📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Integrating Automation for a Seamless High-Density Storage Ecosystem

A high-density storage system does not operate in a vacuum. Its true potential is unlocked when it is seamlessly integrated with other automated material handling technologies. This creates a fluid, end-to-end ecosystem that minimizes human intervention and maximizes throughput. For companies looking beyond simple space savings towards total operational transformation, this integration is the ultimate goal.

Consider the workflow: pallets arrive at the receiving dock. Instead of a forklift driver transporting them to a random location, an AGV car or unmanned forklift takes charge. Guided by a sophisticated Warehouse Management System (WMS), this autonomous vehicle transports the load directly to the intake point of the high-density storage system, be it an ASRS induction station or a pallet shuttle lane. This “first touch” automation eliminates a significant portion of manual labor and potential damage.

Similarly, for order fulfillment, the process is reversed. The high-density storage system automatically retrieves the required items and presents them at a pick station. From there, goods are transferred onto an automated sorting system or automated conveyor systems, which route them to the appropriate packing and shipping lanes. This seamless handoff between different automated technologies—from storage to sorting—creates a continuous, high-velocity flow of goods. It is this holistic approach to high-density storage integration that allows companies to achieve the coveted 24/7 “lights-out” warehouse operation, a concept rapidly gaining traction in advanced logistics hubs across the Middle East and Southeast Asia.

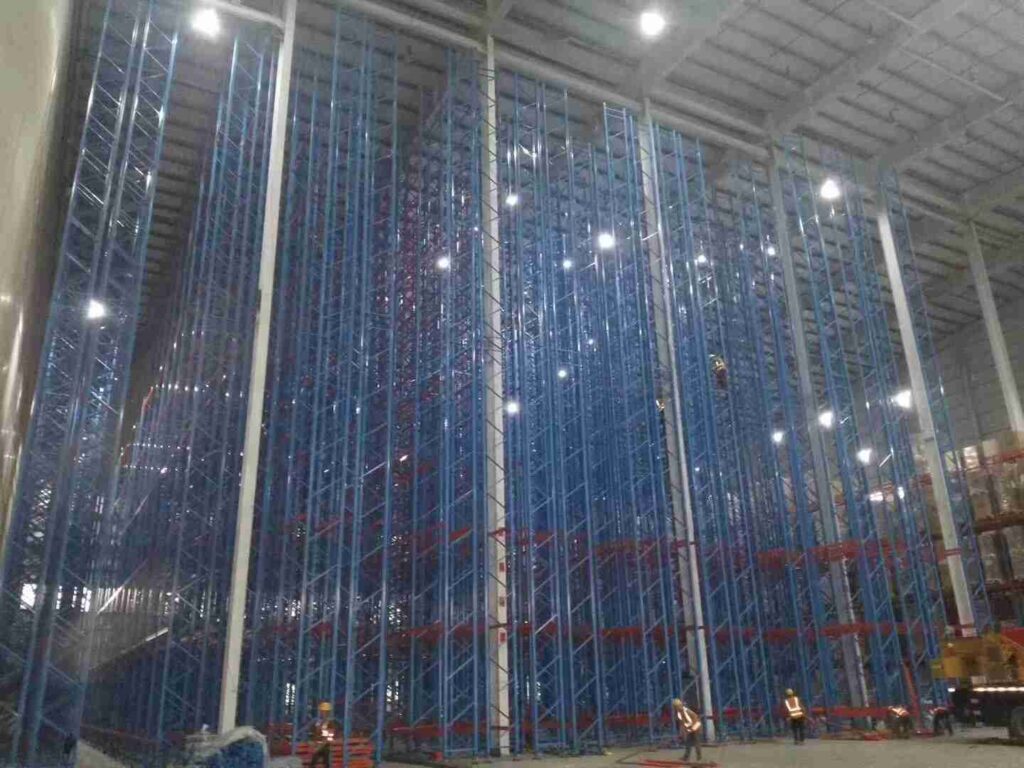

The Critical Role of Structural Engineering and Safety in High-Density Storage

The immense concentration of weight in a high-density storage installation places extraordinary demands on a building’s structure and the racking system itself. Therefore, the engineering phase is not a mere formality; it is the bedrock upon which safety, reliability, and longevity are built. A failure in structural integrity is not an option, making this a non-negotiable aspect of any high-density storage project.

