📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Strategic Imperative: Leveraging Custom Automated Storage and Retrieval System (AS/RS) for Unrivaled Warehouse Dominance in Southeast Asia

The Southeast Asian logistics landscape is in the throes of a historic transformation. For decades, the region’s warehouses operated on a simple principle: more square footage equated to more capacity. This model, reliant on vast spaces, legions of forklifts, and manual labor, is now fundamentally broken. Skyrocketing land costs in commercial hubs like Bangkok, Jakarta, and Manila are eroding profit margins. The relentless surge in e-commerce, fueled by consumer demands for near-instant delivery, has placed unbearable strain on manual picking and packing processes. Concurrently, a tightening labor market makes it increasingly difficult to secure and retain a skilled warehouse workforce. The confluence of these factors signals a terminal decline for the traditional warehouse.

The paradigm is shifting from managing floor space to mastering the cubic volume of a facility. The future belongs to dynamic, intelligent, and three-dimensional storage strategies. At the heart of this revolution is the Automated Storage and Retrieval System (AS/RS), a technological solution that is rapidly transitioning from a capital-intensive luxury for multinationals to a core, ROI-driven necessity for businesses of all scales.

A strategically implemented Automated Storage and Retrieval System (AS/RS) is no longer merely an automation project; it is a comprehensive business strategy for achieving resilience, scalability, and market leadership. This deep-dive exploration will delineate how a custom-engineered Automated Storage and Retrieval System (AS/RS) serves as the most powerful tool for companies to maximize spatial efficiency, slash operational costs, and build an unassailable competitive advantage in the vibrant yet volatile Southeast Asian market.

Deconstructing the Southeast Asian Warehouse Squeeze: The Inefficiency Tax

The symptoms of an outdated warehouse model are palpable for managers across the region. The instinctive reaction to capacity constraints—seeking a larger facility—is a costly and often misguided solution. The core issue is not a genuine lack of space but a critical failure to utilize existing space intelligently. This inefficiency imposes a silent but substantial “tax” on the entire operation.

The Tangible Costs of Spatial and Operational Waste

The financial drain of an inefficient warehouse extends far beyond the monthly lease. A detailed analysis reveals multiple layers of avoidable cost:

The Real Estate Premium: Industrial land prices have seen compound annual growth rates exceeding 10% in key metropolitan areas. Expanding a footprint is a monumental capital commitment. A well-configured Automated Storage and Retrieval System (AS/RS) directly attacks this cost center by radically increasing storage density within the existing building envelope.

The Labor Productivity Gap: In a conventional setup with selective pallet racking, operational studies indicate that forklift operators and order pickers can spend up to 60% of their shift simply traveling. This is a direct inefficiency in payroll expenditure. An Automated Storage and Retrieval System (AS/RS) eliminates non-value-added travel time, channeling human effort into skilled, supervisory, and exception-handling roles.

The Vertical Dimension Penalty: Traditional racking often leaves 40-50% of a building’s air rights unused. Paying for a 10-meter-tall building but only using 5 meters of its height is a profound waste of a rented or owned asset. Every cubic meter of unused vertical space represents a lost opportunity, which a high-density Automated Storage and Retrieval System (AS/RS) is specifically engineered to reclaim.

The Error and Safety Quotient: Manual processes in congested environments are prone to errors—mis-picks, misplaced inventory, and shipping inaccuracies—that trigger expensive reverse logistics and damage brand reputation. Furthermore, congested aisles are a persistent safety hazard, creating bottlenecks and potential liability.

The Human Capital Conundrum: Scarcity and Skill Gaps

The logistics sector is grappling with an acute human capital challenge. Recruiting a certified forklift operator in Ho Chi Minh City or a night-shift warehouse supervisor in Selangor is a protracted and competitive process. A operational model predicated on a large, manual workforce introduces significant volatility through turnover, absenteeism, and the physical limits of human labor. In stark contrast, a robust Automated Storage and Retrieval System (AS/RS) delivers unwavering performance across three shifts, unaffected by fatigue, and operates with sub-millimeter precision, ensuring inventory integrity is maintained 24/7.

