📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Is Your Warehouse Layout Costing You Money? The Ultimate Guide to Optimizing with Custom Pallet Racking Design

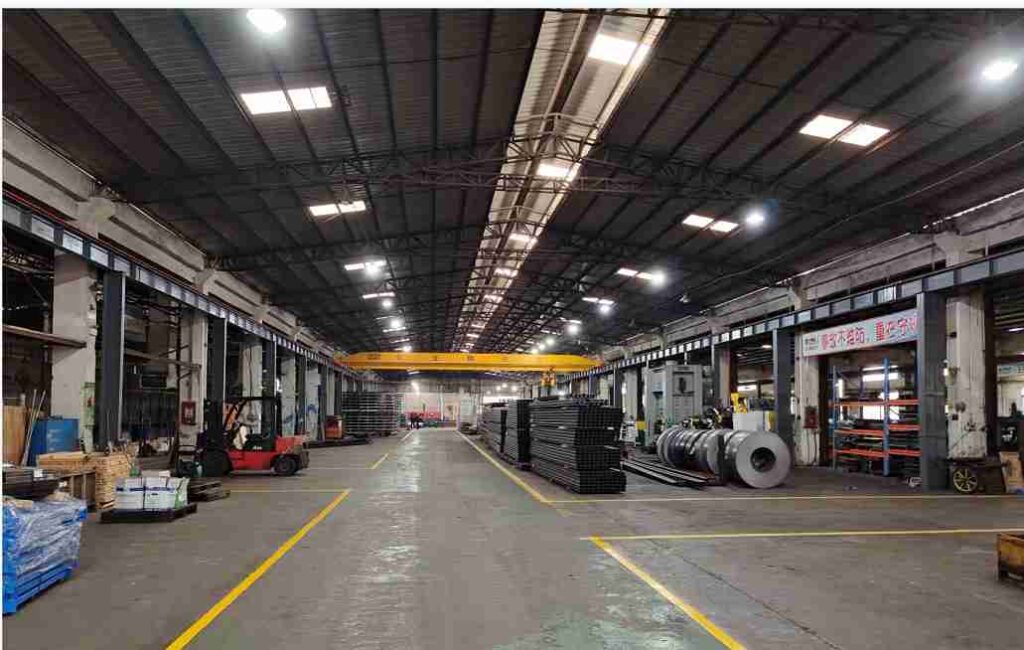

In the complex ecosystem of modern logistics, the warehouse stands as a critical nexus where efficiency either compounds profits or erodes them. A poorly conceived storage system represents far more than a simple operational inconvenience; it constitutes a persistent, silent drain on financial performance. The fundamental differentiator between a cost center and a strategic asset lies in the implementation of a professionally engineered Custom Pallet Racking Design.

This approach transcends the commodity-based purchase of shelving to embrace a holistic, data-driven methodology that re-imagines the entire storage environment. A truly effective Custom Pallet Racking Design integrates spatial optimization, workflow dynamics, inventory profiling, and future scalability into a single, cohesive operational backbone. For businesses operating in competitive markets across Southeast Asia, the Middle East, and Latin America, where logistics margins are often tight, the return on investment from a sophisticated Custom Pallet Racking Design can be the decisive factor in achieving market dominance.

The Unseen Financial Drain: Quantifying the Cost of Poor Layout

Many warehouse managers operate with a lingering sense of operational friction, yet struggle to quantify its financial impact. The reality is that an inefficient layout imposes a multi-faceted “inefficiency tax” that directly diminishes profitability. Understanding these cost centers is the first step toward justifying a transformational investment in a Custom Pallet Racking Design.

The Cubic Air Premium: Wasting the Most Expensive Real Estate

Industrial real estate is priced by the square foot, but its utility is measured in cubic feet. Facilities with high clear ceilings that are underutilized represent a profound economic waste. A standard, off-the-shelf racking solution frequently fails to capitalize on the full volumetric potential of a building. It is not uncommon to observe warehouses with 30-foot ceilings employing racking that reaches only 15 feet, effectively paying for a facility twice the necessary size.

