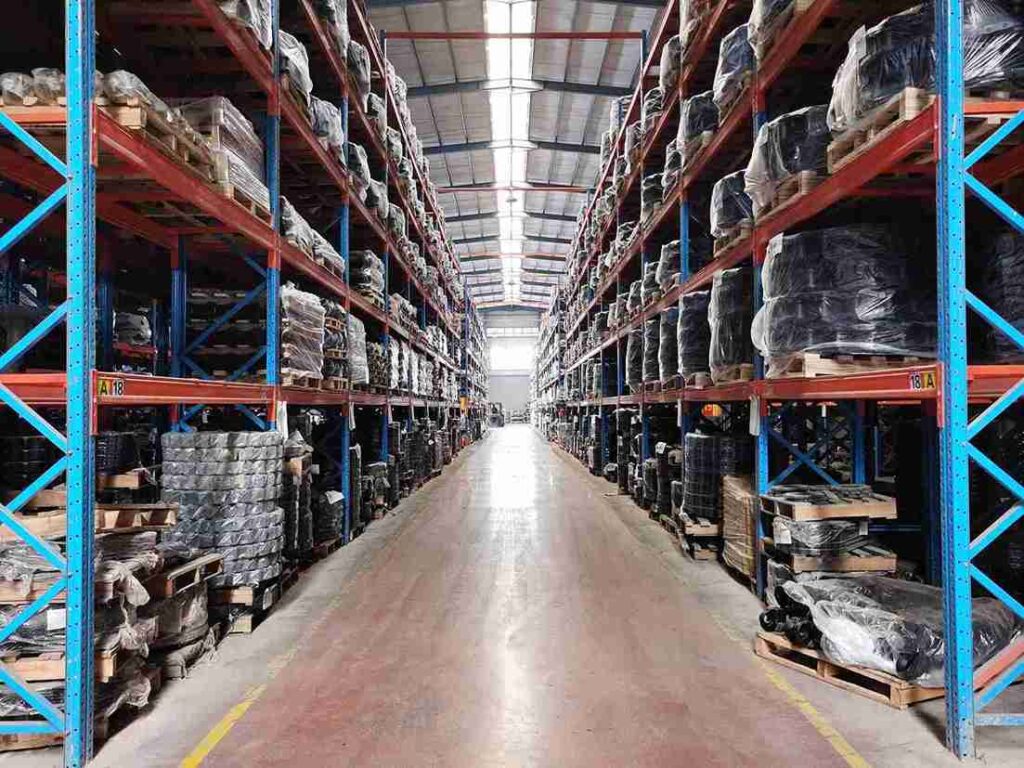

In the relentless engine of global commerce, the warehouse has evolved from a static storage space into the dynamic, pulsating heart of the supply chain. For businesses across the booming industrial landscapes of Southeast Asia, the Middle East, Latin America, and Africa, the pressure to do more with less has never been greater. The central challenge is universal: how to store more product, move it faster, and manage it smarter, all within the four walls of an existing facility.

The solution, proven time and again across diverse sectors from agro-processing to automotive manufacturing, is a fundamental rethinking of pallet storage. This is not about installing generic shelving; it is about engineering a high-performance ecosystem. True, transformative efficiency is unlocked only through meticulously custom pallet storage solutions that are designed from the ground up to align with a company’s unique operational DNA.

This comprehensive guide delves deep into the art and science of creating such systems, moving beyond basic concepts to explore the advanced engineering, strategic integration of robotics, and data-driven design that separates a mere cost center from a formidable competitive asset. The journey to maximize warehouse efficiency begins with a single, pivotal realization: optimal pallet storage is the bedrock upon which all other logistics advancements are built.

The Critical Limitations of Standardized Racking in a Custom World

The allure of a one-size-fits-all pallet storage system is understandable, often driven by a perception of lower initial investment and faster deployment. However, this approach fundamentally ignores the unique fingerprint of every modern warehouse. A facility storing fragile electronics components in Vietnam has vastly different requirements from one handling bulk-packed agricultural goods in Kenya or temperature-sensitive pharmaceuticals in Colombia.

Deploying a standardized pallet storage system in such diverse environments is a recipe for entrenched inefficiency. These generic systems create a cascade of hidden costs that silently erode profitability. They often fail to perfectly utilize a building’s clear height, leaving expensive cubic air space empty. Their fixed dimensions can create awkward aisle widths that hinder the maneuverability of both traditional forklifts and modern AGVs, leading to longer travel times and increased risk of product damage.