Automated Storage and Retrieval System (AS/RS) Demystified: The Architectural Core of the Modern Warehouse

The term Automated Storage and Retrieval System (AS/RS) can evoke images of immense, fully automated high-bay facilities. While that represents one application, the technology is remarkably adaptable. Fundamentally, an Automated Storage and Retrieval System (AS/RS) is an integrated suite of computer-controlled equipment designed for the automatic placement and retrieval of items from specific, defined storage locations. However, a custom Automated Storage and Retrieval System (AS/RS) transcends this basic definition. It represents a solution meticulously architected around a client’s unique operational DNA, including:

Product Profile & Mix: Ranging from small-piece parts in totes to multi-ton pallets of industrial materials.

Throughput Velocity: The required number of storage and retrieval cycles per hour, day, and peak season.

Facility Geometry & Constraints: The specific dimensions, floor-loading capacity, and column spacing of the existing or planned building.

Ecosystem Integration: The seamless interoperability with complementary technologies like Autonomous Mobile Robots (AMRs), conveyor sortation systems, and the central Warehouse Management Software (WMS).

The Anatomical Breakdown of a Modern Automated Storage and Retrieval System (AS/RS)

A high-performance Automated Storage and Retrieval System (AS/RS) functions as a cohesive unit of several critical components:

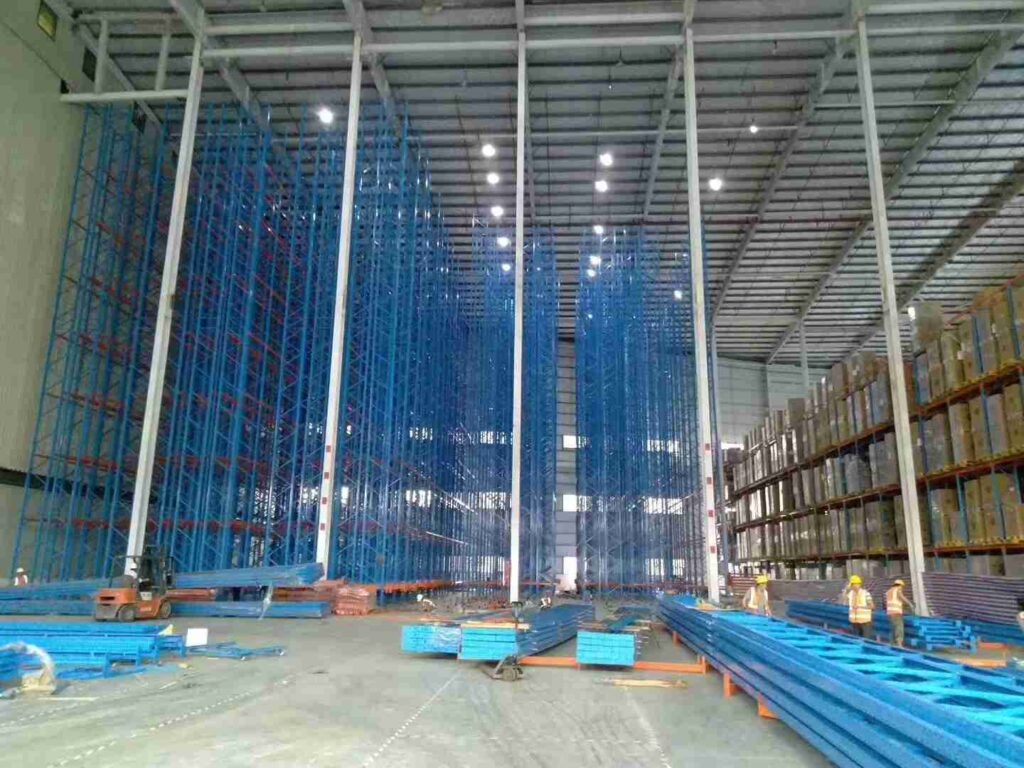

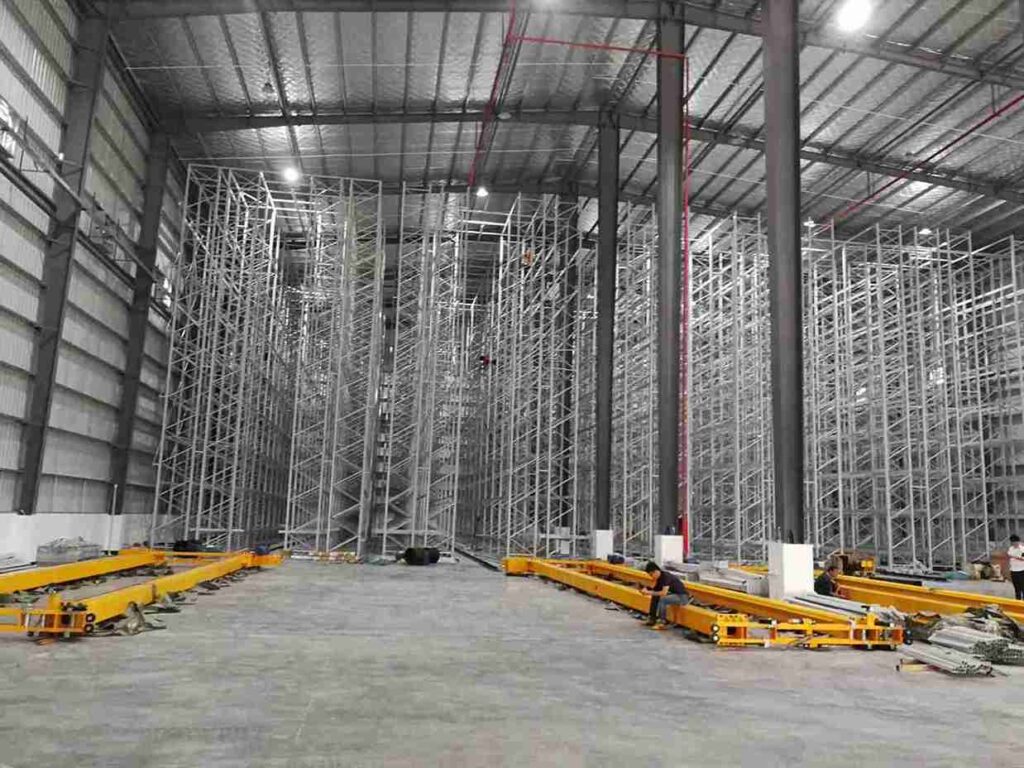

High-Density Storage Structure: This is the racking framework, engineered to exceptional standards to safely reach heights of 30 meters and beyond. Crucially, this engineering must account for the specific seismic and wind load regulations pertinent to geographically diverse nations like the Philippines, Indonesia, and Vietnam.

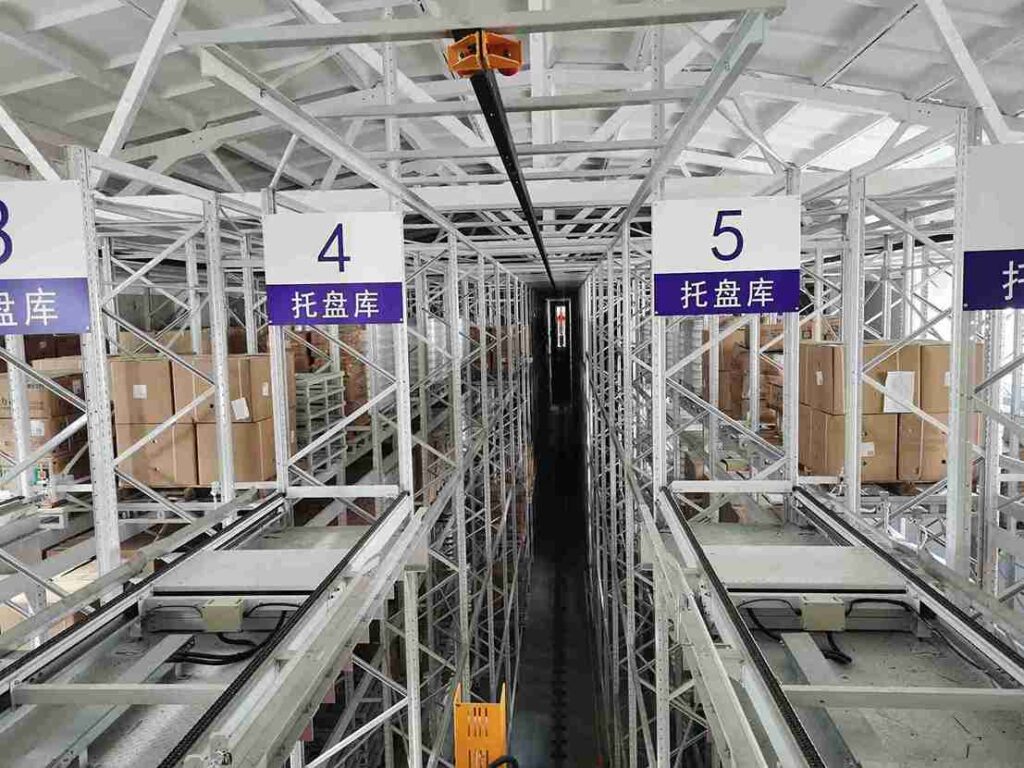

The Storage/Retrieval (S/R) Machine: Often called the aisle crane, this is the primary robotic agent. It traverses the storage aisle on precision rails. These machines are specified with tailored speeds, lift heights, and load capacities to match the specific duty cycle of the operation.