A meticulously planned Custom Pallet Racking Design directly attacks this inefficiency by conducting a precise volumetric analysis. This analysis ensures that the storage system safely extends to within optimal clearances of the roof structure, often increasing storage capacity by 40% to 60% without expanding the building’s footprint. This strategic approach to Custom Pallet Racking Design converts wasted air into valuable inventory space.

The Travel Time Tax: How Labor Hours Vanish in Long Aisles

Labor constitutes one of the largest variable costs in any warehouse operation. In a disorganized layout, a staggering proportion of a worker’s shift can be consumed by non-productive travel. Forklift operators may spend over half their time traversing unnecessarily long or convoluted paths between receiving, storage locations, and shipping docks. This “Travel Time Tax” is compounded by time spent searching for misplaced or poorly slotted SKUs.

A scientifically developed Custom Pallet Racking Design strategically positions high-velocity SKUs in the “golden zone”—the area between knee and shoulder height—and minimizes travel distances by creating a logical, flow-oriented footprint. By optimizing these paths, a superior Custom Pallet Racking Design can reduce travel time by 30-50%, effectively freeing up labor for value-added activities and increasing overall throughput dramatically.

Safety Liabilities and Inventory Shrinkage

A cramped and illogical warehouse layout is a breeding ground for safety incidents and product damage. Cluttered aisles, insufficient lighting, and poorly organized inventory increase the risk of forklift collisions, racking impacts, and load instability. The financial consequences of a single accident—from worker’s compensation claims and equipment repair to regulatory fines and downtime—can be devastating. Furthermore, poor accessibility leads to damaged goods from improper handling or from having to move multiple pallets to reach a single SKU. A core tenet of a professional Custom Pallet Racking Design is the integration of safety-first principles, ensuring adequate aisle widths, clear visibility, and logical product placement that minimizes handling and the associated risk of damage.

Deconstructing the Blueprint: The Anatomy of a True Custom Pallet Racking Design

The term “custom” is often misapplied in the storage industry. A genuine Custom Pallet Racking Design is not merely the adjustment of standard dimensions, but a comprehensive engineering process tailored to the unique DNA of a business’s operations. It is an analytical and creative endeavor that synthesizes multiple data streams into a highly functional physical structure.

Data-Driven Slotting: The Brain of the Operation

The intelligence of any storage system lies in its slotting strategy. An effective Custom Pallet Racking Design begins with a deep analysis of the company’s inventory profile. This involves processing data on SKU velocity (how often an item is picked), cube (its physical dimensions), weight, and product affinity (which items are often ordered together). This analysis allows the Custom Pallet Racking Design team to position A-items in the most accessible locations, group related items, and assign appropriate storage media based on each product’s characteristics. This data-centric approach ensures that the physical layout of the Custom Pallet Racking Design is a direct reflection of actual demand patterns, eliminating wasteful motion and accelerating order fulfillment.

Load-Specific Engineering: The Spine of the Structure

Structural integrity is non-negotiable. Unlike generic systems rated for “average” loads, a professional Custom Pallet Racking Design involves precise structural calculations for every single component. Each upright frame and beam is specified based on the exact weight, dimensions, and distribution of the palletized loads it will support. This load-specific engineering, a critical aspect of a safe Custom Pallet Racking Design, prevents the dangerous practice of overloading while also avoiding the unnecessary expense of over-engineering. This meticulous attention to detail ensures that the Custom Pallet Racking Design is both supremely safe and cost-effective, providing a robust spine for daily operations.

Workflow Integration: The Circulatory System

A racking system should not be designed in a vacuum. It must function as the circulatory system for the flow of goods. A superior Custom Pallet Racking Design is fully integrated with the operational workflow, whether it follows a U-shaped, Through-Flow, or Modular Zone pattern. The design process maps the path of goods from receiving to staging, storage, picking, packing, and shipping, ensuring a logical, unidirectional flow that minimizes cross-traffic and congestion. This holistic view is what separates a mere storage layout from a truly transformational Custom Pallet Racking Design that enhances the entire supply chain’s velocity.