The very nature of standard pallet storage inhibits seamless scalability, making it difficult and costly to integrate future technologies like automated storage and retrieval systems (AS/RS). A custom pallet storage solution, in stark contrast, is conceived from a deep forensic analysis of a business’s specific inventory profile, material flow patterns, peak season demands, and long-term strategic growth plans. It is a proactive, strategic investment designed to eliminate waste in every form—space, time, and labor.

Quantifying the Hidden Cost of Inefficient Pallet Storage

To fully appreciate the value of a custom pallet storage solution, one must move beyond upfront price tags and examine the total cost of ownership of an inadequate system. The financial drain of inefficient pallet storage is often hidden in plain sight within operational budgets. Consider the direct impact on labor: a poorly designed layout forces forklift operators to take longer, more complex routes to complete each pick or put-away cycle.

This translates directly into higher fuel or battery costs and reduced overall throughput. Furthermore, a non-optimized pallet storage environment complicates inventory management. When SKUs are not logically positioned based on their turnover rate (a principle known as ABC analysis), cycle counts become more time-consuming and error-prone, leading to stock-outs of fast-moving items and overstocking of slow-movers. The space itself, often the second-largest operational expense after labor, is frequently squandered.

Inefficient pallet storage systems can easily waste between 20% to 40% of a facility’s available cubic volume, space for which the company is paying rent, utilities, and taxes. A custom pallet storage strategy is specifically engineered to recapture this lost value, turning wasted space into productive asset.

The Architectural Blueprint: Core Components of a High-Performance Custom Pallet Storage System

A world-class custom pallet storage system is a symphony of engineered components, each meticulously specified and integrated to perform a specific function within the broader operational workflow. It is a physical manifestation of data-driven decision-making. Understanding these core components is essential for any logistics or operations manager looking to spearhead an efficiency project.

Selective Pallet Racking: Precision-Engineering the Industry Workhorse

While selective racking is the most ubiquitous form of pallet storage, its potential for customization is profoundly underestimated. A truly custom pallet storage approach transforms this simple structure into a high-performance asset. It begins with moving beyond catalog specifications.

Beam capacity, for instance, is not selected from a standard chart but is calculated based on the precise weight and dimensions of each unique unit load, ensuring maximum safety and structural integrity, especially for ultra-dense products in industries like metals or machinery. Frame depth and configuration are manipulated to create hybrid zones within the same aisle, accommodating a mix of pallet sizes without sacrificing space. The integration of specialized accessories is another hallmark of a superior custom pallet storage system.

This includes custom-fitted wire mesh decking to support small, non-palletized items, heavy-duty post protectors designed for the specific impact profile of a site’s vehicle traffic, and integrated aisle markers that sync seamlessly with a Warehouse Management System (WMS) to guide operators with pinpoint accuracy. This level of detail in designing selective pallet storage lays a flawless foundation for all other warehouse activities.

High-Density Storage Systems: The Strategic Conquest of Space

When expansion is impossible or prohibitively expensive, the only direction to grow is inward. High-density pallet storage configurations are the master key to unlocking this internal potential, dramatically increasing capacity within a fixed footprint. The choice between systems is a strategic one, and a custom pallet storage provider acts as a consultant to determine the optimal fit.

Drive-In & Drive-Thru Racking: This LIFO (Last-In, First-Out) pallet storage solution is ideal for high-volume, low-SKU-count environments like cold storage for food or warehousing for bottled beverages. Customization involves engineering the guide rail structure and determining the precise number of pallet depths to balance density with accessibility, all while considering the skill level of local forklift operators.

Push-Back Racking: Offering greater selectivity than drive-in systems, push-back pallet storage operates on a LIFO basis within each lane. Each pallet rests on a nested cart that rides on inclined rails. The customization here is highly technical, involving precise calculations of the cart’s weight, the incline angle, and the roller mechanism to ensure smooth, reliable movement for specific load weights, preventing jams and ensuring operator safety.

Pallet Flow (Dynamic) Racking: As the ultimate FIFO (First-In, First-Out) pallet storage system, pallet flow is critical for industries with perishable goods or strict lot-date control, such as pharmaceuticals or chemicals. The engineering is exceptionally nuanced. Specialists must calculate the exact wheel pitch, track angle, and braking system based on the pallet’s bottom condition, the product’s weight distribution, and its susceptibility to damage. A miscalculation in this type of pallet storage system can lead to catastrophic jams or dangerously fast-moving pallets.