The End-Effector or S/R Mechanism: This is the device mounted on the S/R machine that physically handles the load. Designs vary significantly and can include telescoping forks, shuttle platforms, or gripping mechanisms, each selected for the specific unit load type.

The Hierarchical Control System: This is the intelligent core of the Automated Storage and Retrieval System (AS/RS). It operates on two levels: the real-time machinery control handled by robust Programmable Logic Controllers (PLCs) and the strategic optimization managed by sophisticated software that determines the most efficient sequence of operations.

The Mechanics of Transformation: How an Automated Storage and Retrieval System (AS/RS) Drives Unprecedented Value

The implementation of a tailored Automated Storage and Retrieval System (AS/RS) delivers a cascade of tangible benefits that directly address the core pain points of the Southeast Asian market.

Mastering the Cube: The Ultimate Vertical Strategy

This is the most direct and impactful benefit. While conventional racking ignores a significant portion of the building’s volume, an Automated Storage and Retrieval System (AS/RS) is inherently designed to utilize the full clear height, from floor to ceiling. This strategic approach can increase storage capacity by 200% to 400% within the exact same building footprint. The result is a dramatic reduction in the cost per pallet position, offering a powerful antidote to escalating real estate expenses.

The Aisle-Space Reclamation Project

In a manual warehouse, wide aisles are a non-negotiable requirement for forklift maneuverability, often consuming over half of the total floor area. An Automated Storage and Retrieval System (AS/RS) requires only a narrow aisle, precisely sized for the S/R machine. Advanced configurations, such as the Pallet Shuttle Systems integrated within an Automated Storage and Retrieval System (AS/RS), enable deep-lane, high-density storage serviced by a single machine, creating a near-aisle-less environment. This reclaimed floor space can be repurposed for value-adding processes like cross-docking, product kitting, or returns processing, transforming a storage facility into a dynamic distribution hub.

Achieving Near-Perfect Inventory Integrity

Imagine an operational state with 99.99% inventory accuracy. With a properly implemented Automated Storage and Retrieval System (AS/RS), this is the standard operational baseline. Every item is assigned a precise, system-managed location. The automated S/R machine executes commands with flawless accuracy, eliminating human error in location identification. This eradicates lost stock, drastically reduces shrinkage, and provides a real-time, trustworthy view of inventory levels. This precision, when integrated with a powerful WMS, unlocks advanced functionalities like:

Guaranteed FIFO/LIFO Compliance: Critical for perishable goods, food & beverage, and regulated industries.

Granular Lot and Serial Tracking: Essential for pharmaceutical, aerospace, and high-value electronics sectors.

AI-Driven Dynamic Slotting: The system automatically assigns optimal product locations based on real-time turnover data, continuously minimizing travel time for the S/R machines.

Uninterrupted Operations and Built-in Scalability

An Automated Storage and Retrieval System (AS/RS) is not constrained by human shift patterns. It can operate continuously, extending order cut-off times and maximizing daily fulfillment capacity. Furthermore, a forward-thinking Automated Storage and Retrieval System (AS/RS) design is inherently scalable. As business volumes grow, the system can be expanded modularly—by adding aisles, S/R machines, or integrating with automated conveyor and sortation systems—without a complete and disruptive overhaul.

A Portfolio of Solutions: Selecting the Right Automated Storage and Retrieval System (AS/RS) Archetype

Modern automation is not monolithic. A competent provider offers a spectrum of Automated Storage and Retrieval System (AS/RS) technologies to suit diverse operational needs and investment thresholds.

Unit-Load Automated Storage and Retrieval System (AS/RS) for Pallet-Scale Operations

This is the heavyweight champion, designed for storing full pallets of raw materials or finished goods. These robust systems form the backbone of large-scale manufacturing plants and regional distribution centers, handling the highest weights and achieving the greatest storage heights.