Prior to installation, a thorough structural analysis of the warehouse is imperative. This includes assessing the floor slab’s load-bearing capacity, its flatness (FF/FL levels), and the location and strength of supporting columns. The foundation for a high-density storage system, particularly a multi-level mezzanine or a heavy-duty ASRS, must be designed to handle dynamic and static loads far exceeding those of traditional racking. In regions prone to seismic activity, such as parts of Latin America and Southeast Asia, additional engineering for seismic bracing is absolutely critical.

Furthermore, the high-density storage structures themselves must be manufactured to the highest tolerances using high-grade steel. Safety features are paramount. These include:

Heavy-Duty Column Guards: To protect upright frames from impact.

Pallet Safety Grates: To prevent pallets from being dislodged at higher levels.

Aisle End Protectors and Signage: To mark zones and prevent collisions.

Integrated Fire Suppression Systems: Especially crucial in enclosed ASRS where traditional sprinkler systems may be less effective.

A properly engineered high-density storage system is not just about storing more; it’s about storing more, safely and reliably for decades to come. This commitment to safety and quality is a core tenet of a reputable supplier’s offering.

Data-Driven Design: The Blueprint for High-Density Storage Success

The design of an effective high-density storage system is not based on guesswork or generic templates. It is a precise, data-driven science. The old adage “garbage in, garbage out” holds profoundly true; the quality of the output—the system’s design—is directly dependent on the quality and granularity of the input data.

A world-class high-density storage provider will conduct an exhaustive analysis of a client’s inventory profile. This goes far beyond a simple list of SKUs. It involves capturing and analyzing:

SKU Velocity (ABC Analysis: A clear breakdown of fast (A), medium (B), and slow (C) moving items.

Dimensional and Weight Data: Precise length, width, height, and weight for every SKU, including variations in packaging.

Seasonality and Forecasted Growth: Understanding peak seasons and projected business growth to ensure the high-density storage system is scalable and can handle future demand.

Inventory Turnover Rates: How quickly stock rotates, which influences the choice between FIFO and LIFO high-density storage systems.

With this data, engineers use advanced simulation software to model the entire operation. They can run “digital twins” of the warehouse to test different scenarios, identifying potential bottlenecks in the high-density storage workflow before a single piece of steel is erected. This simulation can optimize the number of pallet shuttles required, the speed of the ASRS cranes, and the interaction points with automated conveyor systems. This data-driven approach de-risks the investment and guarantees that the final high-density storage solution is perfectly tailored to the unique and dynamic needs of the business, ensuring that the promised efficiency gains are not just theoretical but are engineered into the system from day one.

Overcoming Implementation Hurdles: A Guide to a Smooth High-Density Storage Transition

The transition to a high-density storage environment is a significant operational shift. Acknowledging and proactively managing the challenges of implementation is key to a successful project. Resistance to change, data migration complexities, and the need for new skill sets are common hurdles that must be addressed with a clear strategy.

Phased Implementation: A “big bang” switchover is often too disruptive. A phased approach is vastly preferable. This might involve installing the new high-density storage system in one section of the warehouse while the old system remains operational in another. Inventory can be gradually migrated, and staff can be trained on the new system without bringing the entire operation to a halt.

Change Management and Training: The workforce may view automation and high-density storage with apprehension. Transparent communication about the strategic reasons for the change and the long-term benefits for the company and its employees is crucial. Comprehensive training programs are not an expense; they are an investment. Operators must be trained not just to use the new system, but to understand it, troubleshoot minor issues, and trust its processes. This empowers them and turns potential adversaries into advocates for the new high-density storage technology.

Data Integrity and WMS Configuration: The new high-density storage system will be entirely dependent on the accuracy of the WMS and the underlying inventory data. The implementation phase must include a rigorous data cleansing and validation process. Configuring the WMS rules—such as put-away logic, picking waves, and replenishment triggers—is a collaborative effort between the client’s logistics team and the solution provider’s software engineers. Getting this right is what makes the high-density storage system intelligent rather than just a passive storage structure.

The Financial Calculus: Analyzing the Total Cost of Ownership (TCO) for High-Density Storage

When evaluating a high-density storage solution, savvy business leaders look beyond the initial capital expenditure. The true measure of value is the Total Cost of Ownership (TCO) over the system’s lifespan, which often reveals a compelling financial case.

Capital Expenditure (CapEx): This is the upfront cost for the high-density storage equipment, software, installation, and any necessary building modifications. While higher than traditional racking, it must be compared against the avoided cost of building a new facility.