Narrow Aisle & Very Narrow Aisle (VNA) Solutions: The Precision Engineering of Space

The most direct method to increase pallet storage capacity is to reduce the space dedicated to aisles. A custom narrow aisle system is an exercise in precision engineering, far removed from simply placing racks closer together. The design process for this advanced form of pallet storage involves a sophisticated analysis of the interplay between equipment and infrastructure.

Aisle width is not a standard measurement but a calculated value derived from the turning radius of the specific narrow aisle forklift or order picker, combined with pallet overhang and critical safety tolerances. The goal is to create the tightest possible aisle that remains perfectly safe and fully operational. For VNA systems, which often rely on wire or rail guidance for operator-free AGVs, the pallet storage racking itself becomes part of the guidance system. Its installation must be executed with laser-guided precision, as any deviation can disrupt the entire automated process.

This synergy between the physical pallet storage structure and the automated vehicle is a hallmark of a world-class installation. Furthermore, to exploit every cubic foot of available space, a custom pallet storage design will often integrate high-density racking with custom mezzanine floors, effectively creating a multi-story storage facility within a single building envelope.

The Synergy of Steel and Software: Integrating Custom Racking with Automation

The modern warehouse is a cyber-physical system where the physical pallet storage infrastructure must communicate flawlessly with digital control systems and robotic labor. In this environment, the racking is no longer a passive entity; it is an active, intelligent participant in the material flow. This integration makes the case for a custom pallet storage approach more compelling than ever.

Designing for Robotics: The AGV-Compatible Pallet Storage Environment

Automated Guided Vehicles (AGVs) and autonomous mobile robots (AMRs) lack the adaptive intuition of a human operator. They cannot compensate for a bent beam or an inconsistently sized pallet opening. Therefore, the pallet storage interface for robotics must be engineered to machine-level tolerances. This involves specifying racking components and overseeing an installation process where tolerances are measured in millimeters.

This flawless consistency ensures that an AGV or unmanned forklift can reliably place and retrieve pallets thousands of times per day without human intervention. The layout of the pallet storage system is also optimized for robotic efficiency, designed to minimize travel time and complex maneuvers. The physical pathway of the robot is, in effect, programmed into the very structure of the pallet storage array. When considering automated storage and retrieval systems (AS/RS), the integration is total.

In these systems, the pallet storage structure is the machine. It must support the rails for the high-speed S/R cranes and be perfectly level and plumb across its entire vast expanse. The dynamic loads imposed by these cranes, with their rapid acceleration and deceleration, demand a custom pallet storage structure of exceptional rigidity and precision, a task far beyond the capability of standardized racking.

The Collaborative Journey: From Initial Consultation to Operational Transformation

The development of a custom pallet storage solution is a collaborative partnership, not a simple transaction. A provider’s “Free Consultation” should be the first step in a rigorous, data-driven process aimed at delivering a tangible return on investment.

Comprehensive Operational Audit and Data Analysis: The process begins with a deep dive into the client’s world. This involves analyzing WMS data to understand SKU velocity (ABC analysis), seasonal inventory fluctuations, and order profiles. Physical walk-throughs and interviews with warehouse staff provide invaluable qualitative data on daily pain points and workflow challenges.

Advanced 3D Modeling and Flow Simulation: Leading providers leverage advanced software to create a dynamic digital twin of the proposed pallet storage environment. This model allows for simulation of material flow under various demand scenarios, identifying and eliminating potential bottlenecks for both current and future-state operations before a single rack is purchased.

ROI-Focused Engineering Proposal: The resulting proposal is more than a quote; it is a business case. It should clearly articulate the projected financial and operational benefits of the new custom pallet storage system, including metrics like increased storage capacity (pallet positions gained), labor savings (reduced travel time per task), and productivity gains (orders picked per hour).

Seamless, Expert Project Management: The installation of a complex pallet storage system must be managed with military precision. A dedicated project manager ensures that every phase—from site preparation and delivery to installation and final safety certification—is executed on schedule and with minimal disruption to the client’s ongoing operations.

Global Proof: Case Studies in Pallet Storage Transformation

The theoretical benefits of a custom pallet storage solution are made concrete through real-world applications. These case studies illustrate the transformative impact across different industries and regions.