Mini-Load Automated Storage and Retrieval System (AS/RS) for Small-Item Fulfillment

Engineered for speed and precision, the Mini-Load Automated Storage and Retrieval System (AS/RS) is ideal for e-commerce fulfillment, spare parts logistics, and any operation managing a high-SKU count in totes or bins. These systems dramatically accelerate the order picking process for small items, which is often the primary bottleneck in e-commerce.

Shuttle-Based Automated Storage and Retrieval System (AS/RS): The Agile Performer

Systems utilizing autonomous shuttles that run within the rack structure offer an exceptional blend of density, speed, and flexibility. This type of Automated Storage and Retrieval System (AS/RS) is particularly well-suited for high-throughput environments like cold storage warehouses, a rapidly growing segment in Southeast Asia’s integrated food supply chain.

Vertical Lift Modules (VLMs) and Vertical Buffer Modules (VBMs): The Density Specialists

For the ultra-high-density storage of smaller, slower-moving items, VLMs and VBMs represent a specialized class of Automated Storage and Retrieval System (AS/RS). They consist of vertically arranged trays that are delivered automatically to an ergonomic workstation, saving immense floor space and boosting picker productivity by over 500%.

The Connected Warehouse: Integrating the Automated Storage and Retrieval System (AS/RS) into a Holistic Automation Ecosystem

An Automated Storage and Retrieval System (AS/RS) realizes its full potential when it acts as the central hub of a fully synchronized automated environment. This is where a provider’s expertise across multiple domains becomes critical.

Synergy with AGVs/AMRs: While the Automated Storage and Retrieval System (AS/RS) manages the vertical storage dimension, a fleet of Autonomous Mobile Robots (AMRs) or driverless forklifts provides the horizontal transport layer. They autonomously ferry pallets and totes between the Automated Storage and Retrieval System (AS/RS) and other zones, such as receiving, staging, or production lines.

Conveyor and Sortation Integration: For parcel and case handling, automated conveyor systems act as the arteries, seamlessly connecting the Automated Storage and Retrieval System (AS/RS) to packing workstations and shipping docks, automatically sorting items to their correct outbound destination.

The Command Center: Warehouse Execution System (WES): The true orchestrator of this complex ballet is a advanced Warehouse Execution System (WES). This software layer sits above the machinery controls, taking orders from the host ERP/WMS and translating them into a perfectly optimized sequence of tasks for every automated component, including the Automated Storage and Retrieval System (AS/RS), to maximize overall system efficiency.

The Investment Rationale: Quantifying the Return on a Custom Automated Storage and Retrieval System (AS/RS)

Capital allocation requires rigorous justification. The business case for a custom Automated Storage and Retrieval System (AS/RS) is compelling, built on a foundation of both direct financial savings and strategic advantages.

Direct (Hard) Cost Savings:

Real Estate Avoidance: The most significant saving, deferring or eliminating the need for a new, costly facility.

Labor Optimization: A reduction of 70-90% in direct forklift operator roles, allowing for strategic reallocation of personnel.

Throughput Multiplication: Operational capacity can increase by 3x to 5x, enabling revenue growth without proportional cost increases.

Error Elimination: The near-total removal of costs associated with shipping errors, inventory shrinkage, and exhaustive cycle counting.

Indirect (Soft) Cost & Strategic Benefits:

Enhanced Workplace Safety: Removing personnel from high-traffic forklift zones and high-level order picking.

Superior Customer Service: Enabling faster, more accurate order fulfillment and advanced value-added services.

Future-Proof Scalability: Creating an operational platform that can grow predictably and efficiently with demand.

Data-Driven Decision Making: Providing unparalleled, real-time visibility into inventory dynamics and operational performance.

For a majority of clients operating in the dynamic Southeast Asian market, a meticulously planned Automated Storage and Retrieval System (AS/RS) investment typically demonstrates a full return on investment (ROI) within a 2 to 4-year period, a highly attractive payback timeline given the system’s operational lifespan of 15-20 years.

A Blueprint for Success: The Automated Storage and Retrieval System (AS/RS) Implementation Journey

The path to automation is a significant undertaking, but a structured, partnership-driven approach ensures success and minimizes operational risk.