The Arsenal of Efficiency: A Deep Dive into Custom Pallet Racking Systems

The palette of available storage technologies is vast. A masterful Custom Pallet Racking Design involves the expert selection and often hybridization of these systems to create a perfect-fit solution. The following systems represent the core tools employed in a modern Custom Pallet Racking Design strategy.

Selective Pallet Racking: The Adaptive Workhorse

As the most versatile system, selective racking provides direct access to every pallet location. Its efficiency, however, is entirely dependent on its configuration. A well-executed Custom Pallet Racking Design for a selective system optimizes aisle width based on the specific material handling equipment. For instance, transitioning from a standard forklift requiring a 12-foot aisle to a narrow-aisle reach truck operating in an 8-foot aisle can instantly increase storage density by over 20%. This level of customization is a fundamental benefit of a tailored Custom Pallet Racking Design, fine-tuning the most common system for maximum performance.

Narrow Aisle & Very Narrow Aisle (VNA) Racking: The Density Pioneers

When floor space is extraordinarily valuable, a Custom Pallet Racking Design will often leverage Narrow Aisle or VNA solutions. These systems, which require specialized equipment like turret trucks or order pickers, reduce aisle widths to as little as 5-6 feet. The resulting storage density can be 40-50% higher than standard selective layouts. The Custom Pallet Racking Design for a VNA application is highly precise, accounting for the exact turning radius of the equipment and laser-guided vehicle (LGV) tolerances to ensure safe, high-speed operation within these tight confines.

Drive-In & Drive-Thru Racking: The High-Density Champions

For businesses storing large quantities of a limited number of SKUs, such as in the beverage or cold storage industries, Drive-In and Drive-Thru racking offer unparalleled density. In this Custom Pallet Racking Design, forklifts drive directly into the rack structure to deposit or retrieve loads, eliminating multiple aisles. The engineering of a Drive-In/Drive-Thru system is a complex task, involving calculations for lane depth, number of pallet levels, and the specific dynamic loads imposed by the forklift. A properly engineered Custom Pallet Racking Design for this application balances immense storage density with structural integrity and operational accessibility.

Push-Back Racking: The Strategic Compromise

Push-Back racking represents an ingenious solution in the Custom Pallet Racking Design toolkit, offering a blend of selectivity and high density. Pallets are stored on nested carts on inclined rails, allowing for 2-5 pallets of depth per lane. When a pallet is retrieved, the next one automatically rolls forward. This Custom Pallet Racking Design is ideal for medium-velocity SKUs where multiple pallets of the same product are kept on hand but immediate access to each SKU is still required. The design complexity involves ensuring smooth cart movement and proper load distribution, a task for experienced Custom Pallet Racking Design engineers.

Flow Racking: The Velocity Engine

For high-throughput operations requiring perfect FIFO (First-In, First-Out) inventory management, Pallet Flow is a premier choice in a Custom Pallet Racking Design. Using gravity-fed rollers, pallets move from the load side to the pick face automatically. This system dramatically reduces picking time and ensures optimal stock rotation. The engineering behind a Pallet Flow Custom Pallet Racking Design is nuanced, requiring precise calculation of roller pitch, braking zones, and decline angles to accommodate varying product weights and ensure a controlled, consistent flow without risk of impact damage.

he Tangible Return: Calculating the ROI of a Custom Pallet Racking Design

Investing in a comprehensive Custom Pallet Racking Design is a capital decision with a demonstrable and often rapid return. The investment pays for itself across several key financial vectors, making a compelling business case beyond mere storage.