Case Study: E-Commerce Fulfillment Center, Southeast Asia: A rapidly growing online retailer was facing a 250% surge in order volume, overwhelming their existing standard pallet storage. The solution was a multi-faceted custom pallet storage system. It featured a high-bay, narrow-aisle pallet storage zone for bulk replenishment, integrated with a multi-level mezzanine and pick modules for high-speed order fulfillment. The result was a 110% increase in pallet storage capacity, a 45% reduction in picker travel time, and the creation of a scalable infrastructure capable of handling projected growth for the next five years.

Case Study: Automotive Parts Distribution, Mexico: A distributor for a global automotive brand struggled with inventory inaccuracy and high labor costs in its deep-lane pallet storage. The implementation of a custom pallet storage system featuring pallet flow racking for high-turnover components and push-back racking for slower-moving parts, all fully integrated with a new WMS, enforced perfect inventory rotation (FIFO). This led to a 99.9% inventory accuracy rate, a 55% reduction in labor hours dedicated to stock selection, and a complete elimination of stock-out incidents for critical fast-moving items.

Conclusion: Positioning Your Warehouse for the Future

In the high-stakes arena of global logistics, standing still is tantamount to moving backward. The warehouse is no longer a passive repository but a critical determinant of supply chain resilience, customer satisfaction, and overall corporate profitability. Investing in a custom pallet storage solution is the most definitive step a company can take to future-proof its logistics operations. It is an investment that pays continuous dividends through denser storage, faster throughput, fewer errors, and a robust platform for the integration of Industry 4.0 technologies.

A generic pallet storage system stores products; a strategically engineered custom pallet storage solution drives growth, enhances agility, and builds an unassailable competitive advantage. The journey to maximize warehouse efficiency is a strategic imperative, and it begins with a commitment to reimagining the very foundation of storage.

Frequently Asked Questions (FAQs)

What is the typical lead time for a large-scale, fully custom pallet storage project involving automation integration?

The timeline for a sophisticated custom pallet storage project is necessarily comprehensive to ensure precision and quality. While a basic selective system may take 4-8 weeks, a large-scale project with high-density pallet storage and automation integration typically requires a 12 to 24-week timeline. This encompasses detailed engineering design, manufacturing of custom components, precise site preparation, and meticulous installation and commissioning. Rushing this process for a custom pallet storage system compromises the precision required for optimal performance, especially with robotics.

2. Our business has unique, non-standard pallet sizes. Can a custom pallet storage system accommodate this?

Absolutely. Accommodating non-standard pallets is a primary reason businesses seek a custom pallet storage solution. Standard systems are designed for common pallet footprints (e.g., 48″x40″). A custom pallet storage provider will engineer the racking beams, frame depths, and decking specifically for your unique pallet dimensions and load weights, ensuring perfect fit, maximum safety, and efficient space utilization. This is a common requirement in specialized industries and specific geographic markets.

3. How does the seismic activity in our region (e.g., parts of Latin America or Southeast Asia) influence the design of a pallet storage system?

Seismic activity is a critical design consideration that fundamentally differentiates a generic pallet storage system from a custom pallet storage solution. In seismic zones, the structural engineering of the pallet storage system must account for dynamic lateral and vertical forces. A professional provider will design the system with specific seismic bracing, connections, and base plate details that meet or exceed the local building codes. This is not an accessory but a core safety feature of the pallet storage structure, ensuring stability and protecting both inventory and personnel.

4. We have a mixed fleet of forklifts and are planning to introduce AGVs. How can our pallet storage system be designed for both?

Designing a hybrid pallet storage environment is a complex but common challenge. The strategy involves creating a layout with designated zones. High-density, narrow-aisle pallet storage zones can be optimized for your specialized AGVs, with racking engineered to machine-level tolerances. Meanwhile, broader aisles in bulk storage or receiving areas can be designed for flexible use by both traditional forklifts and AGVs. The entire pallet storage layout is modeled to ensure smooth traffic flow and minimize interference between the different vehicle types.

5. What kind of ongoing structural integrity checks and maintenance does a high-density custom pallet storage system require?

All pallet storage systems, especially high-density configurations with moving parts, require a formalized inspection and maintenance program. For static racking, this involves scheduled visual inspections for impact damage and a formal annual inspection by a qualified engineer. For dynamic pallet storage systems like push-back and pallet flow, maintenance includes regular inspection and lubrication of carts, and checking rollers, wheels, and brakes for wear. A professional custom pallet storage provider will supply a detailed maintenance manual and often offer ongoing service contracts to ensure the long-term performance and safety of the investment.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com