Operational Expenditure (OpEx): This is where high-density storage systems shine. Significant and ongoing savings are realized through:

Labor Reduction: Fewer forklift operators and order pickers are needed.

Energy Efficiency: A smaller, more densely packed footprint costs less to heat, cool, and light. Automated systems can often operate in near-darkness.

Space Savings: Eliminating the need for expansion defers or eliminates massive capital outlays.

Error Reduction: The financial impact of mis-picks, lost inventory, and shipping errors is drastically minimized.

Maintenance and Support: A predictable, ongoing cost for scheduled maintenance, software support, and spare parts ensures peak performance and long-term reliability of the high-density storage system.

A detailed TCO analysis typically shows that while the initial investment for a sophisticated high-density storage system is substantial, the dramatic reduction in OpEx leads to a strong ROI and a lower overall TCO compared to maintaining an inefficient, labor-intensive traditional warehouse. This financial model makes a powerful argument for the economic superiority of advanced high-density storage solutions.

Conclusion: Positioning Your Enterprise for the Future with High-Density Storage

In the relentless pursuit of supply chain excellence, standing still is not an option. The challenges of rising costs, space constraints, and customer demands for speed are only intensifying on a global scale. In this context, the strategic implementation of a high-density storage system transitions from being a tactical equipment upgrade to a cornerstone of long-term competitive strategy.

The journey to a superior high-density storage solution requires a partnership with a provider that possesses not just product knowledge, but deep industry expertise, proven engineering capabilities, and a global perspective. It requires a collaborator who understands the nuances of markets from Nigeria to Chile, and from Indonesia to the UAE. By embracing the principles of high-density storage, businesses are not merely buying racking and software; they are investing in a resilient, scalable, and supremely efficient operational backbone.

They are choosing to maximize their existing assets, empower their workforce with technology, and build a logistics operation capable of thriving in the complex economic landscape of the 21st century. The question is no longer if a company should move towards high-density storage, but how soon it can begin this critical transformation.

Frequently Asked Questions (FAQs)

1. How does high-density storage impact order picking efficiency for slow-moving items (C-Items)?

High-density storage systems, particularly mobile racking or ASRS, are exceptionally efficient for slow-moving inventory. These items can be stored in the most space-efficient areas of the system, regardless of accessibility. When an order for a C-item arrives, the WMS directs the system to retrieve it automatically. This eliminates time wasted by workers searching remote corners of a warehouse, actually making the picking process for slow-movers faster and more accurate than in a conventional setup.

2. Can a high-density storage system be reconfigured if our business needs or inventory profile changes?

Modularity is a key feature of modern high-density storage solutions. While systems like Drive-In racks are relatively fixed, pallet shuttle systems can be reconfigured by adjusting lane depths. Mobile racking systems can be extended or rearranged. The greatest flexibility lies in the software; the WMS can be re-programmed to adapt to new SKUs, changed velocity profiles, and altered workflow patterns, ensuring the high-density storage system evolves with your business.

3. What are the energy consumption implications of operating an automated high-density storage system?

There is a dual effect. The physical high-density storage structure, by condensing the storage footprint, significantly reduces energy needs for lighting and climate control. The automated components (shuttles, cranes) do consume electricity, but they are designed for high energy efficiency, often using regenerative braking similar to electric vehicles. The net effect is almost always a substantial reduction in total energy consumption per pallet stored or per order picked.

4. How does high-density storage handle non-standard or awkwardly shaped loads?

High-density storage is highly adaptable. For non-palletized loads, systems like cantilever racking can be integrated for long items. For awkward shapes, custom-designed trays or containers are used within an ASRS or on mobile shelving. The initial data analysis phase is critical to identify these special cases, allowing the high-density storage system to be engineered with the appropriate attachments and storage media to handle the entire inventory portfolio effectively.

5. What is the scalability of a high-density storage solution? If we outgrow it, what are the options?

Scalability is a fundamental design consideration. A well-planned high-density storage system is inherently scalable. Vertical scalability is achieved by building the structure higher. Horizontal scalability can be achieved by extending the system laterally if floor space allows. Throughput scalability is enhanced by adding more retrieval machines or shuttles. During the design phase, a reputable provider will create a roadmap for future expansion, ensuring the initial high-density storage investment is protected and can grow in lockstep with the business.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com