Capitalizing on Existing Assets: The Real Estate Dividend

The most immediate financial return from a Custom Pallet Racking Design often comes from the deferral or avoidance of costly facility expansions. By radically increasing storage density within the existing building envelope, companies can postpone multi-million dollar investments in new construction or leasing. In some cases, a high-density Custom Pallet Racking Design even enables the consolidation of multiple distribution centers into a single, highly efficient facility, generating massive, ongoing savings in rent, utilities, and property taxes.

The Labor Productivity Multiplier

The efficiency gains from a logical, optimized Custom Pallet Racking Design directly translate into labor savings. By reducing travel and search times by 30-50%, the same workforce can achieve significantly higher throughput. For a company with a $500,000 annual labor budget in its warehouse, a 30% efficiency gain equates to $150,000 in effectively liberated labor value—either as direct cost savings or as increased capacity to handle growth without adding headcount. This labor multiplier effect is a cornerstone of the ROI calculation for any serious Custom Pallet Racking Design project.

Mitigating Risk and Reducing Operational Waste

The financial benefits of a Custom Pallet Racking Design also include risk mitigation. A safer warehouse leads to lower insurance premiums, fewer accident-related costs, and less unplanned downtime. Furthermore, reduced product damage from less handling and improved organization flows directly to the bottom line. The combination of these “soft” savings can be substantial, further accelerating the payback period for the investment in a professional Custom Pallet Racking Design.

A Partnership in Process: The Journey to Your Custom Pallet Racking Design

Achieving these transformative results requires a structured, collaborative partnership. The development and implementation of a world-class Custom Pallet Racking Design follows a disciplined, phased approach designed to minimize disruption and maximize success.

Phase 1: Immersive Discovery and Data Interrogation

This foundational phase is where the Custom Pallet Racking Design is conceptually born. It extends far beyond simple facility measurements. It involves a deep audit of operational data, including: Inventory Analysis: A thorough review of SKU data, including dimensions, weight, velocity, and seasonality. Workflow Mapping: A detailed observation and mapping of all material and personnel flows to identify bottlenecks. Facility Assessment: Precise laser-scanning of the building to capture clear heights, column placements, and door locations. Future-State Planning: Strategic discussions about business growth plans, new product lines, and potential automation to ensure the Custom Pallet Racking Design is scalable and future-proof.

Phase 2: Dynamic Modeling and Engineering Simulation

In this phase, the conceptual Custom Pallet Racking Design becomes a virtual reality. Using state-of-the-art CAD and simulation software, engineers create a dynamic 3D model of the proposed warehouse. This “digital twin” allows stakeholders to take a virtual walkthrough of their future operation. More importantly, simulation software can model weeks of order volume in minutes, stress-testing the Custom Pallet Racking Design against real-world demand patterns to predict throughput gains and identify potential constraints before any physical installation begins.

Phase 3: Phased Implementation and Operational Transition

Execution is where a great Custom Pallet Racking Design becomes a tangible asset. Expert project managers develop a meticulous, phased installation plan that allows the business to continue operating throughout the transition. This involves careful sequencing of demolition (if required), new racking installation, and inventory transfer. The goal is a seamless cut-over to the new **Custom Pallet Racking Design with minimal impact on daily shipping and receiving schedules, turning the blueprint into a live, profit-enhancing operation.

The Automated Frontier: Custom Pallet Racking Design as the Foundation for Robotics

A modern Custom Pallet Racking Design is not an endpoint; it is the foundational layer for the next evolution in logistics: automation. The structural precision of a well-designed racking system is a prerequisite for the successful integration of advanced technologies.

Designing for AGVs and Autonomous Mobile Robots (AMRs)

When a Custom Pallet Racking Design is created with the future integration of Automated Guided Vehicles (AGVs) or Autonomous Mobile Robots (AMRs) in mind, the tolerances become exponentially tighter. Aisles must be perfectly straight, level, and dimensioned with millimeter-level precision. The racking itself can be engineered with embedded guidance features or fiduciary markers to assist in robotic navigation. This forward-looking Custom Pallet Racking Design ensures that the transition to a semi- or fully-automated warehouse is a logical upgrade, not a costly retrofit.