Deep-Dive Discovery and Solutioneering: The process begins not with a sales pitch, but with a forensic analysis of the client’s data, processes, pain points, and strategic objectives. This phase is dedicated to designing, not just selling, a solution.

Virtual Commissioning via Simulation: Prior to any physical installation, the entire operation is modeled in sophisticated 3D simulation software. This digital twin allows for the stress-testing of designs, the optimization of workflows, and the performance-guaranteeing of the proposed Automated Storage and Retrieval System (AS/RS) before capital is committed.

Precision Engineering and Fabrication: Detailed engineering, compliant with international and local standards, is completed. The equipment is then precision-manufactured in controlled factory environments.

Staged, Phased Installation: The installation is managed as a carefully choreographed project, designed to cause minimal disruption to the client’s ongoing business operations.

Comprehensive Knowledge Transfer and Go-Live Support: End-user training is conducted thoroughly, and dedicated 24/7 support is provided during the critical go-live phase and beyond to ensure long-term system viability and performance.

Conclusion: The Strategic Pivot from Horizontal Expansion to Vertical Optimization

The critical question for logistics and supply chain leaders in Southeast Asia has evolved. It is no longer a matter of if automation will be required, but a strategic calculation of how and when to deploy it to maximize competitive advantage. The market pressures of cost inflation, labor scarcity, and escalating customer expectations are permanent structural features of the new economy.

Persisting with manual, 20th-century warehousing methods to solve these 21st-century challenges is a recipe for obsolescence. The pathway to durable growth, operational resilience, and market leadership is paved through the intensive optimization of existing assets. A custom-engineered Automated Storage and Retrieval System (AS/RS) stands as the most potent, proven, and profitable mechanism to achieve this transformation. It is time to cease the costly cycle of horizontal expansion and to begin the intelligent work of vertical optimization. It is time to unlock the immense latent potential contained within the cubic volume of your warehouse.

Frequently Asked Questions (FAQs)

1. How does an Automated Storage and Retrieval System (AS/RS) handle the region’s humidity and temperature fluctuations, which can affect machinery and electronics?

This is a crucial engineering consideration. A high-quality Automated Storage and Retrieval System (AS/RS) designed for Southeast Asia is built with components rated for industrial environments. This includes corrosion-resistant coatings, sealed electrical connections, and environmental controls for critical subsystems. The design specification phase explicitly accounts for the local ambient conditions to ensure long-term reliability.

2. Can an existing warehouse be retrofitted with an Automated Storage and Retrieval System (AS/RS), or is a new building required?

Retrofitting is a very common and successful application. A detailed site survey is conducted to assess floor flatness, column positions, roof strength, and clear height. Often, a custom Automated Storage and Retrieval System (AS/RS) can be designed to work within these constraints. In some cases, minor structural reinforcements may be recommended, but a greenfield construction is not always necessary.

3. What happens if the central computer controlling the Automated Storage and Retrieval System (AS/RS) fails?

System resilience is paramount. A well-architected Automated Storage and Retrieval System (AS/RS) incorporates redundancy at critical levels. While the central WES/WMS optimizes tasks, the real-time PLCs that directly control the S/R machines can often continue operating based on a cached queue of tasks. Furthermore, manual recovery protocols and backup power systems are standard provisions to ensure operational continuity and a graceful recovery.

4. How does the performance of an Automated Storage and Retrieval System (AS/RS) in a multi-shift operation compare to a manual one over the long term?

The performance of a manual system degrades over a shift due to operator fatigue and can vary significantly between shifts. The performance of an Automated Storage and Retrieval System (AS/RS) is consistent, predictable, and repeatable across all shifts, 24 hours a day. Its throughput does not drop during the third shift, and it maintains its pinpoint accuracy regardless of operating hours. This predictability is a key advantage for capacity planning and meeting service-level agreements (SLAs).

5. Our product portfolio changes frequently. How adaptable is an Automated Storage and Retrieval System (AS/RS) to changing SKU profiles and inventory turnover rates?

A significant strength of a modern Automated Storage and Retrieval System (AS/RS) is its inherent flexibility. The software-driven nature of the system allows for easy re-slotting of inventory. As product velocities change, the WMS can dynamically reassign storage locations to optimize travel times. The physical system is typically designed to handle a range of load sizes and weights, providing a buffer for changes in the product mix. This software-defined flexibility makes the Automated Storage and Retrieval System (AS/RS) highly adaptable to market changes.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com