The Symbiosis with Automated Storage and Retrieval Systems (ASRS)

For the ultimate expression of density and speed, a Custom Pallet Racking Design evolves into the fixed infrastructure of an Automated Storage and Retrieval System (ASRS). In this scenario, the racking is no longer a passive storage structure but an active component of the machine. It provides the rails and support for the automated cranes that run within it. The engineering rigor for an ASRS-based Custom Pallet Racking Design is extreme, requiring flawless vertical and horizontal alignment to allow cranes to operate at high speeds with absolute precision. This represents the pinnacle of what a sophisticated **Custom Pallet Racking Design** can achieve.

Conclusion: From Cost Center to Competitive Advantage

The evidence is clear and compelling. The decision to invest in a professional Custom Pallet Racking Design is a strategic move to eliminate a significant, hidden operational tax and convert the warehouse from a passive cost center into a dynamic competitive advantage. The continuous costs of wasted space, labor inefficiency, and preventable losses will persistently undermine profitability and growth potential. A scientifically engineered Custom Pallet Racking Design unlocks latent capacity, amplifies workforce productivity, and creates a resilient, scalable platform capable of supporting future growth and technological adoption.

In global markets where logistics excellence is a key differentiator, the sophistication of a company’s Custom Pallet Racking Design is increasingly a proxy for its overall operational maturity and ambition. The question is no longer if a business can afford to implement a superior Custom Pallet Racking Design, but how long it can afford to operate without one.

Frequently Asked Questions

What is the typical lead time from the initial design concept to a fully operational custom racking system?

The complete project lifecycle for a comprehensive Custom Pallet Racking Design and implementation typically ranges from 10 to 20 weeks. The initial design and engineering phase requires 3-5 weeks to ensure all data is accurately incorporated. Manufacturing of the custom-specified components usually takes 5-8 weeks, followed by a coordinated on-site installation lasting 2-4 weeks, depending on the project’s scale and complexity.

How does a custom design account for future expansion or changes in our product mix?

A hallmark of a professional Custom Pallet Racking Design is its inherent scalability. Design engineers incorporate flexibility by using standardized, readily available components where possible and planning for logical expansion zones. The structural design often includes capacity for additional height or bay extensions. Furthermore, the data-driven model behind the original Custom Pallet Racking Design can be updated as your product mix evolves, allowing for re-slotting and reconfiguration within the existing flexible framework.

We have unique product shapes and sizes that don’t fit standard pallets. Can a custom design accommodate this?

Absolutely. Addressing non-standard load types is a primary reason to pursue a Custom Pallet Racking Design. Engineers can design and specify specialized decking, cantilever arms for long loads, custom-sized beams, and unique support structures to safely and efficiently handle drums, rolls, oversized boxes, or other irregularly shaped items that fall outside the scope of conventional pallet racking.

What is the role of a Warehouse Management System (WMS) in a custom racking environment?

A WMS and a Custom Pallet Racking Design are symbiotic. The Custom Pallet Racking Design creates the optimized physical landscape, while the WMS acts as its intelligent digital brain. The WMS directs operators to the precise locations defined by the Custom Pallet Racking Design’s slotting strategy, enforces put-away rules, and optimizes pick paths. The data generated by the WMS can also be used to continuously refine and improve the **Custom Pallet Racking Design** over time, creating a cycle of continuous optimization.

How do you ensure that the proposed custom design will actually deliver the projected ROI?

The projection of ROI in a professional Custom Pallet Racking Design proposal is based on a quantitative analysis of your current operational metrics (e.g., travel times, picking rates, space utilization). The before-and-after simulation models provide a data-backed forecast of efficiency gains. Furthermore, reputable providers will base their design on measurable KPIs and can structure post-implementation audits to verify the achieved results in labor savings, capacity increase, and throughput improvement, ensuring the Custom Pallet Racking Design delivers on its promised financial return.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com